North American - ENG

Date Released:

05-22-18

3M-Matic

™

Accuglide 4 - 2 and 3 Inch Taping Head - Type 11800

Page 14

44-0009-2146-8 / ECO# 0078045

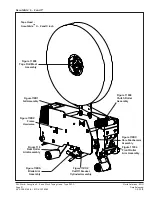

Alignment

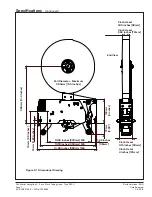

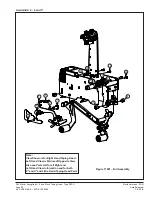

Figure 5-1 Tape Alignment

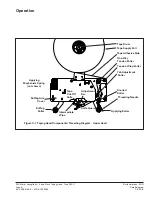

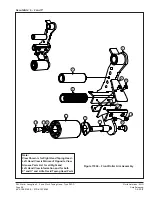

Figure 5-2 Tape Alignment

(adjustments

continued

on next page.)

Adjustments

Tape Alignment and Tracking

–

Figure 5-1

An adjustment system behind the tape roll hub

is provided to center the tape as it

moves along the tape applicator rollers and

onto the case. Adjusting the position of the

hub brake o

ff

sets the tape moving through the

applicator.

To adjust tape tracking, loosen the nut behind

the hub brake. Turn the screw clockwise to

push out the hub brake, or counter-clockwise

to move the hub brake closer to support arm.

Retighten the nut to lock assembly in new

position.

The tape should be applied directly over the

center line of the case

fl

aps and should not

extend past the edge of the rollers

(Figure 5-2).

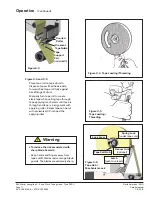

Note:

Only

fi

ne adjustments for tape

alignment should be done on the

tape applicator.

• To reduce the risk associated with shear,

pinch, and entanglement hazards

- Turn air and electrical supplies o

ff

on associated equipment before

performing any adjustments, mainte-

nance, or servicing the taping heads

- Never attempt to work on the taping

head or load tape while the box drive

system is running.

Warning

Adjustment

Nut