3M 3x4 in. OS

5

Revision 022508

Description

Part

Number

75 x 00 mm (3 x in.) Hookit™ Pad non-vacuum

2033

75 x 00 mm (3 x in.) Hookit™ Clean Sanding

Pad vacuum

2035

75 x 00 mm (3 x in.) Hookit™ Dust Free Pad

vacuum Europe

2022

3M™ Back-Up Pads

3M back-up pads are perfectly mated for use on the 3M Sander.

Constructed from premium, industrial-quality materials with molded

urethane. Their durability and precise construction are the ideal

complement to the performance of the 3M Sander. See Product

Configuration/Specifications table for the correct replacement pad

for a particular model. The following chart is a sample of products

offered.

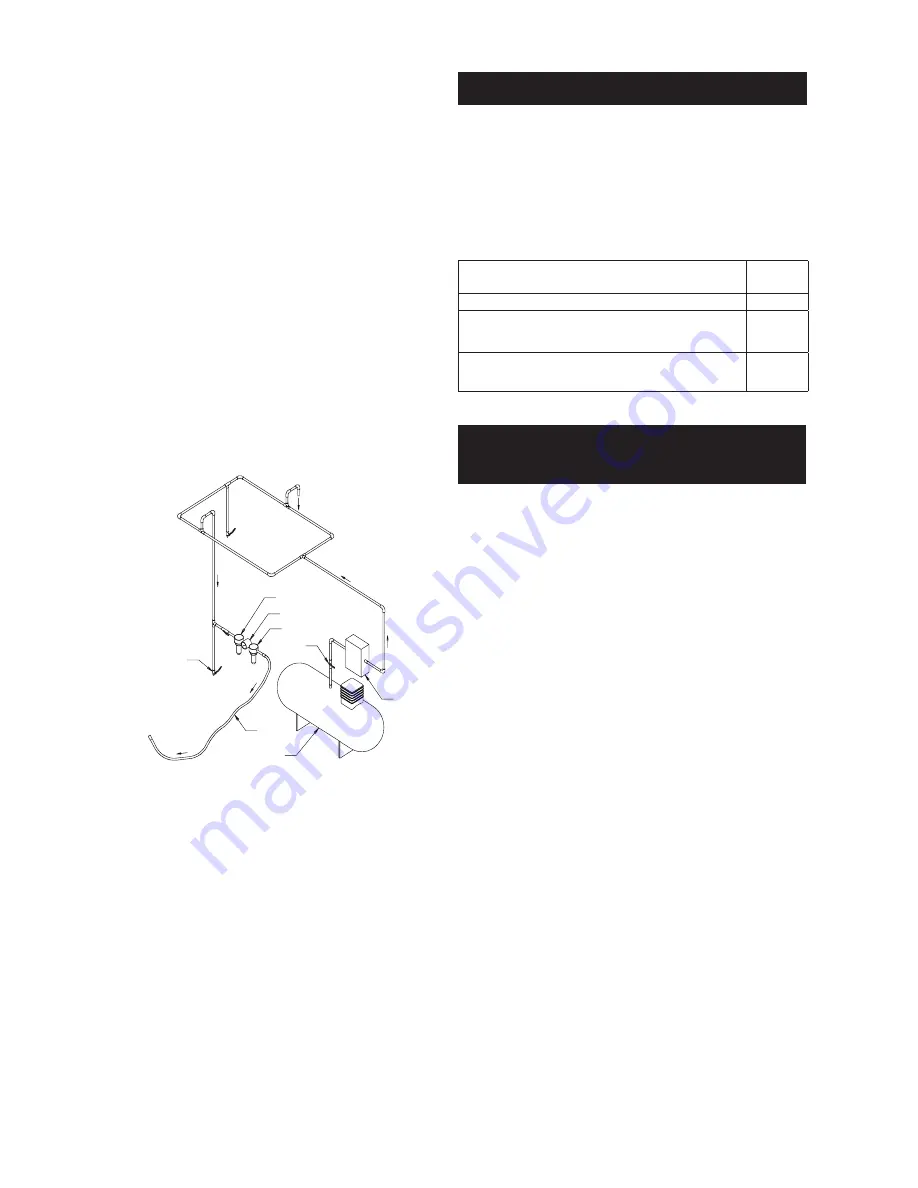

Figure

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool

Removing and Mounting Back-up

Pad to Orbital Sander

. Disconnect air line from sander.

2. Remove old back-up pad from sander by removing the screws

with the wrench supplied with the tool.

3. Position the new backup pad to align the screws with the

threaded holes and tighten securely.

9. Check hose and fittings regularly for wear. Do not carry

the tool by its hose; always be careful to prevent the tool

from being started when carrying the tool with the air

supply connected.

0. Dust can be highly combustible. Vacuum dust collection

bag should be cleaned or replaced as needed. Cleaning

or replacing of bag also assures optimum performance.

. Do not exceed maximum recommended air pressure.

Use safety equipment as recommended.

2. The tool is not electrically insulated. Do not use where

there is a possibility of contact with live electricity, gas

pipes and/or water pipes.

3. This tool is not protected against hazards inherent in

grinding and cutting operations, and no such acces-

sories should ever be attached.

. Take care to avoid entanglement with the moving parts

of the tool with clothing, ties, hair, cleaning rags or loose

hanging objects. If entangled, stop air supply immedi-

ately to avoid contact with moving tool parts.

5. If the tool appears to malfunction remove from use

immediately and arrange for service and repair.

6. Immediately release the start handle in the event of any

disruption of pressure; do not attempt to re-start until the

disruption has been corrected.