Assembly Instructions Beta Prusa Standard & Deluxe

01/07/14

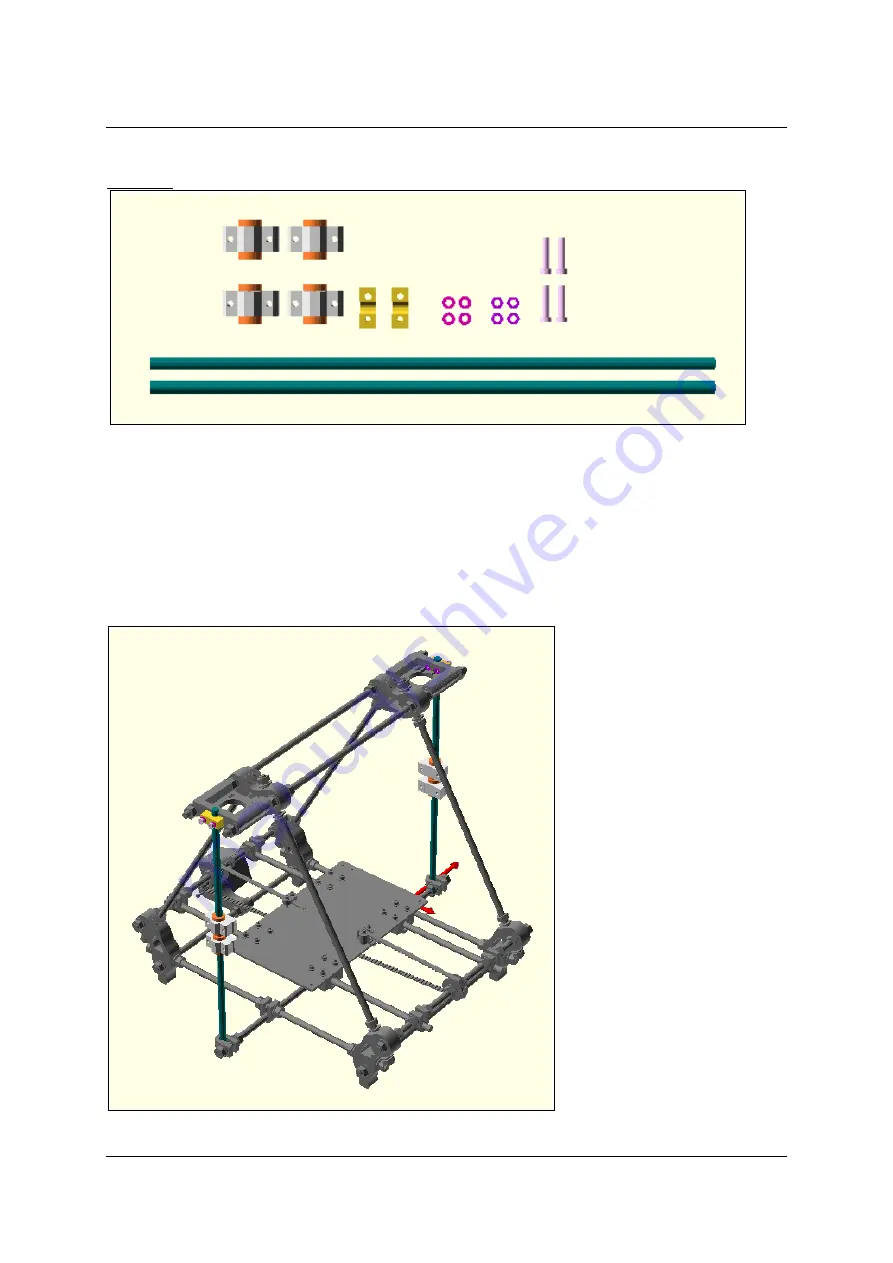

Step 2.3

Needed parts for step 2.3

The following parts are needed for this step:

4x Linear bearings SC8VUU

2x Rod clamps

4x Washer M4

4x Nut M4

4x Screw M4 x 16 mm

2x Smooth rod 8mm x 350 mm

and the structure from the previous steps

Assembly step 2.3

Page 24/ 67