27

Pressure Regulator

regulates main air

pressure to the machine to adjust pressure, pull

knob up and turn – push down to lock setting.

Filter

removes dirt and moisture from plant

air before it enters the case sealer pneumatic

circuits. If water collects in bottom of bowl, lift

up on the valve on the bottom of bowl to drain.

3. Emergency Stop Switch

The machine electrical supply can be turned

off by pressing the latching emergency stop

switch. To restart machine, rotate emergency

stop switch (releases switch latch) and then

restart machine by pressing green (On) button

on side of machine frame.

4.

Raising Switch, Upper Drive Assembly

This switch, when touched by the leading

edge of a box, pneumatically raises the upper

frame to allow insertion of the box under the

drive belts. As the box moves under the switch,

releasing it, the upper drive assembly descends

on the box and the drive belts convey the box

through the machine. When switch is actuated

by hand, the upper drive assembly rises to its

maximum height. Released, the upper drive

assembly descends to its rest position.

5.

Centering Switch, Box Centering Guide

This pneumatic switch controls the box

centering guides. When switch is activated

by a box entering the case sealer, the

centering guides close (centering the box),

and released (after box passes over switch),

the guides open.

6.

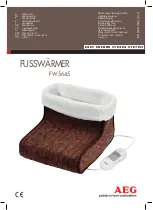

Air Pressure Regulator, Centering Guide

Force Adjustment – Figure 7-16

This regulator is used to adjust centering

guides according to weight of boxes.

Pressure should be adequate to center

boxes, but low enough to allow easy

pushing of boxes under taping head.

The regulator setting can be locked by

tightening the phillips screw as shown.

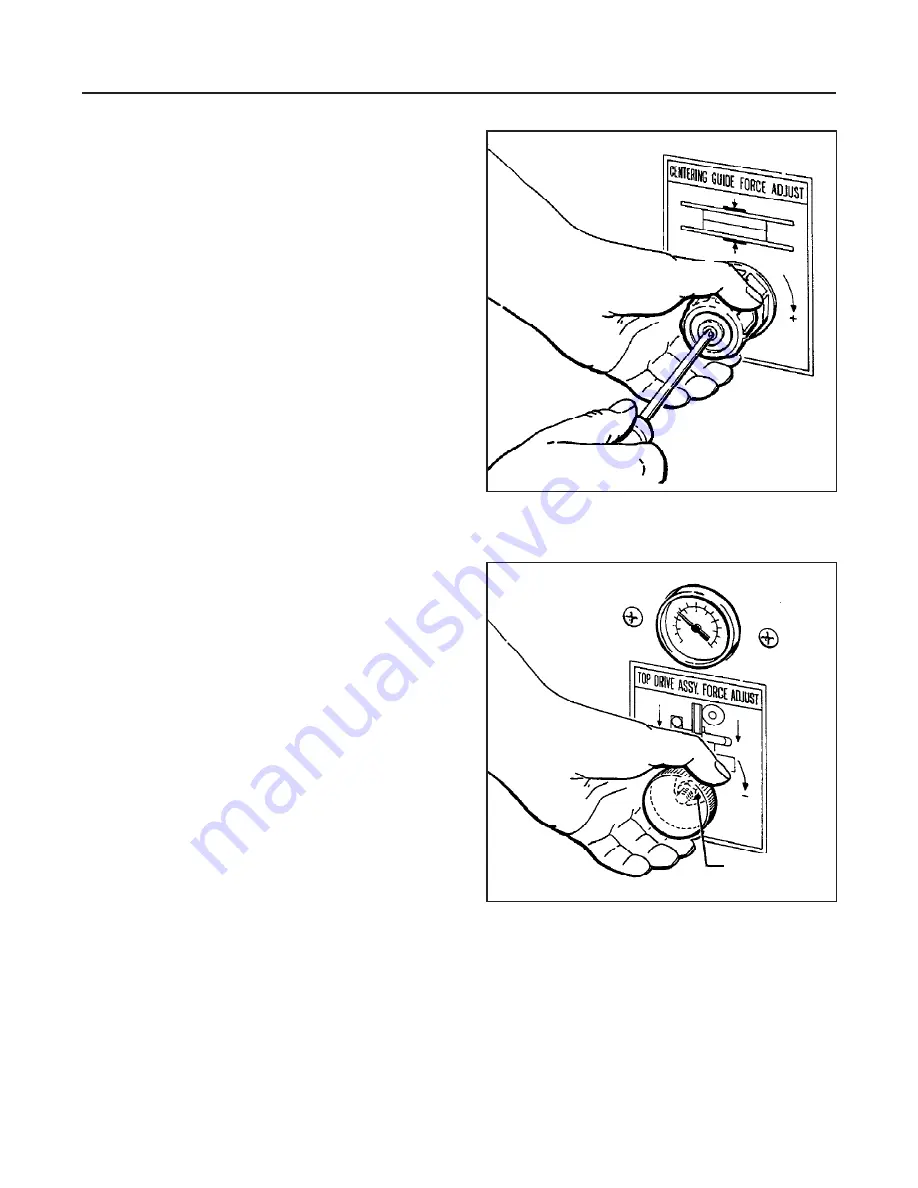

Figure 7-17 – Air Regulator/Gauge, Top Drive

Assembly

Figure 7-16– Air Regulator, Centering Guides

7.

Air Pressure Regulator/Gauge, Top Drive Assembly Force Adjustment – Figure 7-17

Set nominally to control "down" movement of top drive assembly and the pressure exerted against the box.

The regulator setting is changed as necessary for the boxes being sealed to provide adequate drive belt

pressure against the box to positively convey the boxes through the machine. If the boxes stop or hesitate

while being conveyed, decrease the regulator pressure which will increase the drive belt force on the box

for more friction between the box and drive belts. Adjust setting as necessary to get continuous movement

of boxes through machine.

700r3-NA

2012 January

7-INSTALLATION AND Setup

(continued)

Locking

Nut

Summary of Contents for 3M-Matic 700r3

Page 2: ......

Page 6: ...6 THIS PAGE IS BLANK ...

Page 8: ...iv THIS PAGE IS BLANK ...

Page 60: ...50 THIS PAGE IS BLANK 700r3 NA 2012 January ...

Page 62: ...52 THIS PAGE IS BLANK 700r3 NA 2012 January ...

Page 64: ...54 16 TECHNICAL DIAGRAMS 16 1 Electric Diagram 700r3 NA 2012 January ...

Page 66: ...56 THIS PAGE IS BLANK ...

Page 68: ...58 THIS PAGE IS BLANK ...

Page 70: ...60 THIS PAGE IS BLANK ...

Page 96: ...86 THIS PAGE IS BLANK ...

Page 98: ......

Page 100: ...THIS PAGE IS BLANK ...

Page 102: ...THIS PAGE IS BLANK ...

Page 106: ...2 THIS PAGE IS BLANK ...

Page 126: ...22 AccuGlide 3 3 NA 2012 January Figure 10932 Upper Head AccuGlide 3 3 ...

Page 142: ...THIS PAGE IS BLANK ...

Page 143: ......

Page 144: ......