Summary of Contents for 3M-Matic a80b

Page 4: ...THIS PAGE IS BLANK ...

Page 6: ...6 THIS PAGE IS BLANK ...

Page 8: ...THIS PAGE IS BLANK ...

Page 42: ...32 THIS PAGE IS BLANK ...

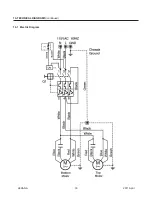

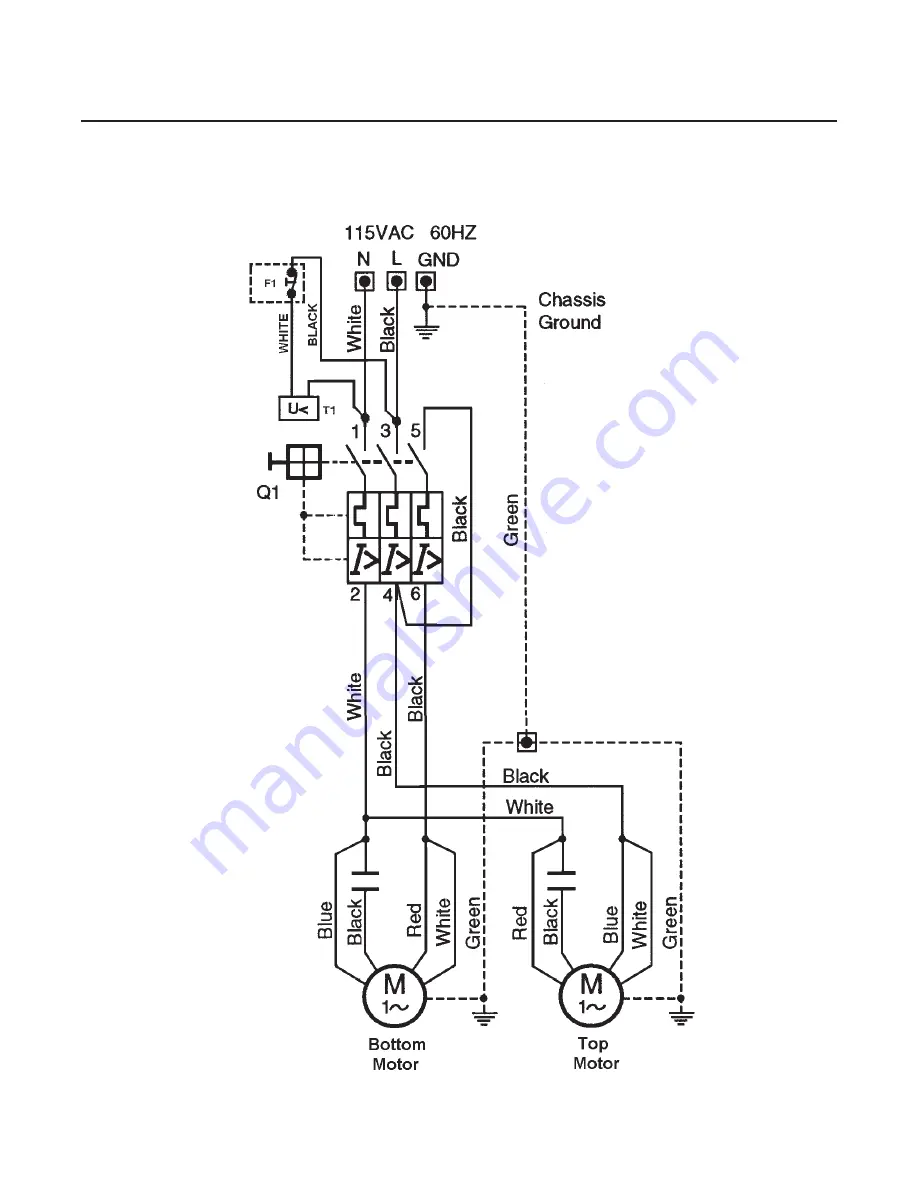

Page 43: ...33 2011 April a80b NA 16 TECHNICAL DIAGRAMS continued 16 1 Electric Diagram ...

Page 46: ...36 THIS PAGE IS BLANK ...

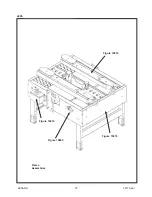

Page 56: ...46 2011 April a80b NA Figure 10916 a80b ...

Page 58: ...48 THIS PAGE IS BLANK ...