3D Systems, Inc.

18

ProX 500 TRANSFORMER REQUIREMENTS

If the facility does not have 208 VAC, 3-phase, 50/60 Hz, 10 kVA power, a customer-supplied step-up or step-down transformer is

required .

3D Systems stocks the following transformers:

DESCRIPTION

3D SYSTEMS PART NO .

Transformer, 230-250 Volt to 208VAC, 10kVA, 60Hz, 3PH

134005

Transformer, 460-500 Volt to 208VAC, 10kVA, 60Hz, 3PH

134006

Transformer, 385-415 Volt to 208VAC, 10kVA, 50Hz, 3PH (EU Version)

134007

•

If you purchase a transformer from a supplier other than 3D Systems, specify a “wye-to-delta” primary-to-secondary configuration.

•

Connect the transformer secondary neutral to the transformer secondary ground .

Caution: Do not connect the transformer secondary neutral to the printer ground .

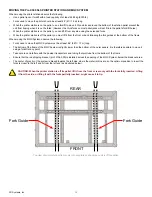

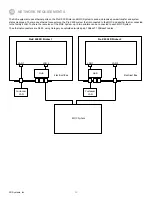

ELECTRICAL REQUIREMENTS

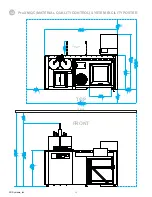

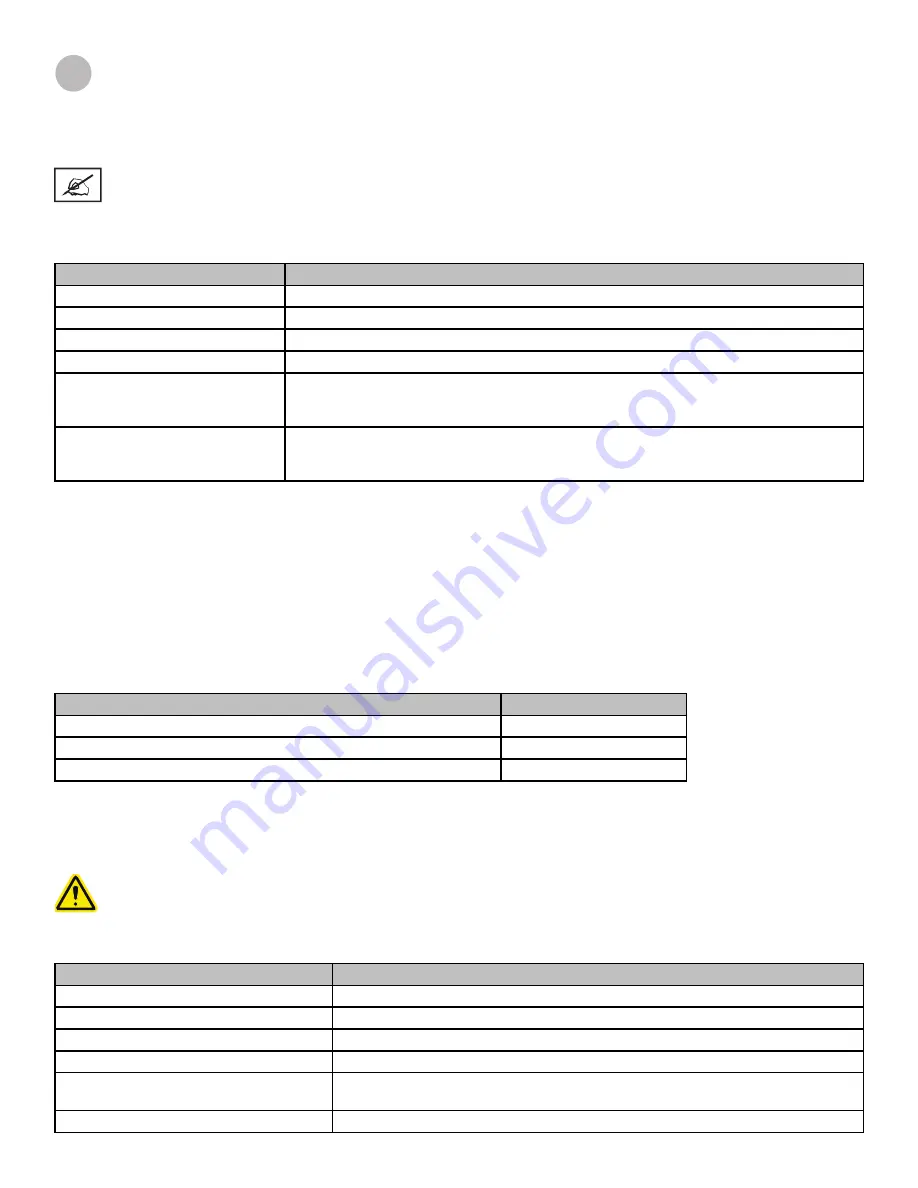

Refer to the

ProX 500 SLS 3D Printer Facility Requirements Poster on page 33

and

ProX MQC (Material Quality Control)

System Facility Requirements Poster on page 32

for visual layouts of the electrical connections . Refer to the

Chiller

Requirements on page 20

for information on the chiller electrical requirements .

NOTE: The ProX 500 is designed to be connected to primary AC power directly from the facility’s power circuit to the

machine’s input power line filter. This task must be performed by a qualified electrician. The facility’s power circuit

must have a 50A branch protective circuit breaker or fused disconnect with lockout/tagout capabilities .

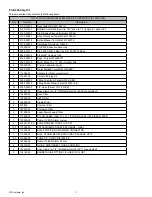

ProX 500 PROCESS STATION POWER REQUIREMENTS

COMPONENT

REQUIREMENTS

Process station input voltage

208 VAC, 10kVA, 50/60 Hz, 3PH

Normal operating current

10 to 21 A

Peak operating current

25 A

On/Off fuse rating

35 A

Power cable (for 3-phase power)

(3 Delta Cond P .E . connection)

Wire size according to local electrical code . Cable drop from ceiling over rear-left side of

process station

Power cable circuit breaker wiring

phase 1 to L1

phase 2 to L2

phase 3 to L3

•

The 3-phase power cable and cable gland (cord grip) are customer-supplied and installed . The cable feeds through the access port

on the top of the printer .

•

Connect the power cable ground wire to the ground bus bar in the printer’s power disconnect box .

•

Connect the printer to a dedicated power circuit .

6

ProX MQC SYSTEM POWER REQUIREMENTS

COMPONENT

REQUIREMENTS

Input voltage (Single Phase)

208-230VAC, 50/60Hz, 1PH

Normal operating current

1 .6 A

Peak operating current

4A

On/Off breaker rating

5A

Power Cable IEC320-C19 Plug

16AWG (ø1 .29mm)

(2 Cond P .E . Connection)

Maximum Room Ambient Temperature

27 °C