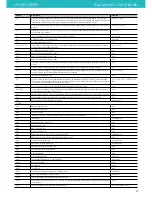

G-Code

Description

Example

G0

Move to the given coordinates. To the contrary of G1, if there is a tool it will most of the time be off during this

kind of move. This is a "go to" move rather than a "do while going to" move. The F parameter defines speed and is

remembered by subsequent commands ( specified in millimetres/minute ) (command is modal)

G0 X10 Y-5 F100

G1

Move to the given coordinates, see above for difference with G0. Takes the same F parameter as G0. (command is

modal)

G1 X20 Y-2.3 F200

G2

Clockwise circular motion : go to point with coordinates XYZ while rotating around point with relative coordinates

IJ (command is not modal)

G2 X10 J5

G3

Counter-clockwise motion : see above (command is not modal)

G3 Y5 X10 I2

G4

Dwell S<seconds> or P<milliseconds>

G4 P1000

G10

Do firmware extruder retract

G10

G10 L2 G10 L20

set workspace coordinates http://linuxcnc.org/docs/html/gcode/coordinates.html and http://linuxcnc.org/docs/

html/gcode/g-code.html#gcode:g10-l2

G10 L2 P1 X0

G11

Do firmware extruder un-retract

G11

G17

Select XYZ plane (command is modal)

G17

G18

Select XZY plane (command is modal)

G18

G19

Select YZX plane (command is modal)

G19

G20

Inch mode : passed coordinates will be considered as Inches, so internally translated to millimeters (command is

modal)

G20

G21

Millimeter mode ( default ) : passed coordinates will be considered as millimeters (command is modal)

G21

G30

Simple Z probe at current XY, reports distance moved down until probe triggers. optional F parameter defines the

speed of probing, zprobe.slow_feedrate is used when not supplied

G30 - G30 F100

G31

Report current Z probe status

G31

G32

Uses Z probe to calibrate delta endstops and arm radius, use R parameter to select only arm radius calibration

and E to select only endstop calibration. I to set target precision, J to set probe_radius, K to keep current endstop

trim settings. In Zgrid module, it starts the grid probing

G32 - G32 R - G32 E - G32 EK - G32

I0.02

G28

Home The given axis, or if no axis specified home all axis at the same time (edge)

G28

G53-G59.3

use workspace coordinates http://linuxcnc.org/docs/html/gcode/coordinates.html and http://linuxcnc.org/docs/

html/gcode/g-code.html#gcode:g54-g59.3

G54

G90

Absolute mode ( default ) : passed coordinates will be considered absolute ( relative to 0.0.0 ) (command is modal)

G90

G91

Relative mode : passed coordinates will be considered relative to the current point (command is modal)

G91

G92

Set current position to specified coordinates

G92 X0 Y0 Z0

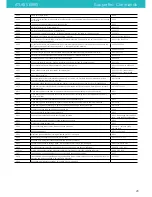

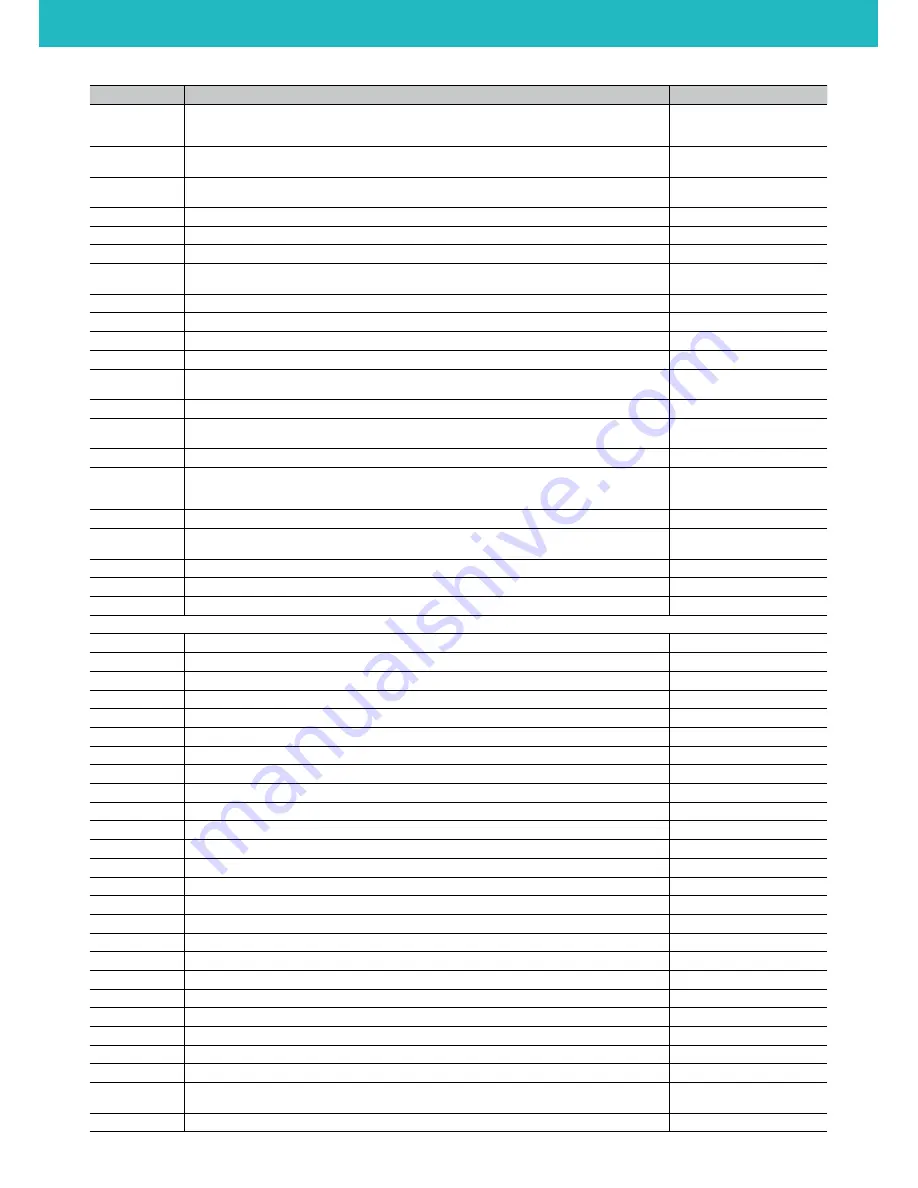

M-Code

M17

Enable stepper motors

M17

M18

Disable stepper motors

M18

M20

List SD card files

M20

M21

Initialize the SD card. This does nothing in Smoothie but is kept for compatibility

M21

M23

Select a file

M23 file.gcode

M24

Start or resume SD card print

M24

M25

Pause SD card print

M25

M26

Abort a SD card print

M26

M27

Report print progress

M27

M28

Begin write to SD card. Use M29 to indicate end of file.

M28 file.gcode

M29

End write to SD card. Used to end file write started with M28.

M29

M30

Delete a file on the SD card

M30 file.gcode

M32

Select a file, and start playing it

M32 file.gcode

M82

Set absolute mode for extruder only

M82

M83

Set relative mode for extruder only

M83

M84

Disable steppers

M84

M92

Set axis steps per mm

M92 E200

M104

Set Extruder Temperature - S<temperature>

M104 S190

M105

Read current temp

M105

M106

Turn fan ON

M106

M107

Turn fan OFF

M107

M109

Set Extruder Temperature and Wait - S<temperature>

M109 S190

M110

Set current line number -N<line number>

M110 N123

M112

Halt all operations, turn off heaters, go into Halt state

M114

Show current position of all axes, XYZ will be the last requested position, whereas ABC is actual current position of

the actuators

M114

M117

Display message on LCD, blank message will clear it

M117 hello world or M117

ATLAS SERIES

Supported Commands

27