55

3D Systems, Inc

.

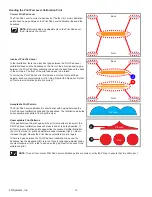

8 . Pull out 12”/30 cm of material from the cartridge . Select the

checkmark

to

continue .

9 . Cut off 2”/5 cm of material from the end . Select the

checkmark

to continue .

NOTE: Ensure the material is not bent or creased . If the material is

not straight, pull out the damaged material from the cartridge . Cut

off and dispose the portion that is damaged .

10 . Insert the material

under the clamp roller

and into the material tube . Select the

checkmark

to continue .

11 . Gently push the material into the print jet until molten plastic extrudes into the jet

wiper . Select the

checkmark

to continue .

NOTE: When the material reaches far enough into the print jet area,

a feed motor will assist with feeding the material into the print jet .