Chapter 1. Speaker models

TOWER LCC44

Cardioid Column Line Array Enclosure

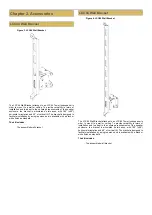

Figure 1. LCC44 with Tower Rigging System (left),

and without.

Tower LCC44 is a cardioid line array element featuring designed to be

compact, high powered and array-able. The enclosure features Clarity

Technology©, a proprietary high frequency technology built around

four coaxial transducers each composed of a 4" cone driver and a

compression driver. The enclosure provides 120° horizontal coverage

on axis. Three additional rear 4" full-range transducers allow the unit

to provide a cardioid dispersion pattern with -20 dB rear cancellation.

The Towers can be deployed independently or combined using the

proprietary Tower Rigging System to create long column arrays. Each

LCC44 unit requires two amplifier channels operating with a dedicated

DSP preset in order to achieve the cardioid dispersion pattern.

TOWER LCC44 Specifications

Description Cardioid line array column featuring Clarity Technology© high

frequency

Bandwidth

105 Hz – 18 kHz (-6 dB)

Max SPL

123 dB SPL @ 1 m w/ preset (1 unit)

Power

800 watts front + 400 watts rear (continuous), 400 watts + 200

watts (AES)

Directivity

120° horizontal

Elements

(4) 4" coaxial each with a 1.4" compression driver, (3) 4" rear-

facing full range

Impedance

16 Ω front speakers, 24 Ω rear speakers

Connectors (4) NL4, 1+/1- front, 2+/2- rear, each allowing for audio inputs

and linking

IP Rating

IP55 indoor/outdoor and salt water resistant

Rigging

Proprietary rigging elements and fly bars -3°, 0°, +3°, +6°,

+9°; (14) available M6 points

Weight

22 lb / 10 kg

Construction Finland birch plywood (phenolic glue), structural stainless

steel interior, polyurea, clear matte salt and UV resistant coat

ing, 316 stainless steel hardware, 3D spacer mesh fabric

Accessories LCC44 Wall Bracket, Tower Tube Mount, Tower Rigging Sys

tem, Fly Bar (Long & Short), Active Speaker Tube (various

lengths)

Dimensions 17.8" (452 mm) x 6.3" (160 mm) x 9.5" (240 mm)

Colors

Stocking black and white, custom colors and fabrics available

TOWER LCC84

Cardioid Column Line Array Enclosure

Figure 2. LCC84 with Tower Rigging System (left),

and without.

Tower LCC84 is a cardioid line array element featuring designed to be

compact, high powered and array-able. The enclosure features Clarity

Technology©, a proprietary high frequency technology built around

eight coaxial transducers each composed of a 4" cone driver and a

compression driver. The enclosure provides 120° horizontal coverage on

axis. Six additional rear 4" full-range transducers allow the unit to provide

a cardioid dispersion pattern with -20 dB rear cancellation. The Towers

can be deployed independently or combined using the proprietary Tower

Rigging System to create long column arrays. Each LCC84 unit requires

two amplifier channels operating with a dedicated DSP preset in order to

achieve the cardioid dispersion pattern.

TOWER LCC84 Specifications

Description Cardioid line array column featuring Clarity Technology© high

frequency

Bandwidth

105 Hz – 18 kHz (-6 dB)

Max SPL

127 dB SPL @ 1 m w/ preset (1 speaker)

Power

1600 watts front + 800 watts rear (continuous), 800 watts +

400 watts (AES)

Directivity

120° horizontal

Elements

(8) 4" coaxial each with a 1.4" compression driver, (6) 4" rear-

facing full range

Impedance

8 Ω front, 12 Ω rear

Connectors (4) NL4, 1+/1- front speakers, 2+/2- rear speakers, each al

lowing for audio inputs and linking

IP Rating

IP55 indoor/outdoor and salt water resistant

Rigging

proprietary rigging elements and fly bars -3°, 0°, +3°, +6°, +9°;

(14) available M6 points

Weight

43 lb / 19.5 kg

Construction Finland birch plywood (phenolic glue), structural stainless

steel interior, polyurea, clear matte salt- and UV-resistant

coating, 316 stainless steel hardware, 3D spacer mesh fabric

Accessories LCC84 Wall Bracket, Tower Tube Mount, Tower Rigging Sys

tem, Active Speaker Tube

Physical

36.8" (934 mm) x 6.3" (160 mm) x 9.5" (240 mm)

Colors

Stocking black and white, custom colors and fabrics available