TOWER SYSTEM LCC44/LCC84 WALL INSTALLATION

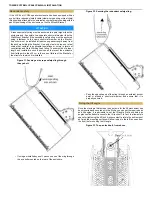

Figure 23. Driving the screw anchors into the wall.

•

While holding the plate in place, use a socket wrench or a power

screwdriver to tighten each fastener gradually, alternating

diagonally opposed fasteners in an "X" pattern until each holds

the plate to the wall. When using a power driver, keep it at a

low speed to avoid stripping the threading cut into the substrate

material. Once the washer or flanged head on each bolt is in

contact with the plate and the plate is against the wall, continue

tightening them only by hand.

Figure 24. Tightening the screw anchors with a

torque wrench.

•

Using a torque wrench, tighten each screw anchor into the

wall. Take care not to exceed the maximum installation torque

specified by the manufacturer of the hardware.

Figure 25. Applying downward force to verify the

mount.

•

Apply force or weight to the mounting plate to physically verify

its ability to support the necessary load. There must be no

movement possible between the plate and the wall.

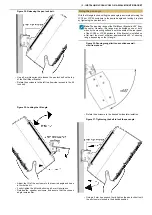

Coupling the LCC enclosure and bracket to the mounting

plate

Once the mounting bracket has been installed on the LCC84 or LCC44

and the mounting plate has been secured to the mounting surface, the

speaker enclosure can be mounted on the wall.

Figure 26. Installing the LCC44 with the bracket

onto the mounting plate.