12

7.06 When using steel reinforced crossply, and crossply with ribbon

cable, install the 4460-D per practice and twist all reinforcing

members together and bring to one side.

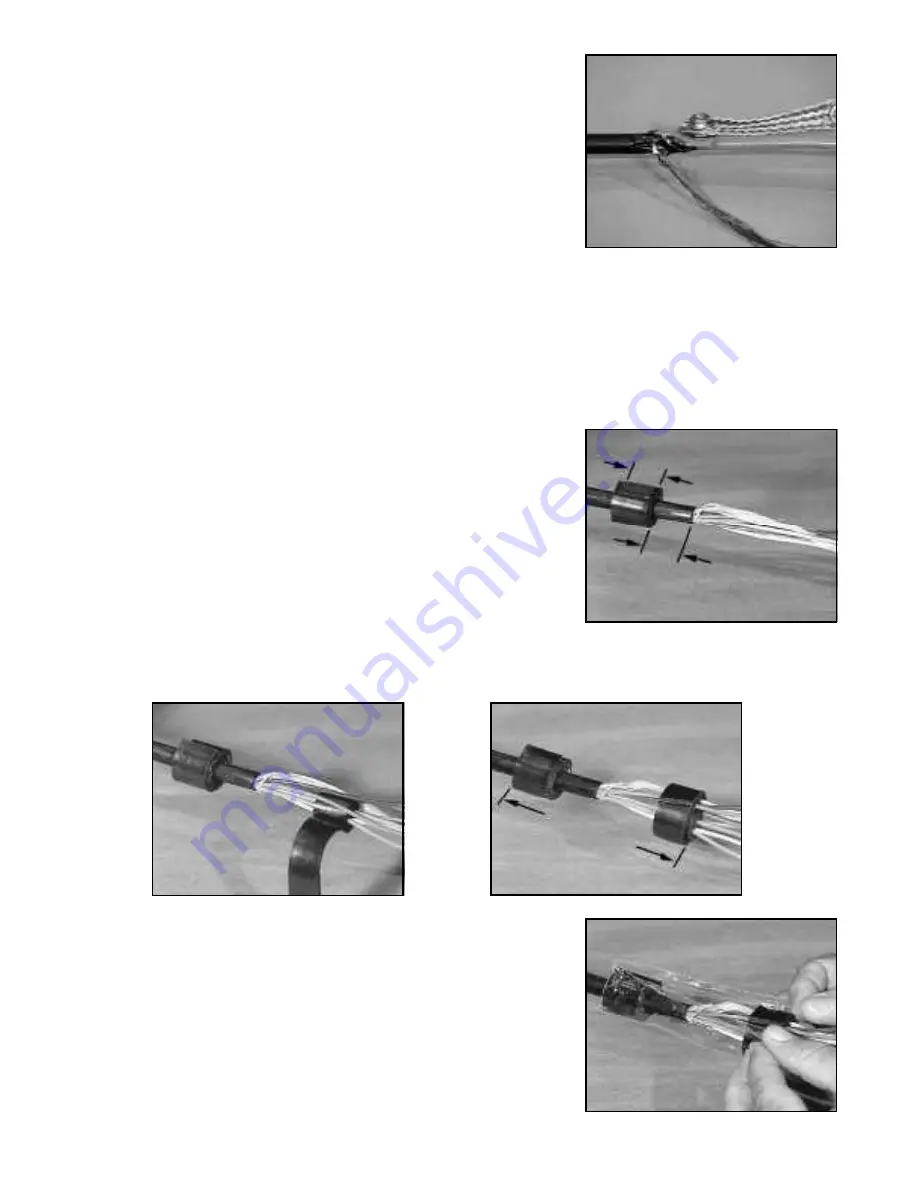

8.04 Lay a 4" (102 mm) long piece of E-Z wrap lengthwise on the

workstation and position between foam collars. Wrap E-Z wrap

edges around foam collars.

8.03 Separate buffer tube(s) and strength members. Build another foam collar by wrapping foam tape between

buffer tube(s) and strength members so the distance between collar outer edges is 4" (102 mm). Wrap two

more layers of foam tape around outside of buffer tube(s).

4" (102 mm)

8.02 Cut two 3/4" (19 mm) wide by 15" (381 mm) long strips of foam

collar tape. Build a foam collar by wrapping at least two layers of

foam collar tape around cable sheath 1" (25 mm) from the end of

sheath.

1" (25 mm)

3/4" (19 mm)

8.0 Core Blocking

Note #1: This core blocking method is used on fiber cable design as of this practice issue date, except

slotted core fiber cable.

Note #2: Core blocking of OFNR cable is not necessary.

Note #3: If sheath has not been scuffed, do before proceeding.

8.01 Non-Armored Application