Chapter 3. Installing LCC44/LCC84

on a Wall Mount Bracket

Critical information

Attention: This wall-mount bracket is intended for installation by

qualified professionals.

Notice: Please read these instructions carefully and completely

before attempting installation.

WARNING

Improper installation or suspension of any heavy load

can result in death or serious injury to persons, as well

as damage to property.

It is the responsibility of the installation personnel to

verify and guaranty the reliability and safety of the

installation.

Notice: This product must be installed in compliance with all

applicable local, state and national regulatory provisions. The

responsibility rests with the installer to verify that the installation

is carried out in accordance with any applicable legislation.

Important: The installer must assess the appropriate stability

and sturdiness of the mounting surface. In the case of wall-mount

and ceiling-mount brackets, this includes, but is not limited to

verifying the positions of suitable studs in the case of drywall

mounts, hollow points in concrete block or solid concrete, as well

as the presence and vicinity of electrical wiring or plumbing.

Restriction: Only hardware and accessories included with

the product or specified by 1 Sound should be used for its

installation.

Restriction: Do not modify or alter the loudspeaker or any

accessory. Any modification by the user or installer could render

the product or the installation unsafe.

Restriction: Do not install a loudspeaker or any accessory near

any open flame or heat source.

Products, accessories and tools required

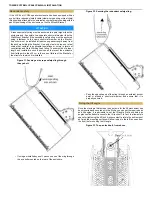

To install an LCC44 or LCC84 enclosure permanently on a wall or surface

you will need the following:

•

An

or

enclosure

•

The corresponding

or

kit

•

An appropriate power drill and bit for the installation surface

material

•

A 5 mm hex (Allen) wrench

•

Medium-duty mounting screws or bolts appropriate to the

mounting surface (coach screws for drywall studs, concrete

screw anchors for concrete or masonry, etc.); screws and bolts

should have a flanged head or a coupled washer ø14-16 mm in

order to retain the mounting plate

•

Appropriate tools for securing the aforementioned fasteners

(power screwdriver etc.)

•

A Torque wrench

•

Optional: 4 mm hex (Allen) wrench, steel rope sling or chain, M6

lifting eye bolt (shouldered type); eye bolt spanner or driver

•

Recommended: pencil or marker, spirit level, stud finder

Procedures

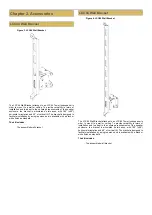

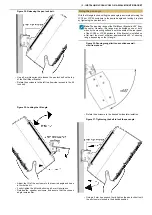

Disassembling the bracket

The Wall Mount Bracket ships fully assembled, but to facilitate

installation, it should first be separated into two parts, the bracket itself

and the wall-mount plate. Before disassembly, be sure to note the proper

interlocking configuration of the tilt mechanism; this will remove doubts

when it is time to reassemble the bracket.

Figure 5. Loosening the tilt lock.

•

Make sure that the tilt mechanism can move freely. If it does not,

use a 5 mm hex wrench to loosen slightly the horizontal hex-

head bolt near the top of the tilt/pan mechanism. The bracket

should be free to tilt, but this bolt should remain in place.