16

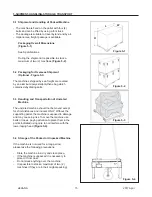

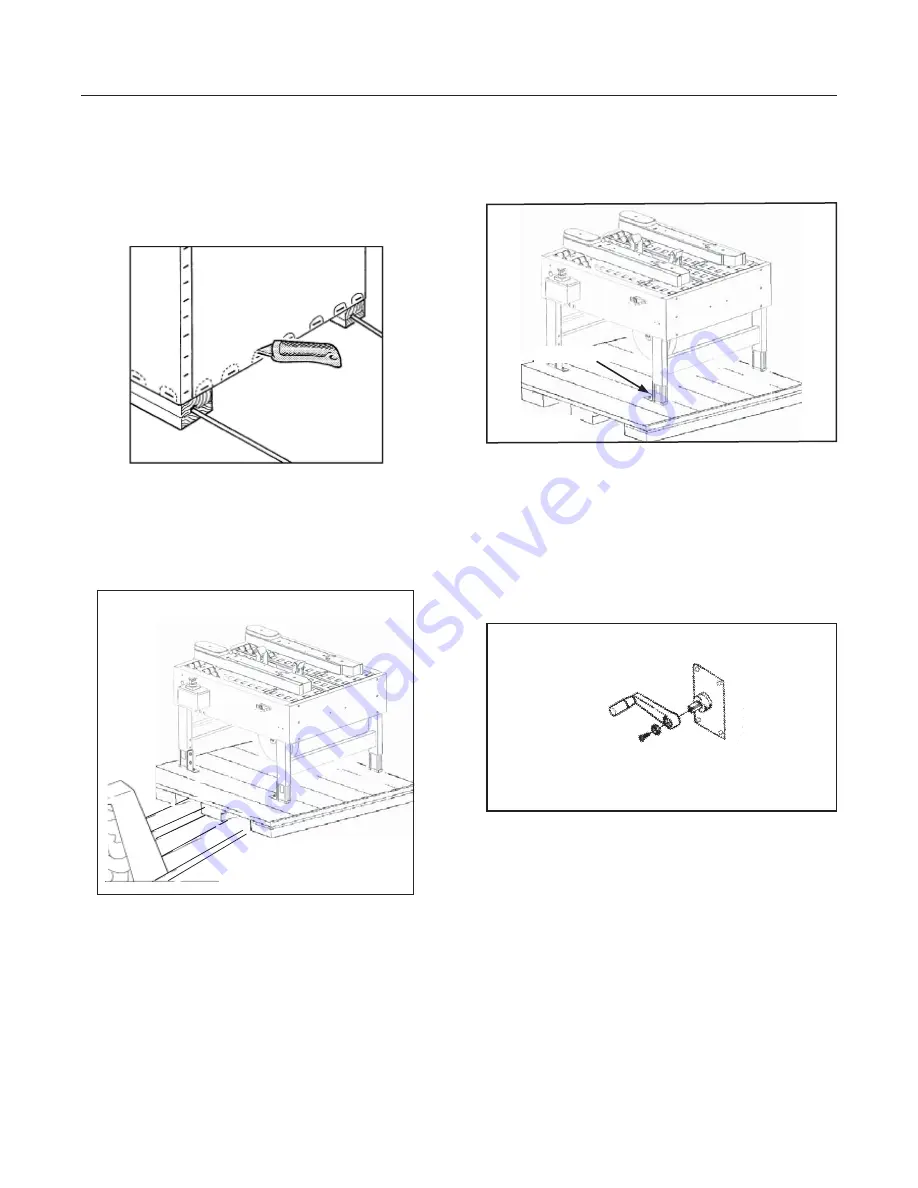

6.1 Uncrating

Cut straps. Cut out staple positions along the

bottom of the shipping box or remove staples

with an appropriate tool

(Figure 6-1)

After cutting out or removing the staples, lift the

shipping box in order to clear the machine

Note:

Two (2) persons required.

Transport the machine with a fork-lift truck to

the operating position. Lift the pallet at the point

indicated in

Figure 6-2

(weight of m pallet = see

Section 4

).

Removal of Pallet

Using a 10mm combination wrench, remove the

fasteners that secure the case sealer legs to pallet

at each leg (as shown in

Figure 6-3).

6.2 Disposal of Packaging Materials

The

a80b

package is composed of:

- Wooden pallet

- Cardboard shipping box

- Wooden supports

- Metal

fi

xing brackets

- PU foam protection

- PP plastic straps

- Dehydrating salts in bag

- Special bag of laminated polyester/aluminium/

Polyethylene (sea freight package only)

- Polyethylene protective material

For the disposal of the above materials, please follow

the environmental directives or the law in your country.

6-UNPACKING

Figure 6-1

Figure 6-3

Figure 6-2

2011 April

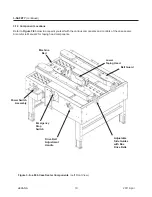

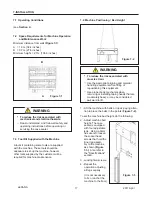

Locate on the machine (or in the spare parts box)

the Drive Belt Adjustment handle. Using a 3mm hex

wrench, install the handle on the side of the machine

pointing outward (as shown in

Figure 6-4).

a80b-NA

Fasteners

Remove the leg height adjustment cap screws and

replace with the cap screws from the tool kit. Loosen

both cap screws. Remove and replace them one at

a time to keep the inner threaded plate in position.

Figure 6-4

Belt Width

Adjustment

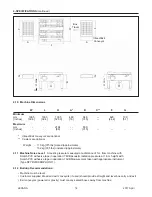

Summary of Contents for 3M-Matic a80b

Page 4: ...THIS PAGE IS BLANK ...

Page 6: ...6 THIS PAGE IS BLANK ...

Page 8: ...THIS PAGE IS BLANK ...

Page 42: ...32 THIS PAGE IS BLANK ...

Page 43: ...33 2011 April a80b NA 16 TECHNICAL DIAGRAMS continued 16 1 Electric Diagram ...

Page 46: ...36 THIS PAGE IS BLANK ...

Page 56: ...46 2011 April a80b NA Figure 10916 a80b ...

Page 58: ...48 THIS PAGE IS BLANK ...