MESSAGE

CAUSE

ACTION

HMS ERROR

Recovery

An error occurred during printhead maintenance (cleaning

the printhead before beginning a build).

Cycle power to the modeler. If error message occurs again,

contact your

Hotline.

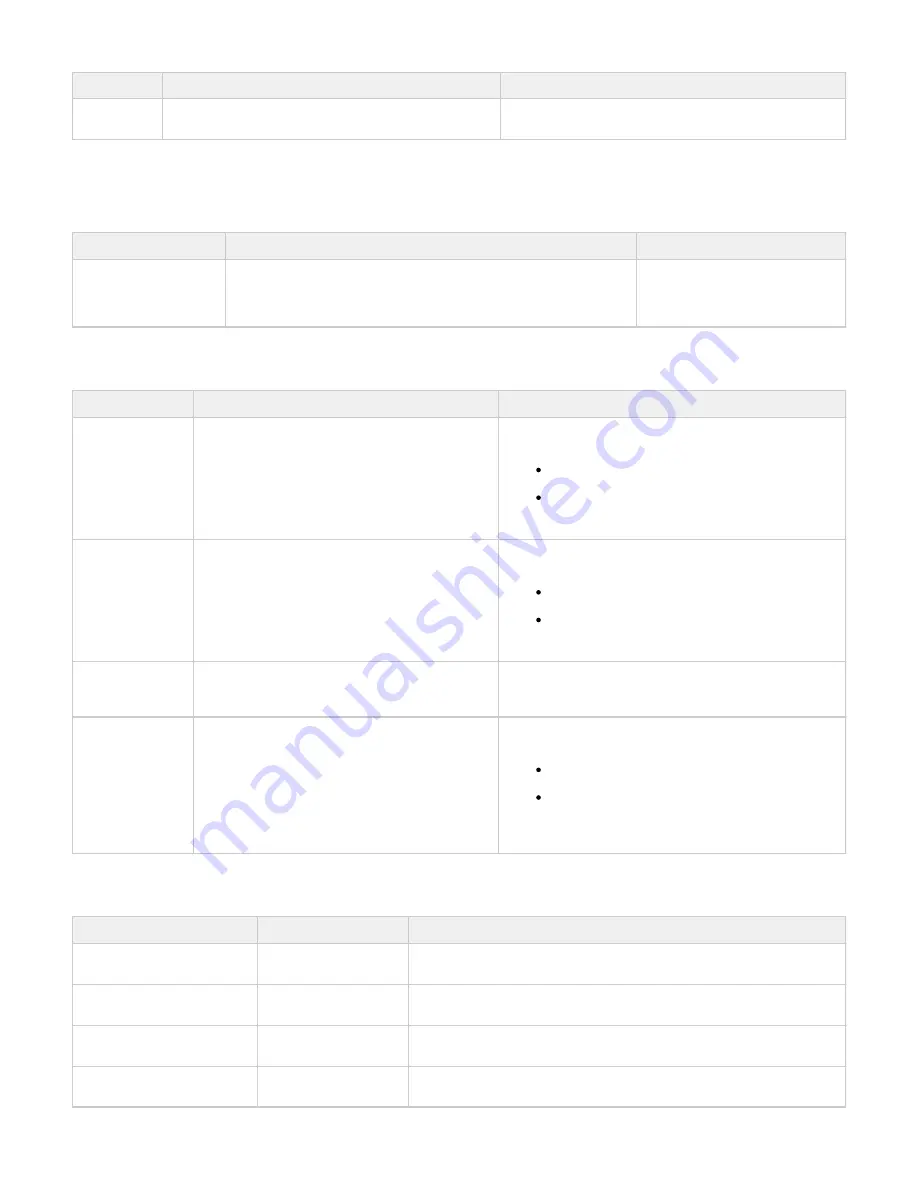

11.3 Material Feed and Waste System Errors

A just loaded cartridge did not engage correctly during the material feed cycle or the printhead sensors did not detect the required material level.

MESSAGE

CAUSE

ACTION

RT_ERROR: material

feed 1 (or 2) can't fill

head

A just loaded bottle did not engage correctly during the material feed cycle

or the printhead sensors did not detect the required material level.

Cycle power to the modeler.

If error message occurs again,

contact your

Hotline.

11.4 Material Quality Guarantee Errors

MESSAGE

CAUSE

ACTION

Support (or build)

material bottles

not detectedd

Modeler is out of material bottles, a bottle misfed, or

the material identification system is faulty.

The build will abort if it needs to use the questionable bottle to

finish the build.

the specified material bottle,

l a clean build

the build job.

If error message occurs again, contact your

Hotline.

Support (or build)

material bottle not

melted

A cold bottle was added to the material delivery system

and it did not have enough time to melt before the

modeler requested material.

The build will abort if it needs to use the questionable bottle to

finish the build.

the build job

after the modeler has reached build temperature.

If error message occurs again, contact your

Hotline.

Support (or build)

material bottle

expired

The material identification system detected expired

material.

Follow the discard instructions posted to the LCD panel.

Support (or build)

material bottle

incorrect type

A material bottle was inserted into the wrong feed slot.

The build will abort if it needs to use the questionable bottle to

finish the build.

Follow the discard instructions posted to the LCD

panel.

If error message occurs again and you have inserted

the correct material bottle into the correct feed slot,

contact your

Hotline.

11.5 Material Waste Errors

MESSAGE

CAUSE

ACTION

RT_ERROR: draintank not

responding

Fault detected in control

circuitry.

Cycle power to the modeler. If error message occurs again, contact your

RT_ERROR: Draintank

Position error

Fault detected in control

circuitry.

Cycle power to the modeler. If error message occurs again, contact your

RT_ERROR: Draintank

timeout error

Fault detected in control

circuitry.

Cycle power to the modeler. If error message occurs again, contact your

RT_ERROR: can't empty

draintank

Sensor or valve

malfunctioned.

Cycle power to the modeler. If error message occurs again, contact your

Summary of Contents for ProJet 5000

Page 34: ...This view point button is a back two dimensional viewpoint Bottom View ...

Page 36: ...A bounding box for a set of objects is a cuboid that completely contains the set Copy ...

Page 41: ...This view point button is a front two dimensional viewpoint Help Topics ...

Page 45: ...This view point button is a right two dimensional viewpoint Rotate ...

Page 60: ...Using a wire frame allows visualization of the underlying design structure of a part Zoom ...