PRODUCT DESCRIPTION

3D printing, or additive manufacturing, is a process of making three-dimensional objects of a variety of shapes and sizes from a digital

model. 3D printing is achieved using an additive process, where successive layers of material are heated and melted at the nozzle,

extruded and laid down on the build platform ( also known as Fused Filament Fabrication (FFF). )

The printer is capable of using any material manufactured for FFF type 3D printing, provided the melt temperature and print bed

temperature requirements are within the specifications of the ATLAS outlined in this manual.

The ATLAS is capable of carrying out the additive manufacturing process under open source controls, via 3D model output in the .gcode

format. It can be operated using the USB computer interface or independently with the LCD control unit and SD card.

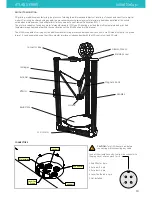

Layer Fan

Z Probe

Extruder 1

Not installed

End Effector

Extruder 0

Layer Fan

Z Probe

Extruder 1

Not installed

End Effector

Extruder 0

CAUTION:

Turn OFF the machine before

connecting or disconnecting any cable.

Look at the orientation notch to align the connector to

the plug, never use too much force.

1. End Effector: 8 pin

2. Extruder 0: 4 pin

3. Extruder 1: 4 pin

4. Layer Fan/Zprobe: 4 pin

5. Not Installed

CONNECTORS

ATLAS SERIES

Initial Setup

Extruder

Effector

Hotend

Carriages

Connector Box

Filament Spool

Build Plate

LCD control

Handles

Magnetic Rods

Endstop cover

10

1

2

3

4