TOWER SYSTEM LCC44/LCC84 WALL INSTALLATION

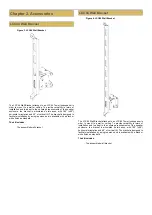

Mounting the bracket

The mounting plate of the LCC44/84 Wall Bracket must be firmly fitted to

the wall or surface before mounting and pointing the speaker enclosure.

WARNING

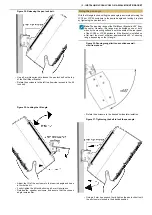

Before beginning this installation, it is necessary to

ascertain the construction type, load-bearing capability

and durability of the wall or surface. Bear in mind that

the LCC44 speaker enclosure weighs 10 kg (22 lb)

and LCC84 weighs 19.5 kg (43 lb). The Wall Mount

Bracket is also capable of downward tilt that extends

the mass of the enclosure up to a 40° angle out from

the mounting surface. Therefore, the increased forces

imposed on the fixings and wall must be taken into

account.

Careful thought must be given to ensure that the

wall structure is strong enough to safely support the

total load with the proper Factor of Safety required

by local, state and national norms or legislation. If

the facility or venue is open to the public and the

mount is within reach of the public, the installer should

take into consideration possible miscreant behavior or

tampering when determining the appropriate factor of

safety. If the wall structure is deemed incapable of

supporting the load, consideration should be given to

strengthening and/or stabilizing the wall or adopting

an alternative method of installation. In the case of

any doubt, architects, structural engineers or other

specialists should be consulted.

WARNING

Risk of Electric Shock

Drilling into hidden electrical wiring within walls can

result in serious injury or death, fires and property

damage.

BE AWARE OF WHAT YOU ARE DRILLING INTO.

Before drilling holes in any wall or surface, make sure

that it does not conceal electrical wiring or conduits.

Consult the wiring diagram of the facility or venue and

check for nearby outlets, switches or junction boxes

that could indicate concealed wiring, be it electrical

mains, network, telephone or other infrastructure.

CAUTION

Use Proper Eye, Ear, Head, Foot and Hand Protection

During Installation

This task may require the use of power tools and

potentially elevated loads.

All local and national norms, regulations and guidelines

must be followed during the installation procedures,

including the use of proper protective clothing and

gear.

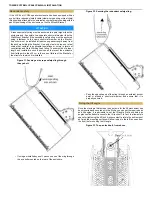

Notice: Due to the wide variety of building materials and

construction methods that can be encountered in an installation,

1 Sound can only provide general recommendations for installing

the Wall Mount Bracket. It is the responsibility of the installer to

assess the appropriate stability and sturdiness of the installation.

This includes verifying the positions of suitable studs, posts

or framing in the case of drywall mounts, verifying hollow

points in masonry, concrete block or solid concrete, and

utilizing anchoring methods and hardware appropriate for safe

installation of the equipment according to the construction

material and depth of the mounting surface. The responsibility

rests with the installer to verify that the installation is carried

out in accordance with any applicable legislation. In case of any

doubt, architects, structural engineers or other specialists should

be consulted.

Notice: In the case of installation in solid concrete, concrete

block or masonry structures, due to the size of the mounting

plate and the narrow distance between the mounting holes

in the plate, the use of expansion anchors (sleeve anchors,

wedge anchors, plastic anchors etc.) is not recommended, as

the proximity between them is likely inferior to safe spacing

practices for this type of fastener, and could potentially weaken

the mounting surface. Verify the building material, as well as

its depth and condition to determine the appropriate anchoring

system. Make sure that the fasteners include washers or have

flanged heads with adequate outer diameter (from 14 mm to 16

mm) to firmly hold the mounting plate around the holes. Consult

the specifications of the third-party hardware and carefully follow

the instructions of the manufacturer to determine the appropriate

drilling depth, bit diameter, necessary spacing and any further

specific instructions or additional necessary procedures.

Important: In the case of a wall constructed of drywall or

other panels on a wooden stud frame, it is extremely important

to verify that the desired installation point has sufficient solid

backing to support the installed speaker enclosure. DO NOT

install the mount on unbacked drywall, plywood or plastered

lath. A studfinder can be useful for this, but it is better to know

the exact layout of the frame beforehand. The center-to-center

width between the mounting holes of the Wall Mount Bracket is

1.89" (48 mm), and therefore wider than standard 2x4 (1.5" x

3.5") or 2x6 (1.5" x 3.5") wooden framing studs. Therefore, it is

only possible to mount the plate onto other framing members with

doubled or wider widths, such as doubled posts or column studs,

corner posts, doubled jamb/king studs, solid lintels, or purpose-

built internal framing. Be careful to assure that all four mounting

holes will be drilled into the solid wood frame. Joints between

single studs and single horizontal noggings or fireblocks could be

deceptive and provide a mounting position with only three of the

screws in solid wood and the fourth only in drywall – an unsafe

condition.

Be sure to verify the depth of drywall (commonly 0.5 inches or

6.35 mm) in front of the load-bearing studs and consider this

in selecting the length of the fastener necessary. Consult the

specifications of the third-party hardware to verify the necessary

depth to guarantee the required safety factor, but remember that

it is unwise and potentially hazardous to exceed the depth of the

framing member into which the anchor is driven.