Summary of Contents for 39600

Page 4: ...THIS PAGE IS BLANK ...

Page 6: ...THIS PAGE IS BLANK ...

Page 8: ...8 THIS PAGE IS BLANK ...

Page 10: ...THIS PAGE IS BLANK ...

Page 48: ...36 THIS PAGE IS BLANK ...

Page 50: ...38 THIS PAGE IS BLANK ...

Page 52: ...40 THIS PAGE IS BLANK ...

Page 53: ...41 16 TECHNICAL DIAGRAMS 16 1 Electric Diagram 2011 February 800at NA ...

Page 56: ...44 THIS PAGE IS BLANK ...

Page 58: ...46 2011 February 800at NA 800at Figure 10440 ...

Page 60: ...48 2011 February 800at NA 800at Figure 3269 ...

Page 62: ...50 2011 February 800at NA 800at Figure 5350 1 ...

Page 64: ...52 2011 February 800at NA 800at Figure 5817 ...

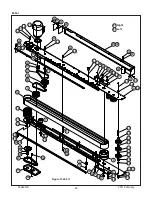

Page 66: ...54 2011 February 800at NA 800at Figure 6162 1 ...

Page 68: ...56 2011 February 800at NA 800at Figure 6162 2 OPTIONAL ...

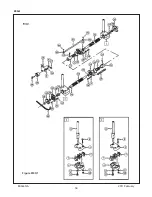

Page 70: ...58 2011 February 800at NA 800at Figure 6163 1 ...

Page 72: ...60 800at 2011 February 800at NA Figure 6163 2 Rear ...

Page 78: ...66 Figure 6165 800at 2011 February 800at NA ...

Page 80: ...Figure 6166 800at 2011 February 800at NA ...

Page 82: ...70 THIS PAGE IS BLANK ...

Page 84: ......

Page 86: ...THIS PAGE IS BLANK ...

Page 88: ...THIS PAGE IS BLANK ...

Page 92: ...2 THIS PAGE IS BLANK ...

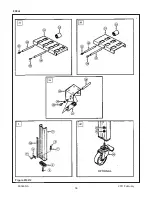

Page 116: ...26 2 STD Taping Head 2010 May 26 Figure 10387 Upper Head 9 9 1 9 4 5 3 8 7 9 9 2 9 10 11 ...

Page 118: ...28 2 STD Taping Head 2010 May 28 Figure 10395 Upper and Lower Heads 4 2 1 6 3 3 5 6 4 5 ...

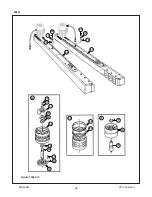

Page 126: ...2 STD Taping Head 2010 May 36 Figure 10389 Lower Head 9 11 7 2 3 8 5 4 1 9 9 10 9 9 9 ...

Page 128: ...38 THIS PAGE IS BLANK ...

Page 129: ...39 ...

Page 130: ...40 ...