19

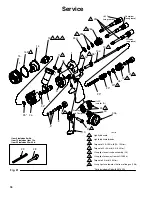

Service

Replacing the air and fluid packings

with gun rebuild kit 16230

Tools Needed:

Wrench 5/16 in. (8 mm)

Wrench 3/4 in. (19 mm)

Gun Tool (28) supplied with gun

Packing Installation Tool (29)

supplied with gun

Mechanics O–ring pick

Needle nose plier

Gun Lube Part No. 16232

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of a serious injury, follow the

Pressure Relief Procedure

on page 11 whenever

you are instructed to relieve pressure.

NOTE:

Gun Repair Kit 16230 comes complete with all air

and fluid seals required to rebuild the spray gun.

Clean parts with a solvent that is compatible with

the parts and the fluid being sprayed.

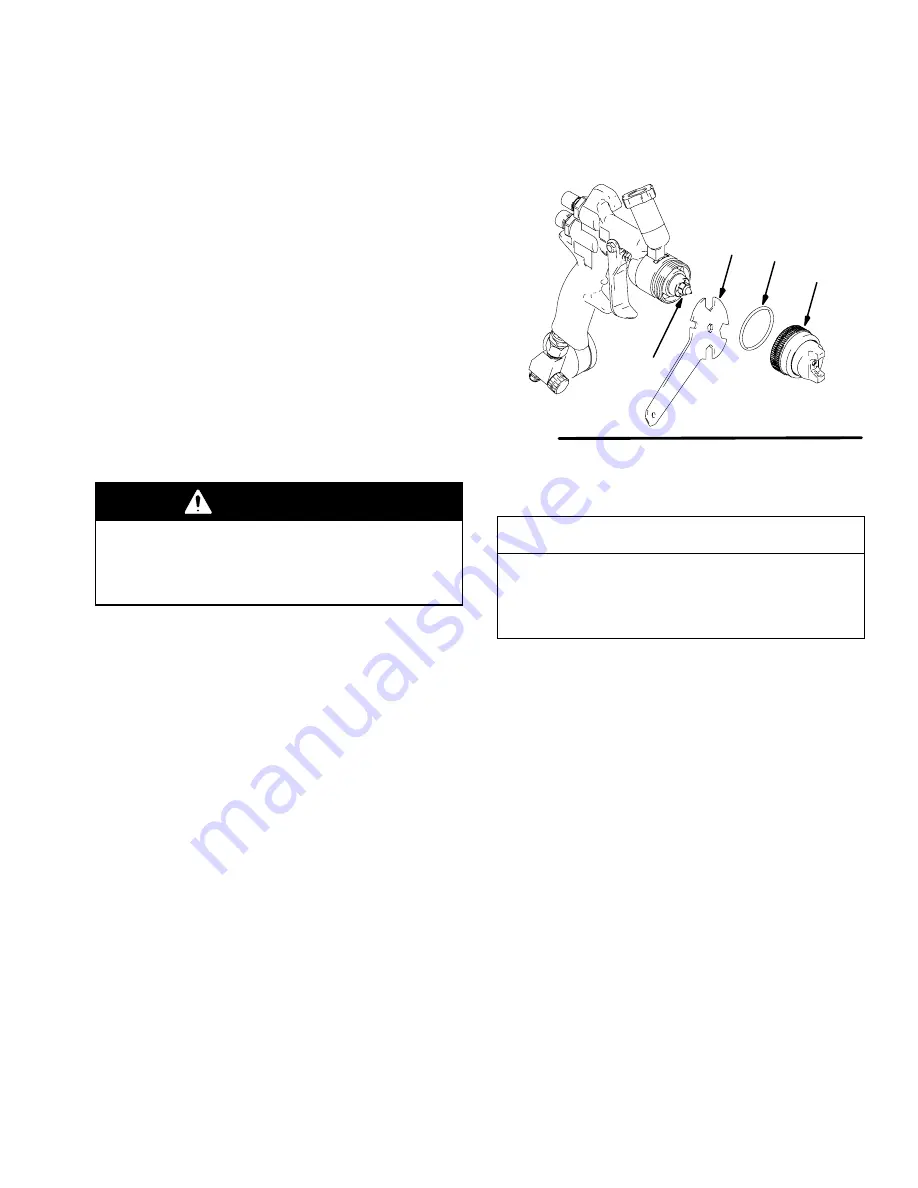

Lightly lubricate the parts indicated in Fig. 21 with

lubricant 16232. This item is not included with gun.

Disassembling the gun

1.

Relieve the pressure.

2.

Flush the spray gun, page 6.

3.

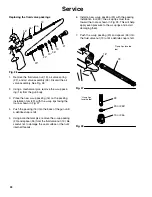

Remove the air cap retaining ring (15) and air cap

(14). Remove and replace the seal (15B). The

U–cup lips must face towards the air cap. See Fig.

22.

Fig. 22

12

15B

28

TI3616C

14, 15

4.

Trigger the gun while you remove the fluid nozzle

(12) with the gun tool (28).

CAUTION

Trigger the gun whenever you tighten or remove the

nozzle. This keeps the needle seat away from the

nozzle seating surface and prevents the seat from

being scratched.

5.

Remove the fluid adjustment knob (21) and fluid

spring (23). See Fig. 21, page 18.

6.

Pull the fluid needle (13) out the back of the gun.

7.

Remove the screw (11), pin (17), wave washer

(18), and trigger (10).

8.

Remove the hex nut (9) with the gun tool (28).

9.

Remove the spray housing (2a) and adapter (4).