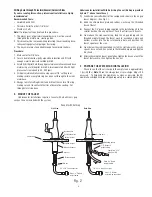

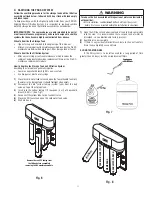

The drain saddle should always be installed above (before) the trap

and on the vertical or horizontal tailpiece. Never install the drain saddle

close to the outlet of a garbage disposal because plugging of the RO

drain line may occur. (See Fig. 4)

1) Remove backing on foam seal and place over hole on threaded half

of the drain saddle. Place drain saddle at the selected location and

mark the pipe through the threaded opening.

2) Drill a 1/4” hole at the marked location through one side of the

drain tailpiece.

3) Position both halves of the drain saddle on the drain pipe so that the

threaded opening is lined up with the hole in the drain pipe.

4) Use the screws and nuts to clamp the drain saddle onto the

drain pipe. Make sure that there is equal space between saddle

halves on each side. Do not overtighten (See Fig. 5).

5) Screw in elbow and orient toward the RO faucet.

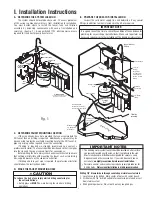

J. INSTALL THE FILTRATION ASSEMBLY AND STORAGE TANK

Undercounter Installation:

The filtration assembly is usually mounted to the right or the left

side wall inside of the sink cabinet, taking into consideration the space

available and the tank location. Generally, the storage tank is placed in

the rear of the sink cabinet while the filtration assembly is positioned

toward the front for replacement filter accessibility.

Install screws and washers halfway, so you can easily slip the

bracket to wall before firmly setting screws.

NOTE:

If you are mounting

onto sheetrock or drywall, use anchors or screws (not included).

NOTE: It is essential that the filters be installed in the correct location.

Use the icon coded labels to match the replacement filters with their

corresponding filter heads.

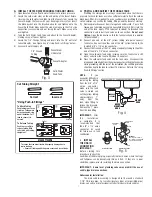

STEP 1: Cut open the sealed plastic bag and remove the Pro RO

membrane module.

STEP 2: Remove the white plug from the fitting at the bottom of the

module by pushing in the small white collet and pulling out the plug

simultaneously. See “Using Push-in Fittings” on previous page

STEP 3: Remove the sanitary protective cap from the top of the module.

STEP 4: Connect the red SFC reject tubing by inserting it into the fitting

as far as it will go, located at the bottom of the Pro RO membrane

module. Line up the module ears (See Fig 6), insert the module and

push it into the head until it is fully seated. Twist the module 1/4 turn to

the right to lock it into place. The final orientation should be such that

the module fitting is located towards the rear.

STEP 5: Install remaining replacement filters into their respective filter

heads using the icon coded labels, matching the replacement filters with

their corresponding filter heads (See Fig 6).

To mount the filtration assembly, elevate it at least 2” (5 cm) off

of the cabinet floor and, while keeping it level, mark the location of the

mounting holes on the cabinet side wall. Make small pilot holes with an

awl or a drill and screw in the two mounting screws; leaving just enough

protruding to allow the bracket mounting slots to slide over them.

NOTE:

If the cabinet side walls are not of solid construction, the

filtration assembly can be set on the cabinet floor and held against the

side wall with the mounting screws. However, the filtration assembly

will then need to be lifted from the mounting screws in order to remove

the replacement filters.

The storage tank may be oriented either vertically or horizontally. It is

generally placed to the rear of the cabinet but can be set in the front

center (between the sink basins) for ease of access if space permits.

K. MAKE THE TUBING CONNECTIONS

With all of the components in place, the tubing connections can

be made. When routing the tubing between the components, several

guidelines should be observed.

• Tubing runs should generally follow the contour of the cabinet

rather than interfere with the cabinet storage area.

• Strive for a neat and orderly tubing “flow” by using fasteners (e.g.

insulated staples) to secure the tubing.

• Arrange the tubing so that there are no sharp bends. Leave some

“play” in the tubing for ease of servicing, then cut the tubing to the

desired length.

• Try to keep the tubing from the filtration assembly to the tank

and faucet as short as practical for good flow.

Undercounter Installation:

The filtration system will use 1/4” orange, 1/4” green, 3/8” blue,

3/8” black and 3/8” yellow tubing supplied with the system.

1)

The 1/4” orange tubing should have already been connected to

the feedwater connection under Section G. Insert the other end into

the “Feed” connection labeled on the filtration system (right side).

2)

Attach the 1/4” x 3/8” union to 1/4” blue tubing on faucet.

3)

Insert one end of the 3/8” blue tubing into the “Faucet” connection

labeled on the filtration system (left side), and the other end into

the 1/4” x 3/8” union per Step 2.

4)

Connect the 3/8” black tubing from the air gap faucet to the

drain saddle so that it slopes continuously downward without any

loops or low spots. Cut the tubing to the proper length and connect

it to the drain elbow.

5)

Insert one end of the 3/8” yellow tubing into the “Tank”

connection labeled on the filtration system, and the other end into

the tank valve.

6)

Route the special red SFC tubing with 1/4” union connector from

the Pro RO membrane module to the 1/4” green tubing connected

to the faucet.

Do not cut this special SFC tubing.

It’s length is

important to maintain proper efficiency and performance.

L. START UP THE SYSTEM

1)

Double check to see that all of the connections are secure.

2)

Open the cold water feed valve and check the system for

leaks. If any leaks are detected, close the valve and correct the

problem before proceeding.

NOTE:

If a leak occurs at a “Push In”

plastic fitting, then refer to page 7, “Using Push-In Fittings”.

3)

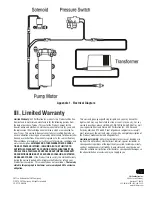

Plug the booster pump transformer into a non-switched 110V, 60Hz

power source and connect to the system harness (See Appendix 1).

4)

Open the faucet and the storage tank valve until a steady stream

of water flows. Close the faucet, wait at least five (5) minutes and

carefully check for leaks. Correct them as necessary.

M. FLUSH THE SYSTEM AND CHECK OPERATION

1)

With the tank valve closed (the tank should still contain the

sanitizing solution at this point), open the faucet and feedwater

valve. Water should begin to drip from the faucet within several

minutes. Continue to flush the system for 24 hours. Water will

steadily drip from the faucet at the time. During this procedure, the

tank is being intentionally bypassed in order to thoroughly sanitize

the tank and also flush the membrane of any sanitizer.

2)

After flushing for 24 hours, open the tank valve and the faucet again

and allow the tank to completely empty. When the water begins to

drip steadily from the faucet the tank should be empty.

3)

Close the faucet and reinspect the system for leaks. Allow the tank

to fill completely (it will take approximately 4 hours), then drain the

tank again. The water should be discarded because it may contain

small amounts of household bleach.

4)

The system should be ready to use as soon as the tank refills.

If any objectionable taste is noticed after the second tankful is

drained, drain the tank the following day.

8