NA - ENG

April 2016

3M-Matic

™

7000r-7000r3 Pro

Page 26

7.13 Electrical Connections and Controls

The electrical and pneumatic “On/

O

ff

” switch and the Push Button

Station “Start/Stop” are located on

the left side of the machine frame

(

Figure 7-14)

. If desired, for operator

convenience, the “On/O

ff

” and “Start/

Stop” switches can be relocated to

the right side of the machine frame.

A standard three conductor power

cord with plug is provided at the

back of the electrical control box for

(See Speci

fi

cations) electrical service.

The receptacle providing this service

shall be properly grounded. Before

the power cord is plugged into outlet

make sure that all packaging materials

and tools are removed from the machine.

Do not plug electrical cord into outlet

until ready to run machine.

Use of an extension cord is not recom-

mended. However, if one is needed for

temporary use, it must have a wire size

of 1.5mm diameter [AWG16], have a

maximum length of 30.5m [100 ft] and

must be properly grounded.

Note -

Machines outside the U.S. may

be equipped with 220/240 Volt, 50Hz

systems, or other electrical require-

ments compatible with local practice.

7.14 Initial Start-Up of Case Sealer

After completing the “Installation and

Set-Up” procedure, continue through

“Operation” for tape loading and

start-up to be sure case sealer is

properly adjusted to run boxes.

(Shown is

after Safety

Guard is

Removed)

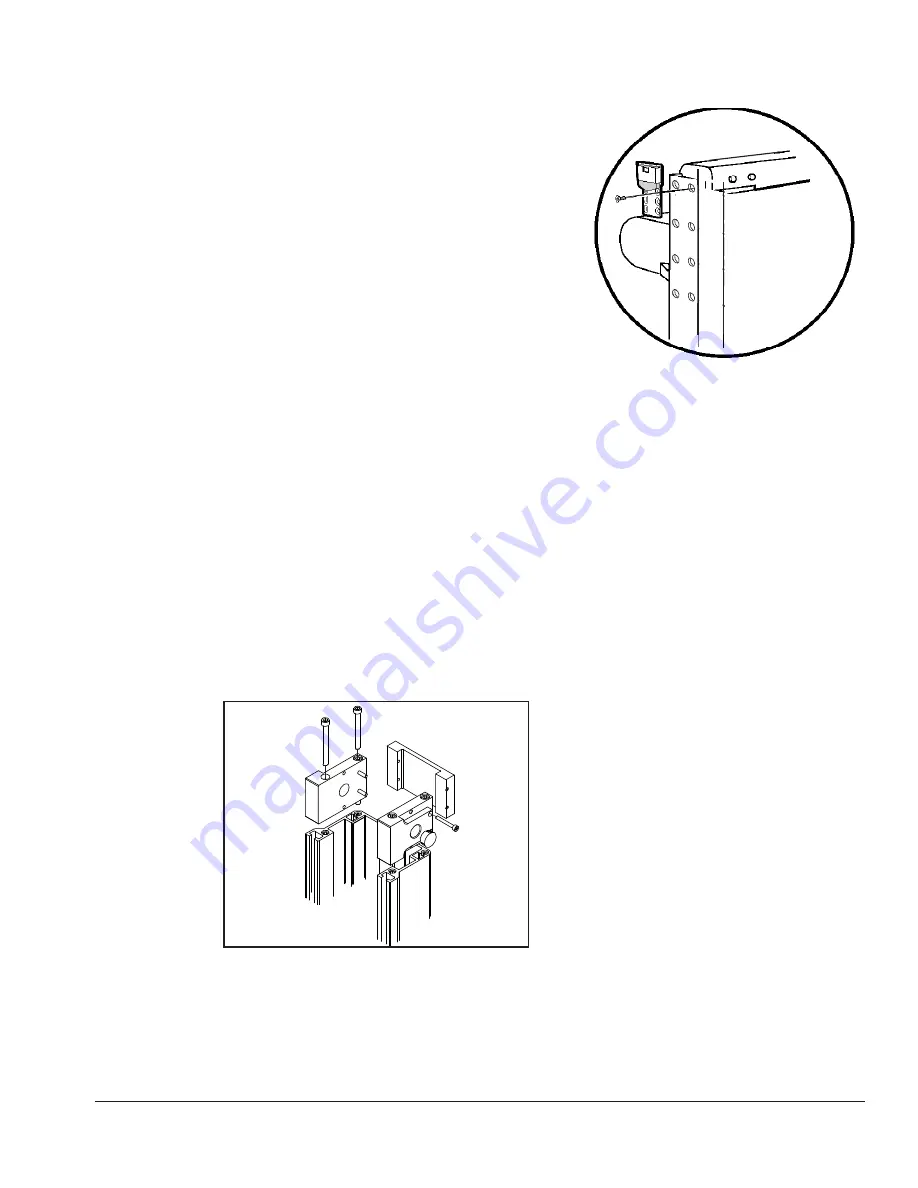

7.11 Column Cap and Bumper Supports

(Upper Drive Assembly)

With Safety Guard removed

- Figure 7-13:

(

Also See Special Set-Up Procedure -

Column Bumper Installation).

1) Install Column Cap (see Figure 7-12)

• Remove Column Cap and socket

head screw parts package from carton.

• Latching mechanism should be

installed on operator side column.

2) Install Bumper Supports

Raise and lock the upper drive

assembly in the raised position.

See Controls, Valves, Switch

Locations -

Section 7.

• Turn o

ff

air supply and electric power.

• Remove the Column Bumper and

fl

at

head screw parts package from carton.

• Using

fl

at head screws provided, install

Column Bumper (recommended

position is shown in

Figure 7-13).

• Install Safety Guard using socket

heads screws from parts package

Important:

Some bumper positions may

allow upper and lower taping heads to

come into contact with each other.

This creates added stress to bumper and/

or can cause a malfunction of machine.

For more information on bumper settings,

contact your 3M service representative.

7.12 Box Size Capacity of Case Sealer

At its factory setting, case sealer handles a

variety of box sizes. If larger capacity is

needed, machine can be adjusted to

accommodate larger boxes (refer to

Speci

fi

cations Section).

7. Installation

(continued)

Figure 7-13

Figure 7-12

Summary of Contents for 3M-Matic 7000r

Page 2: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page ii ...

Page 4: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page iv ...

Page 6: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page vi ...

Page 8: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page viii ...

Page 10: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page x ...

Page 30: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 18 ...

Page 62: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 50 ...

Page 64: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 52 ...

Page 72: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 60 ...

Page 92: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 80 ...

Page 94: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page ii ...

Page 96: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page iv ...

Page 98: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page vi ...

Page 102: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 2 ...

Page 120: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 20 ...

Page 122: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 22 ...

Page 140: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 40 ...

Page 141: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 41 ...

Page 142: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 42 ...

Page 144: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page ii ...

Page 146: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page iv ...

Page 148: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page vi ...

Page 152: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 2 ...

Page 170: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 20 ...

Page 172: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 22 ...

Page 190: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 40 ...

Page 191: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 41 ...

Page 192: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 42 ...