27

Step 6)

Make sure the brakes on the wheels are secured.

Step 7)

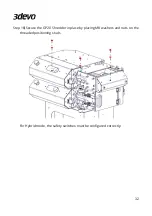

Locate the three mounting holes on the bottom of the

GP20 Granulator

.

The holes should be positioned on the three threaded positioning studs on

top of the

Trolley

Step 8)

Carefully lift the

GP20 Granulator

with two persons on top of the threaded

positioning studs of the

Trolley

.

Summary of Contents for GP20 Hybrid

Page 1: ...GP20 Hybrid Version 2 0 October 2023 English user guide...

Page 13: ...9 2 1 3 GP20 GRANULATOR OVERVIEW 1 Control box 2 Handlebar 3 Toggle clamp 4 Rotary knife...

Page 22: ...18 Step 2 If all the Wheel assemblies are in place tighten the bolts fully...

Page 51: ...47...

Page 58: ...54 Step 3 Carefully pull the scraper comb up and lift it out...

Page 62: ...58...

Page 71: ...67...

Page 82: ...78...

Page 91: ...87 6 NOTES...