| 1" Metal Blinds Deluxe

5

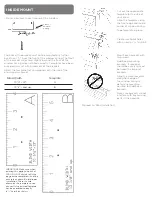

NOTE: Blinds UNDER 60" wide require two screws per

bracket. Screws should be mounted diagonally from one

another. Blinds OVER 60" wide require four screws per

bracket.

Install the blind per the directions for “Blind Installation”.

OPTIONAL HARDWARE

INSTALLATION

EXTENSION BRACKETS

These are available in two sizes and are used to project the

blind up to 3” from the mounting surface. Extension brackets

are available at an additional charge and are ideal if your blind

must clear an obstruction such as a sliding glass door handle

or window crank. Extension brackets require a flat vertical

mounting surface of at least 1

3

/

4

”.

• Attach each mounting

bracket to an

extension bracket

using the nuts and

bolts provided.

• Mount the extension

bracket to the wall per

the instructions for an

“Outside Mount” on

Page 4, making certain

that all mounting

brackets are level

and project the same

distance from the

mounting surface.

• With the blind lowered to its full length, place the pin of

each hold down bracket into the hole in each end of the

bottom rail.

• Using a pencil, mark the mounting surface through the holes

in the hold down bracket. Make sure the hold down brackets

are level and aligned with each other.

• Raise the blind and screw the hold down brackets into the

mounting surface using the screws provided.

SPACERS

Spacers

(2 spacers per bracket)

HOLD DOWN BRACKETS

Hold down brackets are used primarily on shades being

mounted to doors or in motor homes. (2 per blind) Hold

Down Brackets are available by contacting our Client Care

Team at 800-800-3329. There is a small hole in the center of

the end cap that is covered by a thin plastic cover. Use the

pin of the hold down bracket to push through the center of

the end cap and it will break through the plastic cover.

Available for use on windows with

a projected molding. They are

3

/

8

"

thick and allow the blind to be

mounted flush with the outside

edge of any standard window

molding.

Spacers are available by contacting our Client Care Team at

800-800-3329.

• Mount the hold down to the side or back of the window

frame so that the pin lines up with the front hole in the

ottom rail end cap with the blind fully lowered.

• Lower the shade and flex

the hold down bracket

outward so that the pin

can be inserted into the

hole in the end cap.