p/n xx-xxxxxx

PROX SLS 6100

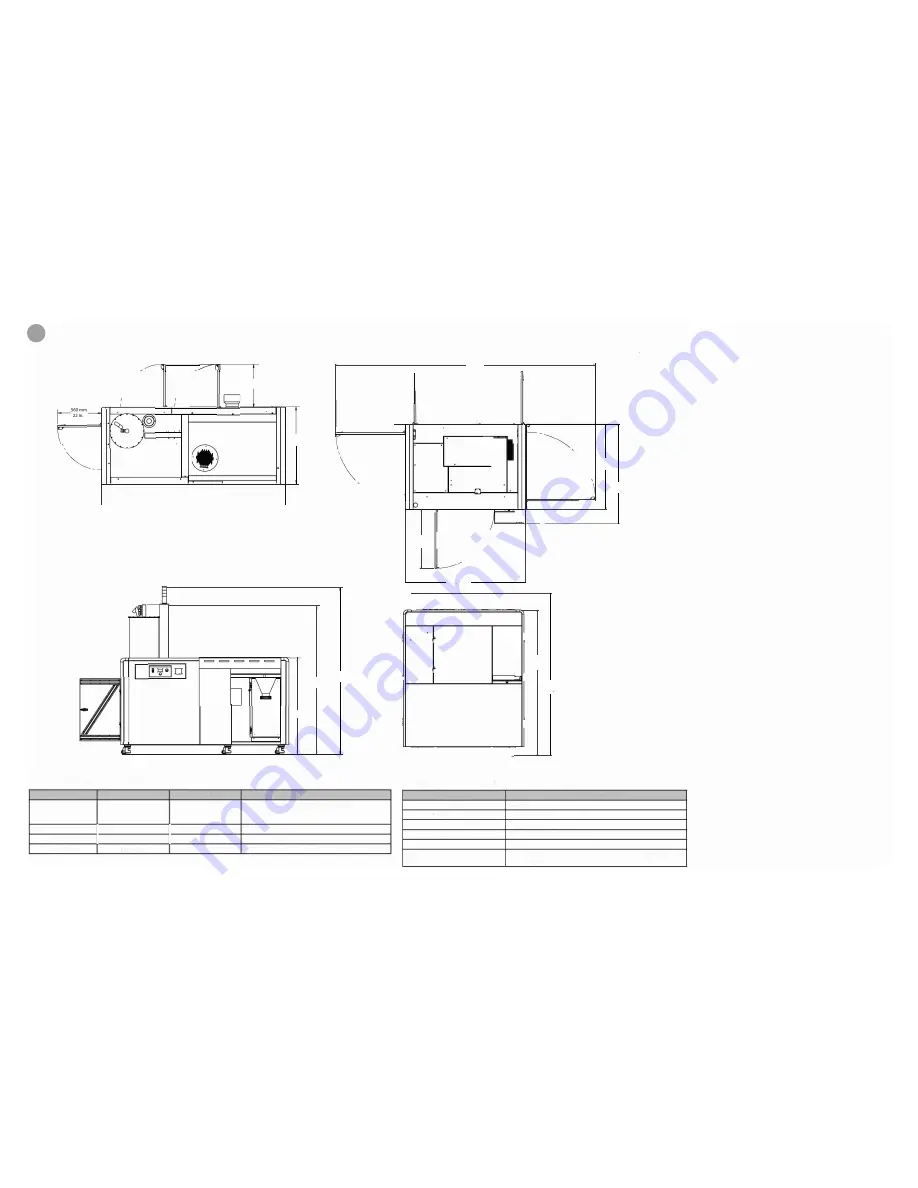

3754 mm

148in.

ATMOSPHERE REQUIREMENTS

(

(

560mm

22 in.

I

n�, /�

779mm

\

(

31 in.

L

·1

i

ATMOSPHERE VARIABLES

REQUIREMENTS

Room temp. controls

Heating & air conditioning installed

A/C not blowing on top of process station

□·

2382 mm

□·

□·

-----------

-------------

94in.

1548mm.

39 in.

1364 mm

54 in.

�

2364 mm

2108 mm

93 in.

83 in.

NOTE: WEIGHT OF SINGLE MQC (497.39 kg/1097 lbs.)

COMPRESSED AIR REQUIREMENTS

COMPRESSED AIR

ProX 6100 3D PRINTER

MQC SYSTEM

3D SYSTEMS N

2

GENERATOR (OPTIONAL)

Industrial inter,change male cou;pliing 1Plug:

Connection Type

1/4" Barbed Hose Fitting 1/4" Barbed Hose Fitting

1/4 intll coupling size, air inlet at top of nitrogen

generator

flow Rate

I

35slpm

I

130 slpm

270 1pm (572 cfh)

Supply Pressure

I

6 bar (90 psi)

1

6 bar (90 psi)

620-690 kPa (90-100 psi)

Qualit

y

CDA (Clean Dry Air)

GOA

CDA

-

.0.

I

�

":'

---

■

---

---

---

---

---

-

---

---

-

·o

Q

-·

•

-

-

-

-

-

-

•

•

-

--

•

CJt

I

I

857mm

/

34 in.

/

1743mm

69

In.

�

�

□

.

rn

D

•

.

::,;.!:

:

c::::::::J '"

�

.

.

!!

\

1222 mm

48 in.

1435

mm

56in

,___ 1005 mm/40 in.

�

� 213m�/ 8in .

i

2109mm

83 in.

i

2353

mm

93in

i

Temperature

Non-condensing

Room air changes

Heat dissipation

Atmospheric corrosives

Operating range: (16 to 32)

°

C; (60 to 90)

°

F

Stability:± 2

°

C (± 5

°

F)

No higher than 70%

4 per hour minimum

Maximum: SkW (17,000 BTU/hr)

Average: 3.2 kW (11,000 BTU/hr)

None; Clean Dry Air (CDA) is required

ELECTRICAL REQUIREMENTS

COMPONENT

Process station input voltage

Normal operating current

Peak operating current

On/Off fuse rating

Power cable (for 3-phase power)

Power cable circuit breaker wiring

REQUIREMENTS

208 VAC, 1 0kVA, 50/60 Hz, 3PH

10 to 21 A

25 A

35 A

(3 Delta Con P.E. connection)

phase 1 to L 1

phase 2 to L2

phase 3 to L3

The 3-phase power cable and cable gland (cord grip) are customer-supplied

and installed. The cable feeds through the access port on the top of the printer.

Connect the power cable ground wire to the ground bus bar in the printer's

power disconnect box.

*Verify with yourlocal building codes that this confoguration meets local requirements .

SLS SINGLE MQC SYSTEM POWER REQUIREMENTS

If the facility does not have 208 VAC, 3-phase, 50/60 Hz, 10 kVA power,

a customer-supplied step-up or step-down transformer is required.

3D Systems stocks the following transformers:

COMPONENT

Input voltage (Single Phase)

Normal operating current

Peak operating current

On/Off breaker rating

Power Cable IEC320-C10 Plug

Max. Room Ambient Temp.

REQUIREMENTS

208-230VAC, 50/60Hz, 1 PH

1.6 A

4A

SA

16AWG (01.29mm)

(2 Con P.E. Connection)

27

°

C

*Verify with yourlocal building codes that this confoguration meets local requirements.

NOTE: WEIGHT OF PROJET SLS 6100 (1469kg / 3239 lbs.)

NITROG E

N

I

SUPPLY REQUIREMENTS

COMPONENT

REQUIREMENT

Purity

99%

Nitrogen line fitting,s

llnlet ¼ inch Barbed Hose F

i

tti

ng

1

Continuous flow

10 slpm (21 scfh) for

l

ength

,

of build

Purgelilow

50 1pm (106 cfh) for 15 minutes

Exhaust

Must exhaust to outside at pressure 0.0025 bar (1.0 in Hp)

Weeldy consumpliion

140 rn3 (4944 ffl) of IN

2

gas based on 24 h/day qperation with

7 1PUrge cycles

15

ProX 6100 SLS 3D PRINTER FACILITY REQUIREMENTS POSTER

Rev_B