3M 3x4 in. OS

2

Revision 022508

CAUTION!

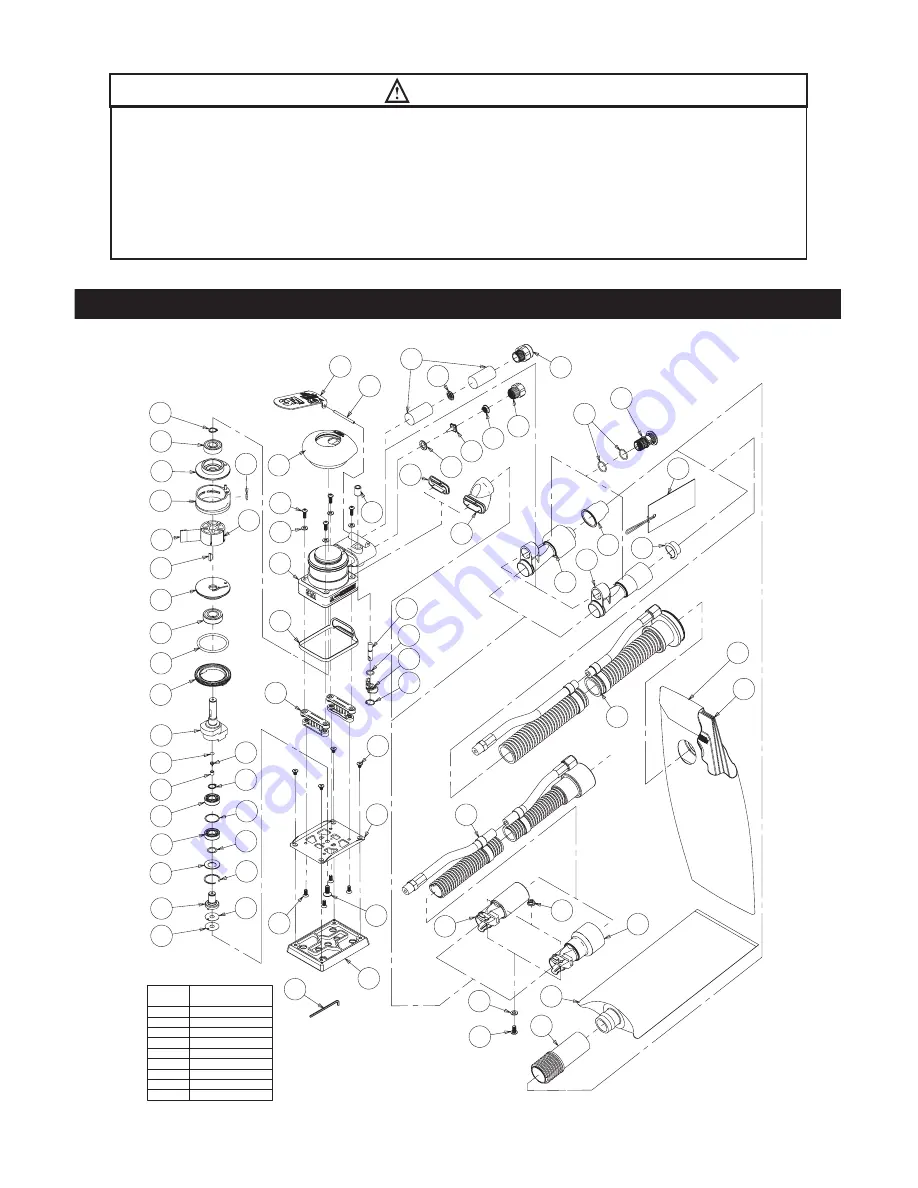

Parts Page

ITEM

TORQUE SETTING

Nm (in.-lbs.)

12

6.2 - 7.3 (55 - 65)

31

2.2 - 2.8 (20 - 25)

40

2.8 - 3.4 (25 - 30)

42

2.8 - 3.4 (25 - 30)

43

10.7 - 11.8 (95 - 105)

48

1.8 - 2.3 (16 - 20)

52

6.8 - 8.1 (60 -72)

56

4.0 - 5.4 (36 - 48)

68

3.4 - 3.9 (30 - 35)

1

2

3

4

7

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

27

28

29

30

31

32

33

34

39

40

41

42

43

44

35

36

37

38

46

47

48

52

51

50

49

53

54

55

56

57

58

59

61

60

62

63

69

66

65

64

67

68

45

25

26

TO

INLET

TO

INLET

TO VACUUM

SYSTEM FOR

CENTRAL VAC

70

71

72

To reduce the risk associated with pneumatic pressure and other mechanical hazards:

• Keep hands, hair and clothing away from the working end of the tool.

• Do not touch the rotating parts during operation for any reason.

• Replace backup pad at normal intervals according to instructions.

• Never operate this tool without all guards or safety features in place and in proper working order.

• Be aware that incorrectly installed hoses and fittings might unexpectedly come loose at any time and create a whipping/impact hazard.

• If you notice any abnormal noise or vibration when operating the product, immediately discontinue its use and inspect for worn

or damaged backup pad. Replace any damaged parts. If abnormal noise or vibration still exists return to the manufacturer for

service or repair. Refer to warranty instructions.