Installation Manual

H3C S9500 Series Routing Switches

Appendix A Cable Management

A-1

Appendix A Cable Management

A.1 Correct Use of Labels

Before binding the cables, you should fill in the labels for them correctly and stick them

to the right position on the cables. For details, refer to the description of label usage in

Appendix A Engineering Labels for Cables.

A.2 Cable Management Requirements

z

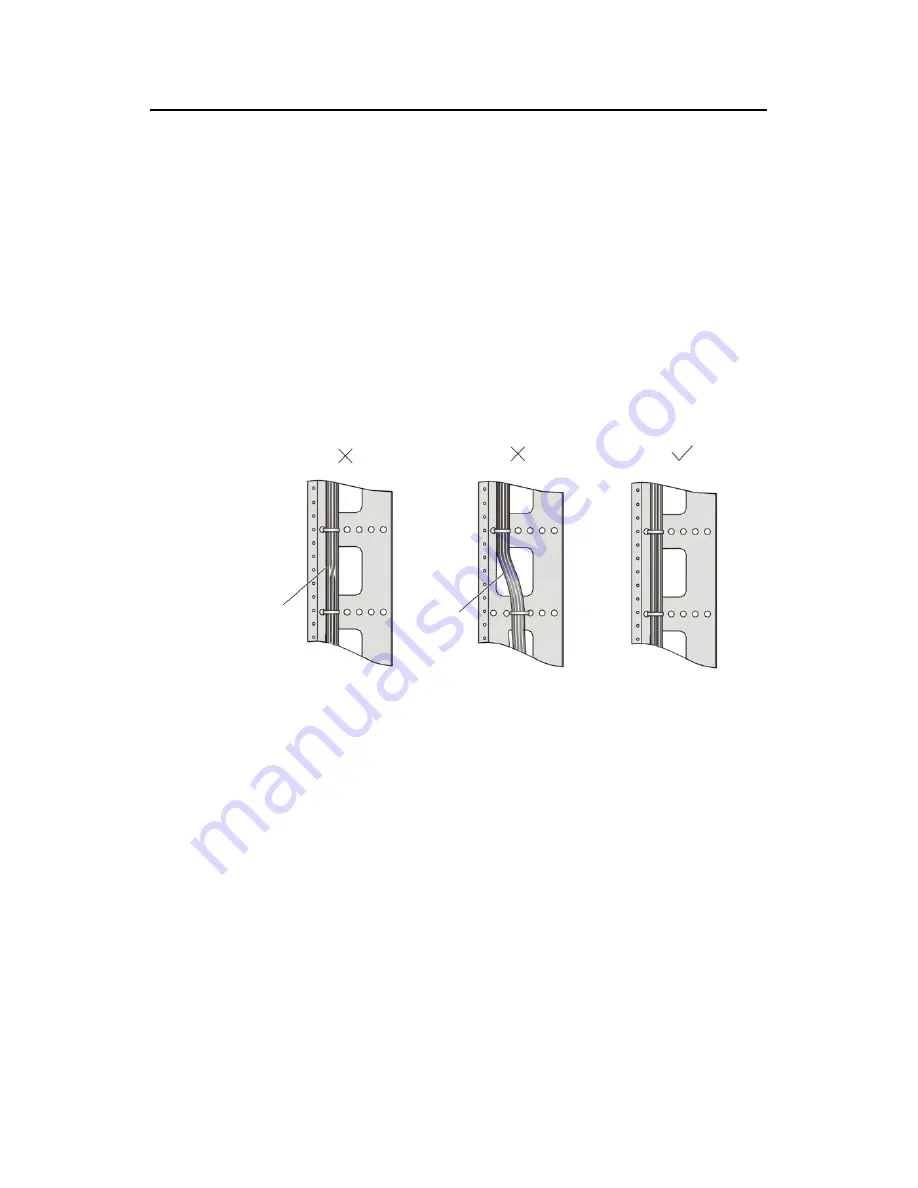

Bind and put the cables inside the cabinet in a straight and neat way. No

intertwinement or bending is allowed.

缠绕

弯曲

缠绕

弯曲

Intertwined

Bent

缠绕

弯曲

缠绕

弯曲

缠绕

弯曲

缠绕

弯曲

Intertwined

Bent

Figure A-1

Cable binding example I

z

The bend radius of cable body cannot be less than twice of the cable diameter.

The bend radius of the cable cannot be less than 5 times of its diameter at the

place where it is led out of the connector;

z

Different cables (power cord, signal cable, PGND wire, etc.) should be cabled and

bound separately rather than together in the cabinet. If they are close to each

other, you can cable them in cross-shape. For parallel cabling, the space between

power cord and signal cable should be no less than 30 mm (1.2 in);

z

The cable binding rack and cabling channel inside and outside the cabinet should

be smooth and without sharp edges or tips;

z

The metal cable management hole should have a smooth and fully rounded

surface or wear a insulating bush;

z

Use the right type of ties to bind the cables. Do not bind cables with joined ties.

The following types of ties are available currently: 100 × 2.5 mm (3.9 in × 0.1 in),

150 × 3.6 mm (5.9 × 0.1 in), 300 ×3.6 mm (11.8 × 0.1 in), 530 × 9 mm (20.9 × 0.4

in), and 580 × 13 mm (22.8 × 0.5 in);