17

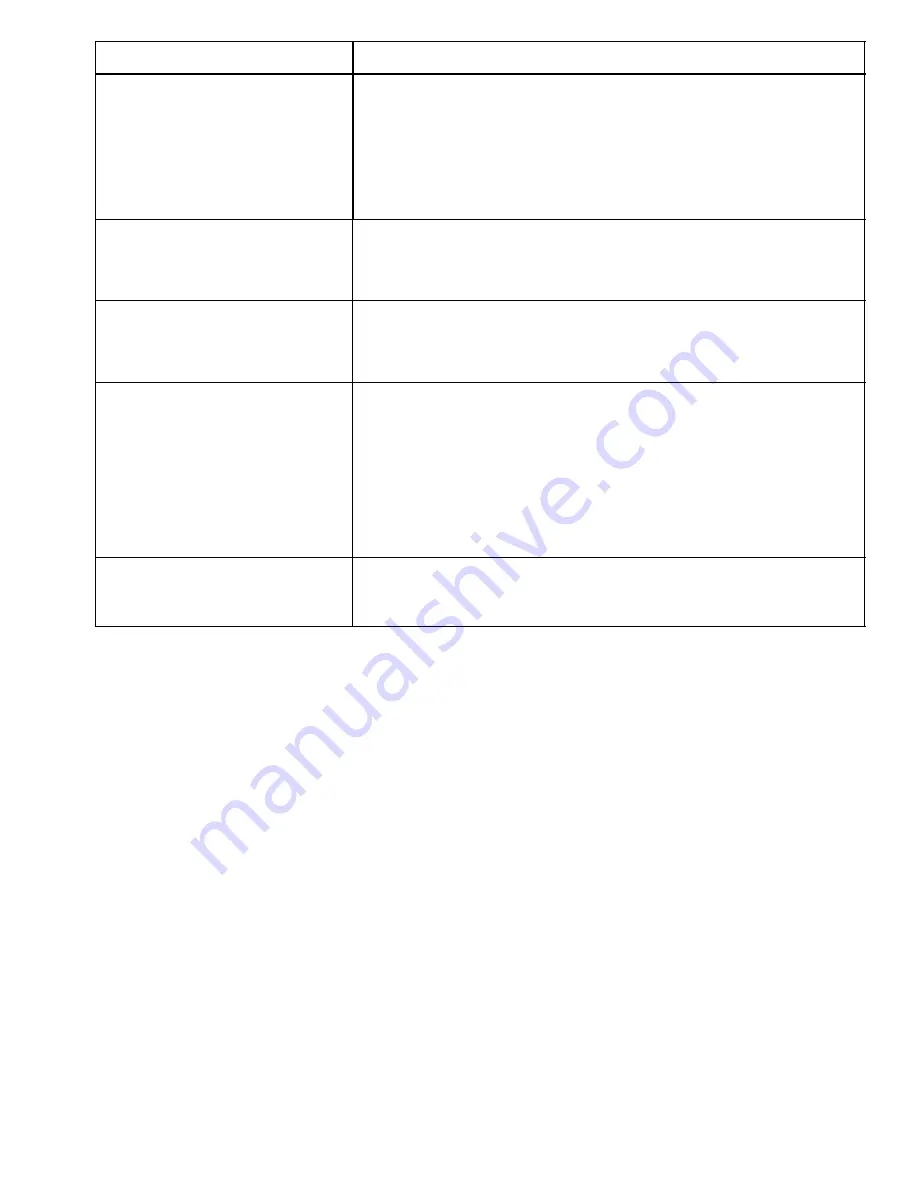

PROBLEM

SOLUTION

Starving Fan Pattern.

Fan pattern begins to narrow down.

PPS liner bottomed out on top of strainer or collapsed around strainer, block-

ing flow (Disconnect air, with PPS cup below gun, pull trigger to re–open liner,

re–connect air and spray mix without purging air from liner).

PPS 200–micron strainer too fine for mix (Use PPS 300 micron strainer or thin/

reduce mix).

Air supply pressure drops due to air supply defects such as other air tools be-

ing used draws down system pressure & CFM flow.

Will not spray.

Not enough flow/air pressure at gun (Check air supply source and hose).

Fluid needle not open enough (Open fluid needle more).

Mix is too thick for fluid tip size (Change to larger size).

Fluid leaking/dripping from PPS

cup.

PPS cup lid loose (Tighten PPS Locking Collar).

Crack in PPS Lid or Liner (Replace).

PPS lid spout not fully engaged with PPS Adapter.

Fluid leaking/dripping from gun.

Check for missing or damaged O–ring (34) at base of Fluid Nozzle on the

Fluid/Adapter Housing

Fluid needle packing nut too tight or binding (Loosen nut or lubricate

needle shaft).

Needle tip damaged (Replace).

Fluid Nozzle nicked or damaged (Replace).

Mix residue dried in gun (Clean & Lube gun).

Excessive overspray.

Too much air pressure (Reduce air pressure).

Gun too far from work surface (Move in and keep the fan pattern perpen-

dicular to the surface to be sprayed).