1.

2.

1.

During normal operation of the modeler high temperature are used.

After a mis-build or after long periods of operation, material can be

"cooked" to the surface of the LED.

To clean, remove the board

(see UVLED Board Removal Procedure)

in question and use a razor blade or sharp metal knife to scrape

away (only window glass area) the stuck resin/unnecessary

substances. The glass window is hard enough to use the blade or

metal knife, but be cautious. After removing the substances on the

window, clean the window as described in Step 4- "When there Is

resin or dust on the LED window."

9.5.1 UVLED Board Removal Procedure

9.5.1 UVLED Board Removal Procedure

CAUTION: To prevent personal injury or damage to the modeler, shut down the modeler and disconnect the power before

performing the UVLED Board Removal Procedures. ! Wear protective eye wear and gloves!

Electro-static protection for grounding is required when removing the circuit board to avoid damage to the board. If

you do not feel that this is in your area of expertise, please contact 3D Systems Customer Service for customer

support: US/Canada (800) 793-3669; Central Region, 49-6151-357357

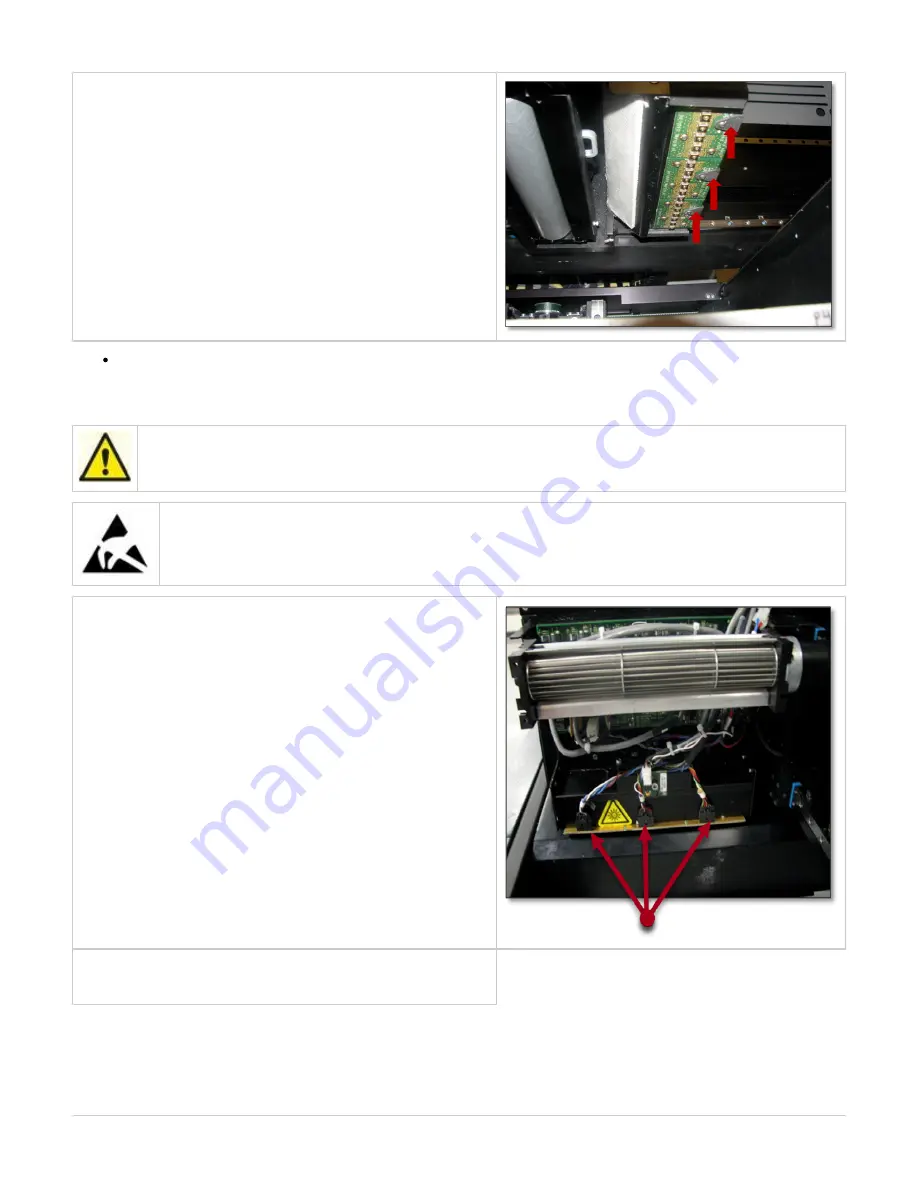

Disconnect the three wire connectors located on the top side of the

three UVLED boards.

NOTE: Before touching the boards UVLEDs, ensure your fingers are

clean of any oily residue. If oily residue contacts the UVLEDs, it may

cause damage to them.

Summary of Contents for ProJet 5000

Page 34: ...This view point button is a back two dimensional viewpoint Bottom View ...

Page 36: ...A bounding box for a set of objects is a cuboid that completely contains the set Copy ...

Page 41: ...This view point button is a front two dimensional viewpoint Help Topics ...

Page 45: ...This view point button is a right two dimensional viewpoint Rotate ...

Page 60: ...Using a wire frame allows visualization of the underlying design structure of a part Zoom ...