20

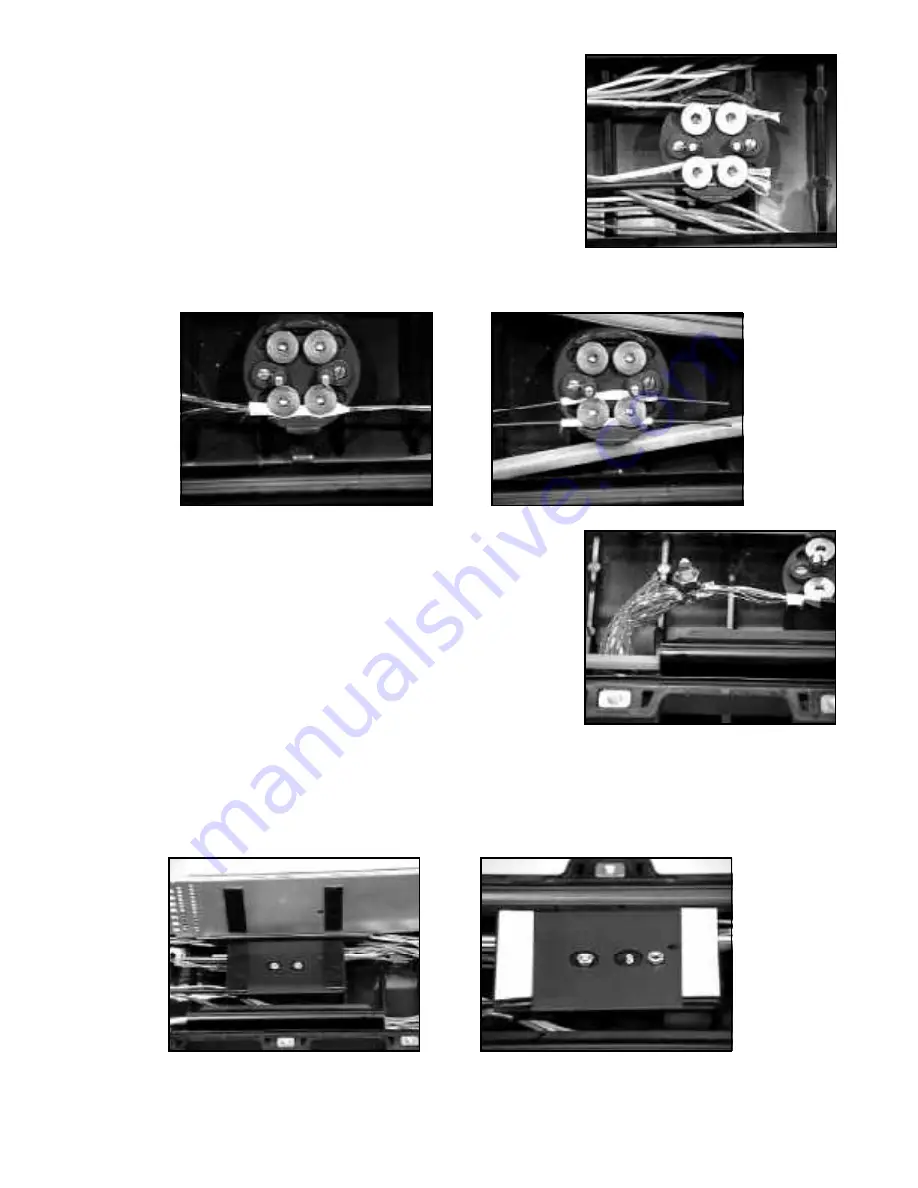

11.05 Cut and position central member under central clamp retention

screws. If necessary, remove insulation from central member.

Using the supplied 7/32" hex key, firmly tighten each retention

screw. If Kevlar is used for cable strain relief, wrap the Kevlar

fibers twice around one central clamp retention screw and

tighten the screw. Cut Kevlar fibers 1/2" (13 mm) from screw.

11.06 The crossply members go under both central clamp retention screws along the outer edge. The LXE

members go under both sides of the two screws. Make sure the taped area is under the screws.

12.0 Universal Organizer Adapter

12.01 The universal organizer adapter is secured onto the studs located on the central clamp. Trays that will fit on

the organizer adapter are the 3M Fibrlok Tray, AT&T, UC Series, Ditel, Preform, and Siecor. The bottom tray

is secured to the adapter by the adhesive-backed dual-lok pads. Additional trays are added by attaching to

the tray below or by using the supplied rod and wing nut.

AT&T Ribbon Cassette (for tray)

PNUC-RR Splice Organizer

AT&T par #103921961

11.07 A split bolt clamp is required to join the crossply members to a

number six or equivalent bond strap. Wrap vinyl tape over the

split bolt connection to protect against sharp edges or pinch

points. Attach to external ground stud.