EO Abator Operation and Installation Manual

12

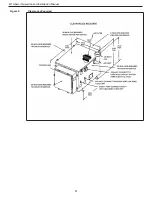

Section 3: Installation Requirements

General Electrical Requirements

All internal wiring within the EO Abator system has been connected at the factory. External wiring must be in

accordance with local and/or national codes and plant procedures.

Connect a dedicated service to the main circuit breaker located inside the control box. A main disconnect is not

provided on the EO Abator System and needs to be included in the building installation. It must be mounted in close

proximity to the EO Abator system within easy reach of the operator, and shall be marked as the disconnecting device

for the EO Abator system.

If connecting Model 50AN to 208 VAC single phase service, use a boost transformer to bring the voltage to 220 VAC

(recommended 7.5 to 10 KVA Boost transformer).

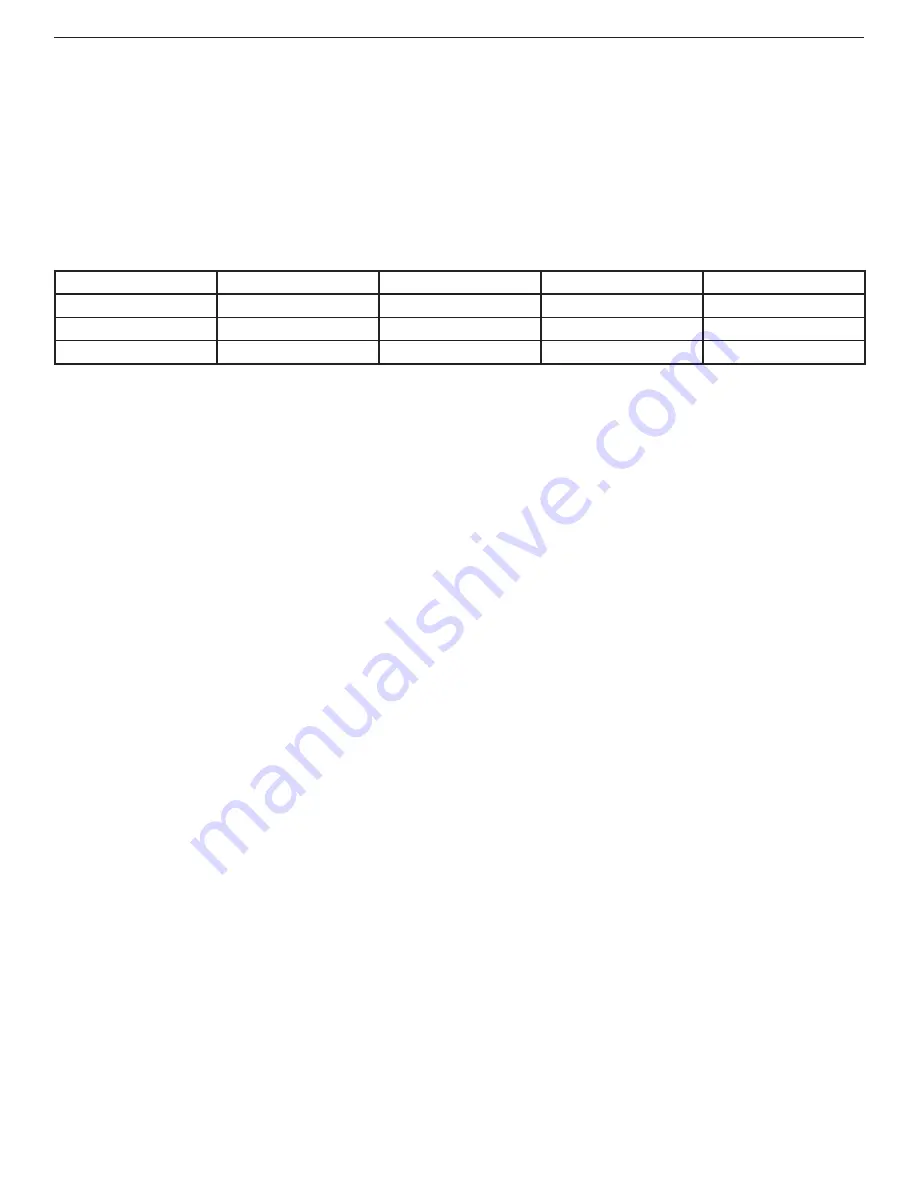

Model

Voltage

Current Rating

Main Breaker

Frequency

50AN

220-230VAC, 1 Phase

30A

40A

50/60Hz

50AE

400VAC, 3 Phase

17A

20A

50/60Hz

50AJ

200VAC, 3 Phase

28A

40A

50/60Hz

Electrical Requirements: Models 5XL, 8XL and GS Series Sterilizers

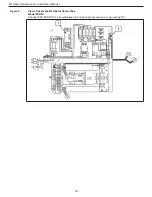

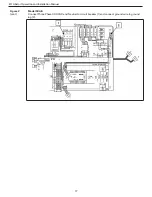

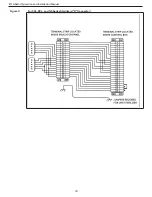

Connect corresponding wire numbers between indicator panel terminal strip and the control box terminal strip (see

Figures 2, 3, 5, and 6). Use three-pair (6 wire) shielded cables (recommended Belden 18 AWG Part #83656) and

limit the length of the wire to 40 M (130 ft.). The shield on the control panel end of the cable must be connected to

the ground lug in the control panel. A ground wire from the indicator panel to the EO Abator system is required. If the

indicator panel is within 12 M (40 ft.) from the EO Abator system, a 12 AWG ground wire should be used. If the length

is 12-24 M (41-80 ft.), a 10 AWG ground wire should be used. For 25-40 M (81-130 ft.) length, an 8 AWG ground wire

should be used.

In no case is the indicator panel to be mounted more than a maximum of 40 M (130 ft.) away from

the EO Abator system. The indicator panel must be located in the sterilizer area.

A ground wire from the ground lug in the control panel to earth ground is required. Use the same wire criteria as listed

above for the indicator panel to determine the proper wire AWG for the distance run between the control panel and

earth ground.

Using the DB-15 connector(s) with cable, connect wiring between the sterilizer(s) and the EO Abator system indicator

panel (see Figures 2, 3, 5, and 6). Install cable between the EO Abator system indicator panel and the Abator using 6

conductor 18 AWG shielded cable (recommended Belden Part #83656). A 3M service representative will connect the

wires to the Abator terminal strip.

When connecting only one sterilizer, a jumper wire must be connected from terminal 27 to 25 and from terminal 28 to

26 inside the control box.

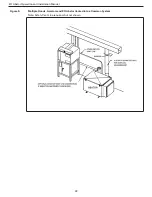

EO Inlet Line Requirements – Vent Line from Sterilizer to Abator

A combination of two Steri-Vac gas sterilizers Model 5XL, 8XL, or GS Series sterilizer may be vented through a common

vent line to the EO Abator system.

Note:

The Model 5XL or Model 8XL sterilizers CANNOT be combined with a GS Series sterilizer when connecting to

an Abator.

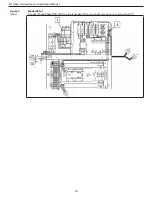

Connect the sterilizer vent line to the EO Abator system’s 1.9 cm (3/4 in.) National Pipe Thread (NPT) EO inlet. An

adapter may be needed to facilitate the need for a 2.5 cm (1.0 in.) vent line. See Figure 5.

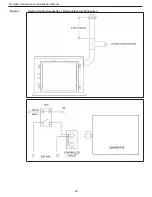

The diameter of the vent line used for the EO inlet and safety vent depends on the combined length of the two vent lines.

Use 2.5 cm (1 in.) to 3.8 cm (1.5 inch) copper tubing to connect sterilizer discharge to the EO Abator system EO inlet.

Refer to table for line sizes. Use a 1.9 cm (3/4 in.) National Pipe Thread (NPT) connection at the EO Abator system.

Avoid sags or loops in all lines to prevent moisture buildup at other points in the line. Ensure that the vent line is gas tight