3D Systems, Inc.

22

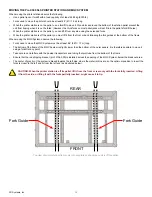

RECEIVING, MOVING, AND STORING THE SYSTEM

This chapter tells you what you will receive in your shipment and how to properly move and unpack the various system components .

Before you move the equipment verify the following:

•

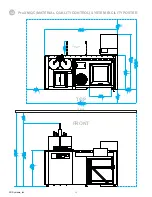

The room is large enough to allow the specified clearance around all sides of the ProX 500 and MQC System. Refer to the

Room

Requirements on page 16

, the

ProX 500 SLS 3D Printer Facility Requirements Poster on page 33

,

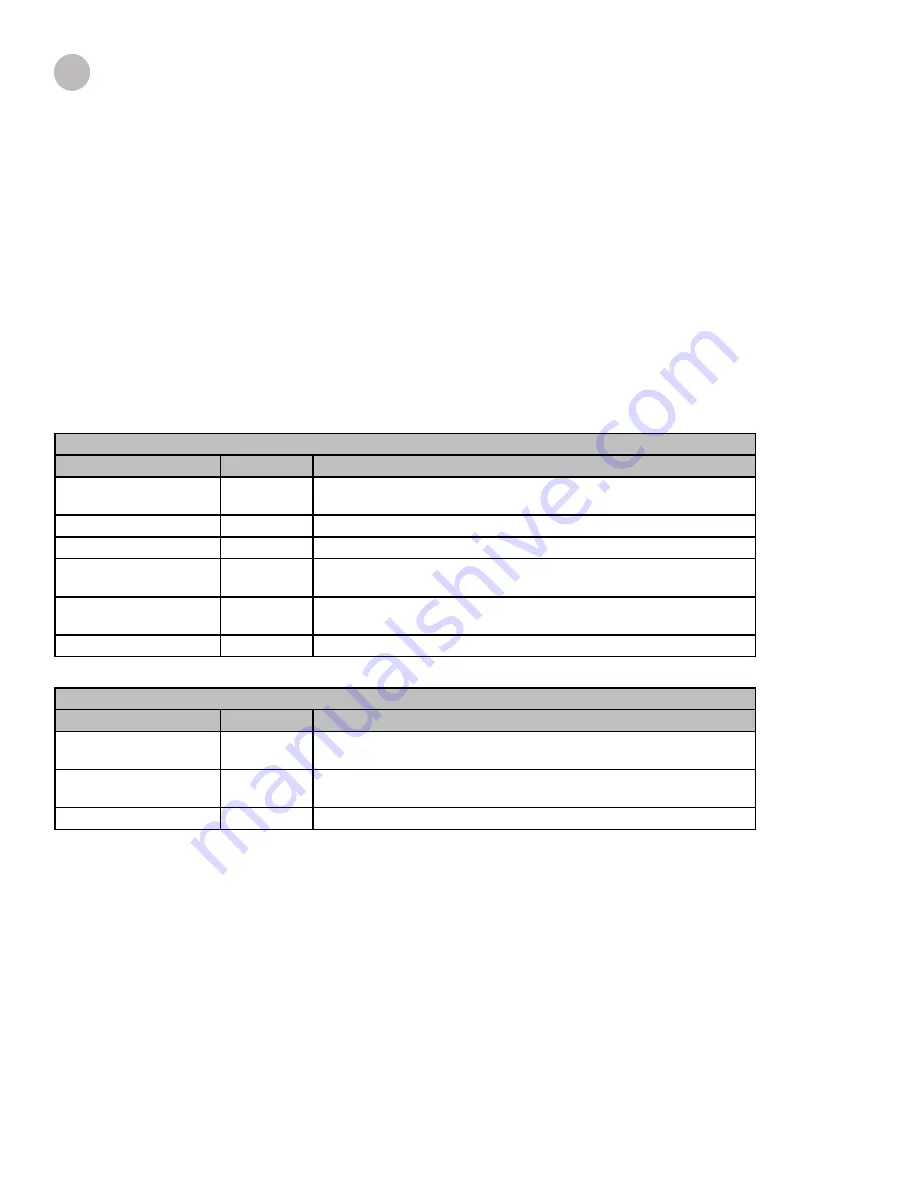

and the

ProX MQC

(Material Quality Control) System Facility Requirements Poster on page 32

for specifications.

•

The floor below ProX 500 SLS Center meets the

Floor Requirements on page 16

.

•

The equipment, including the pallet jack or forklift, will fit through all doorways leading to the installation room as specified in the

“Clearance” sections of the

Room Requirements on page 16

.

9

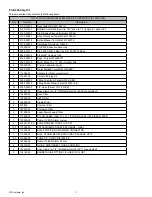

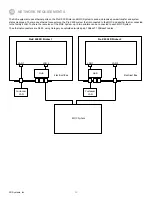

WHAT YOUR SHIPMENT INCLUDES

All possible components of 3D Systems’ ProX 500 SLS 3D Printer system are listed below . They include a ProX 500 SLS 3D Printer

for printing the parts, the system options for material handling, peripheral equipment for part finishing, and items consumed during part

prints such as nitrogen, material, and filters.

Required and Optional System Components

REQUIRED ProX 500 SLS PRINTER COMPONENTS

Component

Supplier

Comment

ProX 500 SLS 3D Printer 3D Systems Requires a 3-phase power source and a separate chiller with its own

single phase power source .

ProX MQC System

3D Systems For part breakout and material handling .

Chiller

3D Systems 3D Systems stocks a recommended chiller and ships it with the system .

Nitrogen supply

3D Systems

or third party

Can use nitrogen tank(s) or a 3D Systems nitrogen generator

depending on consumption/application

Vacuum Cleaner

3D Systems

or third party For cleaning the printer and MQC System between prints .

Accessory Kit

3D Systems Basic tools, equipment .

OPTIONAL ProX 500 SLS PRINTER COMPONENTS

Component

Supplier

Comment

Pneumatic blast cabinet

(“bead blaster”)

3D Systems

or third party

A bead blaster is recommended for DuraForm part finishing . It requires

a 5 .5 bar (80 psi) compressed air source .

Room oxygen monitor

3D Systems

or third party Audible and visible low O

2

alarm .

Anti-static floor mats

Third party

To protect ProX 500 SLS Printer from damaging static discharge