3

Parts Page

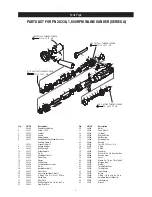

PARTS LIST FOR PN 28338, 1,600 RPM INLINE SANDER (SERIES A)

PARTS LIST FOR PN 28338, 1,600 RPM INLINE SANDER

34870301586 NA

2014July18

Fig. 3M PN

Description

Fig. 3M PN

Description

1

30380

Support Handle Ring

2

30381

Screw, 3/8-16

3

06503

Jam Nut

4

06526

Handle

5

28820

Retaining Ring

6

30377

Double Reduction Sander Gear Case

(Includes Figure 7)

7

06523

Grease Fitting (2)

8

30378

Bearing Retainer

9

30367

Ball Bearing (2)

10

30375

Output Spindle

11

30370

Pin (3)

12

30366

Needle Bearing (3)

13

30431

Planet Gear

14

30379

Spacer

15

30390

Ball Bearing

16

30428

Cantilevered Gear Carrier

17

30370

Pin (3)

18

30366

Needle Bearing (3)

19

30431

Planet Gear

20

30429

Gear Case (Includes Figure 7)

21

06609

O-Ring 3/32 in x 1 3/8 x 1 9/16

22

30432

Pinion Gear

23

30427

Wear Plate

24

06506

Ball Bearing 3/8 in x 7/8 in x 9/32 in

25

30433

Front End Plate

26

06640

Rotor

27

06643

Vane, Set of 5

28

06563

Cylinder

29

06560

Rear End Plate

30

06508

Ball Bearing

31

30369

Retaining Ring

32

06638

Housing

33

06558

Torr Pin, 3/16 in x 7/8 in

34

06543

O-Ring

35

06511

O-Ring

36

06556

Regulator

37

06501

Screw, 6-32 x 3/4 in Set Soc Hex

38

06598

Housing Cover

39

06642

Lever

40

06559

Groove Pin, 1/8 in x 7/8 in Type E

41

06566

Warning Label

42

06557

Muffler

43

06552

Throttle Valve Seat

44

06553

Throttle Valve

45

06554

Taper Spring

46

06555

Screen

47

06608

O-Ring, 1/16 in x 5/8 in x 3/4 in

48

06604

Rotatable Exhaust Deflector

49

06605

Inlet Bushing

50

30437

Wrench

42 43

44

45

48

46

49

47

50

32

33

34

35

36

37

38

39

40

41

21 22

23

20

7

16

17

18

19

8

9

10

11

12

13

14

15

1

2

3

4

5

6

24

27

25

26

28

29 30 31

7

USE 3M TL62 THREADLOCKER

TO 20-25 FT -LB

USE 3M TL62 THREADLOCKER

TO 25-30 FT -LB

USE 3M TL62 THREADLOCKER

TO 20-25 FT -LB

USE 3M TL62 THREADLOCKER

TO 15-20 FT -LB

Fig.

3M PN

Description

1

30380

Support Handle Ring

2

30381

Screw, 3/8-16

3

06503

Jam Nut

4 06526 Handle

5

28820

Retaining Ring

6

30377

Double Reduction Sander Gear Case

(Includes Figure 7)

7

06523

Grease Fitting (2)

8

30378

Bearing Retainer

9

30367

Ball Bearing (2)

10

30375

Output Spindle

11

30370

Pin (3)

12

30366

Needle Bearing (3)

13

30431

Planet Gear

14 30379 Spacer

15

30390

Ball Bearing

16

30428

Cantilevered Gear Carrier

17

30370

Pin (3)

18

30366

Needle Bearing (3)

19

30431

Planet Gear

20

30429

Gear Case (Includes Figure 7)

21

06609

O-Ring 3/32 in x 1 3/8 in x 1 9/16 in

22

30432

Pinion Gear

23

30427

Wear Plate

24

06506

Ball Bearing 3/8 in x 7/8 in x 9/32 in

25

30433

Front End Plate

Fig.

3M PN

Description

26 06640 Rotor

27

06643

Vane, Set of 5

28 06563 Cylinder

29

06560

Rear End Plate

30

06508

Ball Bearing

31

30369

Retaining Ring

32 06638 Housing

33

06558

Torr Pin, 3/16 in x 7/8 in

34 06543 O-Ring

35 06511 O-Ring

36 06556 Regulator

37

06501

Screw, 6-32 x 3/4 in Set Soc Hex

38

06598

Housing Cover

39 06642 Lever

40

06559

Groove Pin, 1/8 in x 7/8 in Type E

41

06566

Warning Label

42 06557 Muffler

43

06552

Throttle Valve Seat

44

06553

Throttle Valve

45

06554

Taper Spring

46 06555 Screen

47

06608

O-Ring, 1/16 in x 5/8 in x 3/4 in

48

06604

Rotatable Exhaust Deflector

49

06605

Inlet Bushing

50 30437 Wrench