24

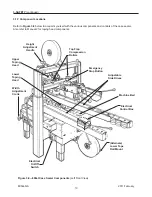

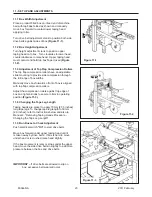

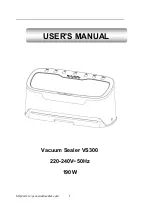

12.1 Operator's Correct Working Position and

Operational Flow (Figure 12-1).

Once the box has been

fi

lled, close its top

fl

aps and

push it between the top and bottom drive belts.

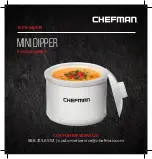

Always keep hands in position as shown in

Figure 12-2.

The box will be automatically sealed with adhesive

tape on the top and bottom box seams. Then the

box will be expelled on the exit conveyor.

12-OPERATION

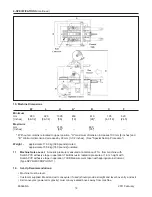

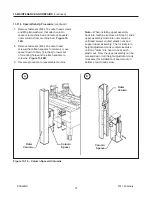

12.3 Starting Production

After having adjusted the machine according to the

box dimensions (height-width), let the machine run

without cartons and check its safety devices. Then

start the working cycle.

12.4 Tape Replacement and Threading

Skill 1 - Operator

See Manual 2: AccuGlide™ 2+ 2 Inch

Taping Heads.

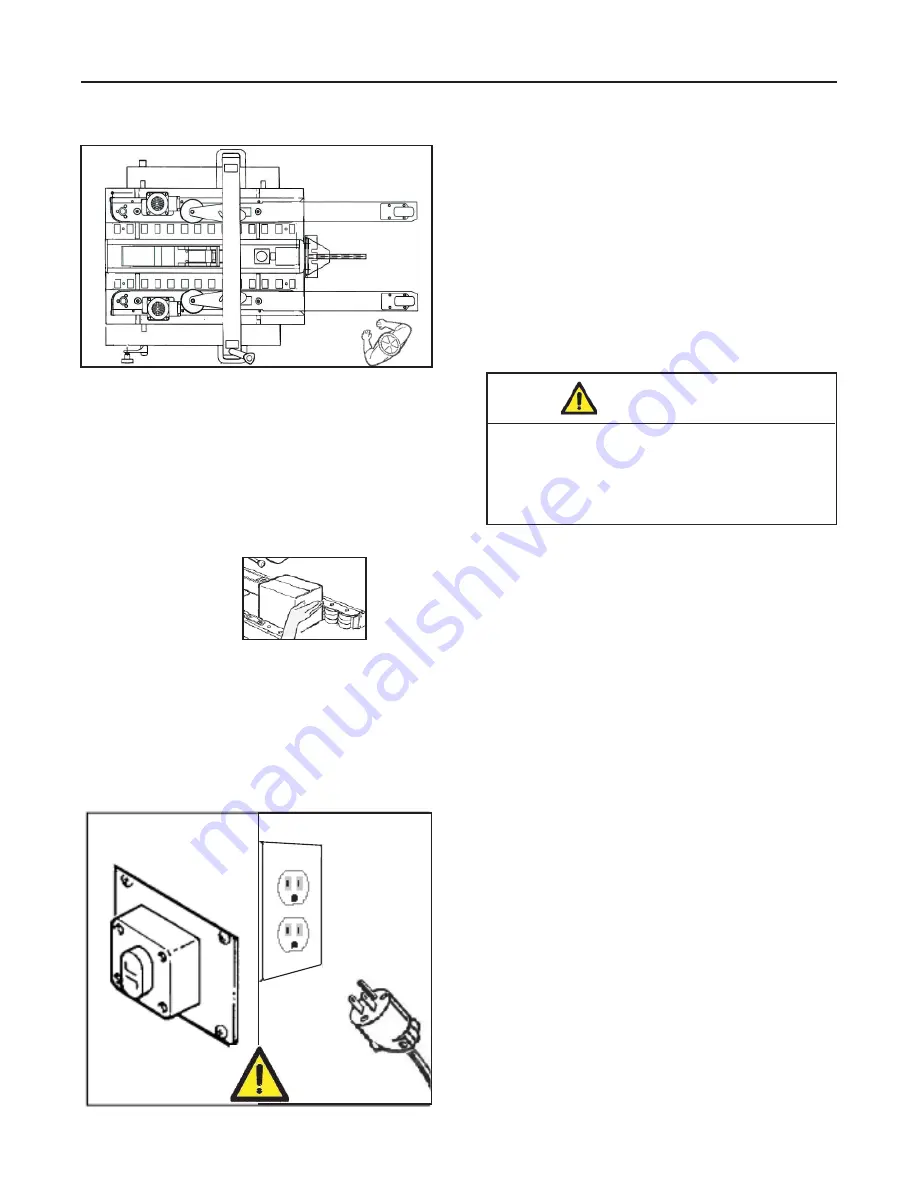

Press the

LATCHING EMERGENCY STOP BUTTON.

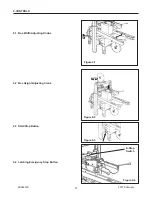

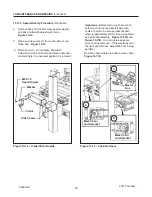

12.5 Box Size Adjustment

Repeat all the operations shown in

Section 11 - Set-Up and Adjustments.

12.6 Cleaning

Before carrying out any cleaning or maintenance

operation stop the machine by Pushing the OFF

switch on the main and disconnect the electric power

(Figure 12-3).

12.8 Safety Devices Inspection

1 Taping units blade guard

2 Latching emergency stop button

3 STOP (OFF) main switch

Operator

Qualifi cations

1 Tape loading and threading

1

2 Tape web alignment

1

3 Adjustment of one way tension roller

1

4 Adjustment to box size (H and W)

1

5 Top

fl

ap compression rollers

1

6 Adjustment of tape applying spring

1

7 Conveyor bed height adjustment

1

8 Special Adjustment-Changing tape leg length 2

9 Special Adjustment-Column re-positioning

2

12.7 Table of Operation Adjustments -

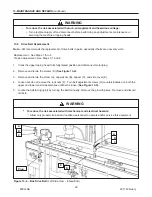

12.2 Starting the Machine

Important:

Before starting the machine, verify that

no tools or other objects are on the conveyor bed.

Push the main switch ON after the EMERGENCY

BUTTON is released

(Figure 12-3).

2011 February

800at-NA

Figure 12-3

Figure 12-1

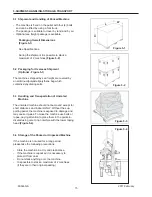

•

To reduce the risk associated with sharp

blade hazards:

−

Keep hands and

fi

ngers away from tape

cutoff blades under orange blade guards.

The blades are extremely sharp.

WARNING

Hand

Position

Figure 12-2

Summary of Contents for 39600

Page 4: ...THIS PAGE IS BLANK ...

Page 6: ...THIS PAGE IS BLANK ...

Page 8: ...8 THIS PAGE IS BLANK ...

Page 10: ...THIS PAGE IS BLANK ...

Page 48: ...36 THIS PAGE IS BLANK ...

Page 50: ...38 THIS PAGE IS BLANK ...

Page 52: ...40 THIS PAGE IS BLANK ...

Page 53: ...41 16 TECHNICAL DIAGRAMS 16 1 Electric Diagram 2011 February 800at NA ...

Page 56: ...44 THIS PAGE IS BLANK ...

Page 58: ...46 2011 February 800at NA 800at Figure 10440 ...

Page 60: ...48 2011 February 800at NA 800at Figure 3269 ...

Page 62: ...50 2011 February 800at NA 800at Figure 5350 1 ...

Page 64: ...52 2011 February 800at NA 800at Figure 5817 ...

Page 66: ...54 2011 February 800at NA 800at Figure 6162 1 ...

Page 68: ...56 2011 February 800at NA 800at Figure 6162 2 OPTIONAL ...

Page 70: ...58 2011 February 800at NA 800at Figure 6163 1 ...

Page 72: ...60 800at 2011 February 800at NA Figure 6163 2 Rear ...

Page 78: ...66 Figure 6165 800at 2011 February 800at NA ...

Page 80: ...Figure 6166 800at 2011 February 800at NA ...

Page 82: ...70 THIS PAGE IS BLANK ...

Page 84: ......

Page 86: ...THIS PAGE IS BLANK ...

Page 88: ...THIS PAGE IS BLANK ...

Page 92: ...2 THIS PAGE IS BLANK ...

Page 116: ...26 2 STD Taping Head 2010 May 26 Figure 10387 Upper Head 9 9 1 9 4 5 3 8 7 9 9 2 9 10 11 ...

Page 118: ...28 2 STD Taping Head 2010 May 28 Figure 10395 Upper and Lower Heads 4 2 1 6 3 3 5 6 4 5 ...

Page 126: ...2 STD Taping Head 2010 May 36 Figure 10389 Lower Head 9 11 7 2 3 8 5 4 1 9 9 10 9 9 9 ...

Page 128: ...38 THIS PAGE IS BLANK ...

Page 129: ...39 ...

Page 130: ...40 ...