110

3D Systems, Inc

.

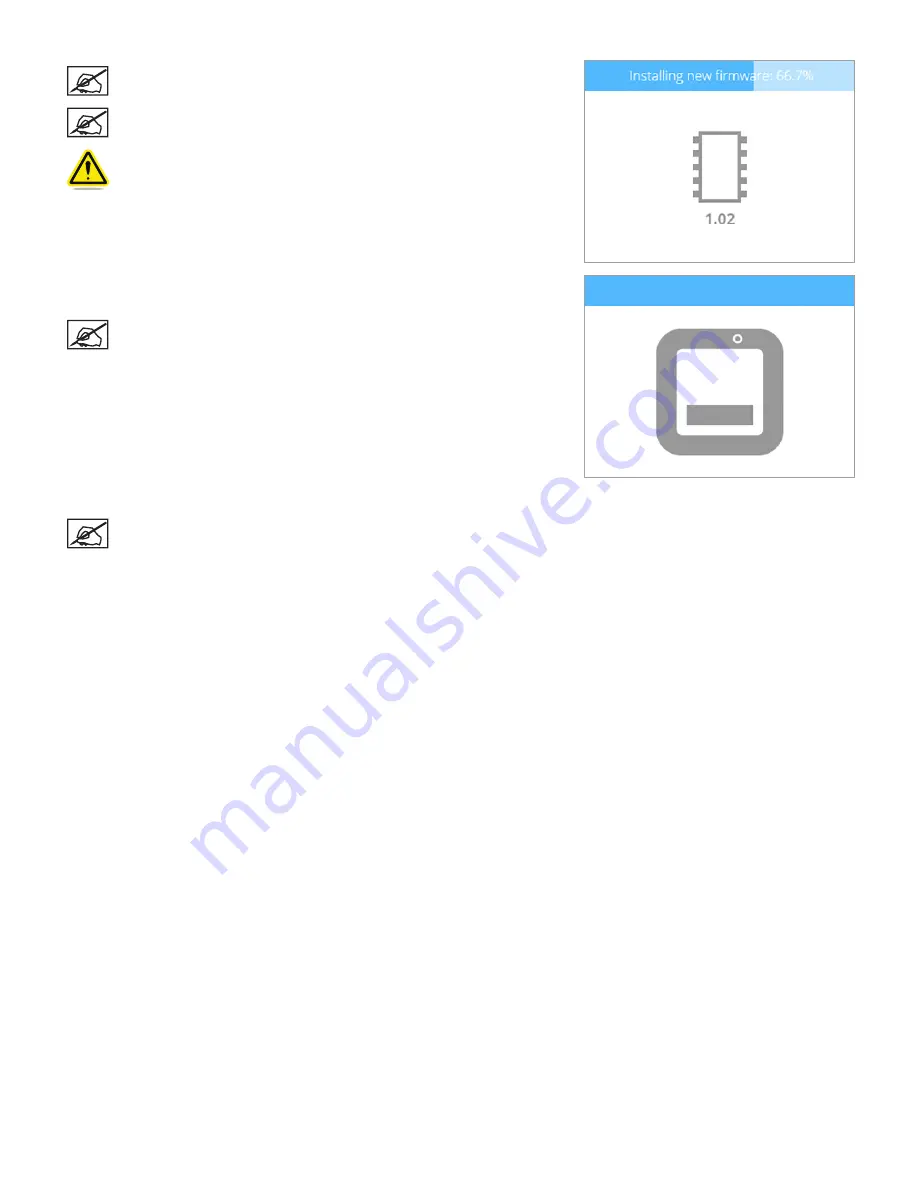

NOTE: The firmware will begin to install. The blue bar is a progress

indicator .

NOTE: The installation could take a few minutes .

WARNING: DO NOT POWER OFF OR DISCONNECT THE PRINTER

FROM UTILITY POWER DURING THE UPDATE PROCESS .

4 . When prompted, press and release the

power button

and wait until the display

turns on .

NOTE: It may take a minute for the display to turn on .

5 . Perform the Auto Level and Auto Gap procedures .

NOTE: For more information, refer to the section titled

Print Pad

Calibration

.

Summary of Contents for CUBE

Page 1: ...Cube Personal 3D Printer User Guide Original Instructions 3rd Generation ...

Page 59: ...55 3D Systems Inc Information Select Information A to view the printer status A ...

Page 72: ...68 3D Systems Inc Change Views Select Change Views and then select the camera viewing angle ...

Page 78: ...74 3D Systems Inc 1 Select an item from My Shelf 2 Select Print Now ...