13

12

3DISON H700

User Manual V.1

3DISON H700

User Manual V.1

D1. Filament Loading and Unloading

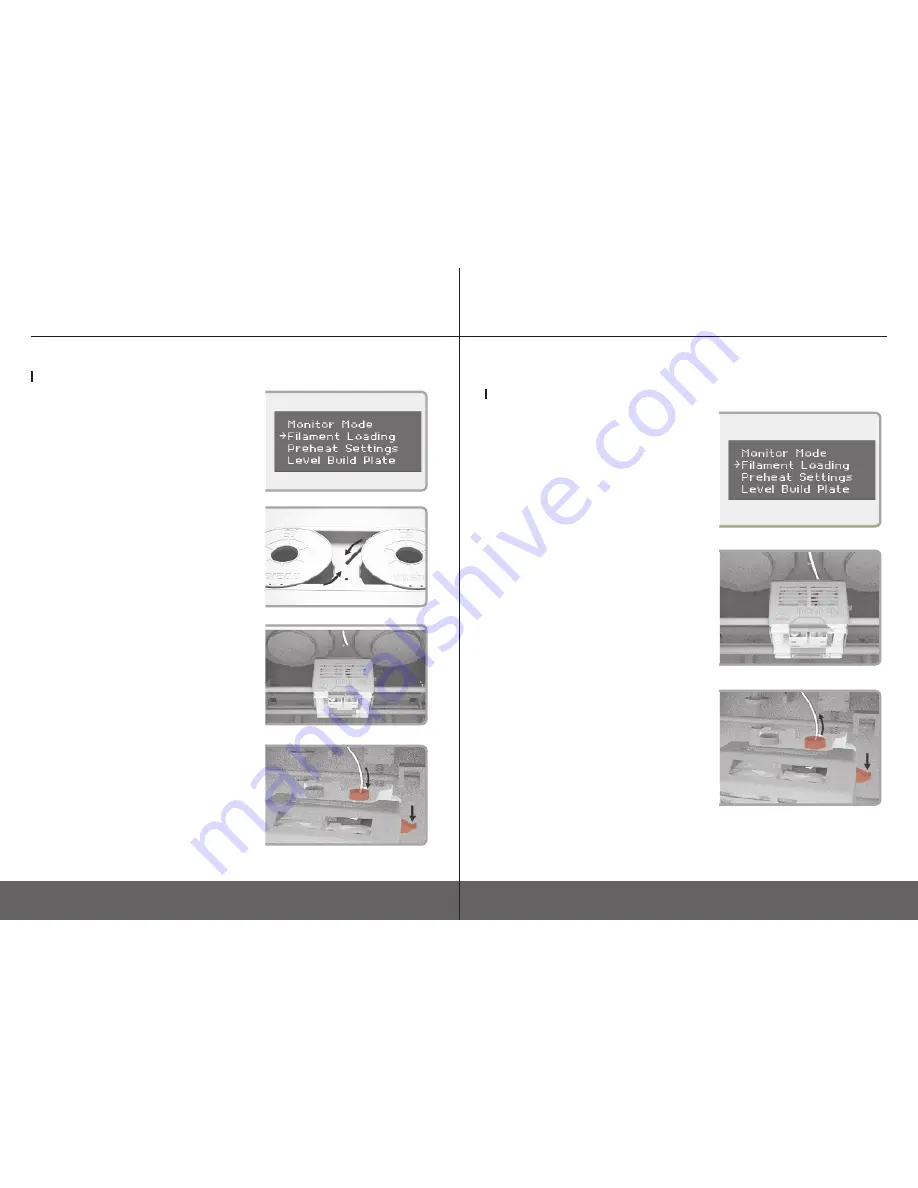

1. Go to the LCD panel and select

Utilities > Fila-

ment Loading.

Select

Load Right

or

Load Left

depending on which side you want to load the

filament. Then the extruder will start preheating.

2. When the extruder is completely heated with

the alarm, put the filament spool into the roof case

and insert the filament into the hole in the middle

of the roof case.

NOTE: Put left filament into the front hole and right

filament into back hole on the roof case.

3. After opening the front door, check to see if the

inserted filament is in, then locate the extruder to

the middle.

4. Push the filament into the blue cap on the extruder

by pressing the spring block until you feel the motor

pulling in it. Wait until you see the filament coming

out from the extruder nozzle.

NOTE: Please make sure to keep the end of

curved filament straight before inserting.

5. Press

OK

button to stop loading.

When loading

D. Getting started:

Filament Loading and Leveling the Printing Bed

D1. Filament Loading and Unloading (Continued)

1. To remove the filament from the extruder, select

Utilities>Filament Loading

and select

Unload

Right

or

Unload Left

depending on which side

you want to remove the filament.

2. When the extruder is completely heated with an

alarm, locate the extruder to the middle.

3. Pull the filament out of the extruder with the

spring block pressed.

4. Press the

OK

button to stop unloading.

When Unloading

D. Getting started:

Filament Loading and Leveling the Printing Bed