6

NOTICE

To reduce the risk associated with water leakage or flooding:

• Change the disposable pre-filter at the recommended interval; the disposable pre-filter

MUST be replaced every 12 months or sooner.

• Change the disposable filter RO membrane at the recommended interval; the

disposable RO membrane MUST be replaced every 24 months or sooner.

• Failure to replace the disposable pre-filter and RO membrane at recommended

intervals may lead to reduced filter performance and failure of the filter, causing

property damage from water leakage or flooding.

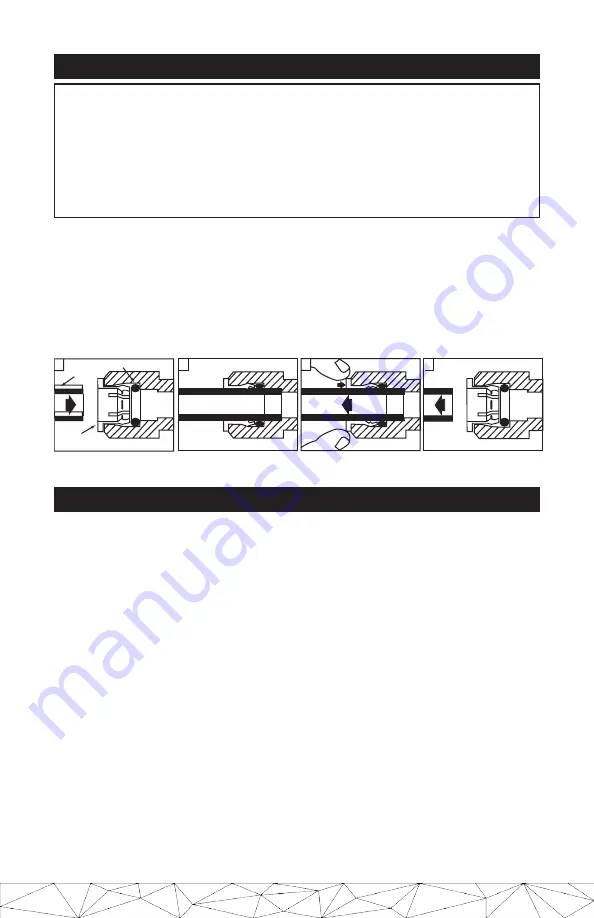

This product is outfitted with user friendly ‘Push In’ connectors. Proper use of the

connectors is shown in the diagrams. It is most important that the tubing selected for use

with these connectors be of high quality, exact size and roundness, and with no surface

nicks or scratches. If it is necessary to cut the tubing, use a plastic tubing cutter or sharp

razor knife. Make a clean square cut.

Should a leak occur at a ‘Push-In’ connector, the cause is usually a problem with the tubing.

To Fix:

1. Relieve pressure.

4. Reattach tubing

2. Release tubing

5. Confirm connection is leak free

3. Cut off at least

1/4”from end

HOW TO USE ‘PUSH-IN’ FITTING

SYSTEM START-UP

1. Remove the pre-filter cartridge from its packaging. Remove the red cap from the

cartridge and moisten the o-rings with water. Insert the cartridge into the filter head.

Then, turn the cartridge 1/4 turn to the right.

2a. For SGLP100-CL and SGLP100-CL-BP, remove the red cap from the RO-membrane

cartridge and moisten the o-rings with water. Insert the cartridge into the filter head.

Then, turn the cartridge 1/4 turn to the right.

2b. For SGLP200-CL and SGLP200-CL-BP, remove the red caps from both the RO-

membrane cartridges and moisten the o-rings with water. Insert the RO-membrane

cartridges into the filter heads. Ensure that the RO-cartridge with the blue-control is

inserted into the RIGHT-side head, while the other RO-membrane cartridge is inserted

into the LEFT-side head. Turn both the RO-membrane cartridges 1/4 turn to the right.

3. Check that all plumbing connections are secure.

4. Open the tank shut-off valve. Turn on the incoming water supply or beverage booster

pump (if applicable) and check the system for leaks. If any leaks are noted, turn off the

water supply and/or booster pump and correct the leak before proceeding. If a leak is

detected at a push-in fitting, refer to Figure 2.

5. Open downstream valve (not included) and let water run through the RO to drain for

10 minutes.

6. Close sample valve.

7. Allow tank to fill (Approximately 60 minutes).

8. Open Water Sample Valve outlet to drain. Empty tank. Water flowing from tank will

reduce to a fast drip when tank is empty.

9. Allow product water to run to drain for 24 hours.

10. Close sample valve and allow the tank to fill (Approximately 60 minutes).

11. System is now ready for use.

Figure 2

1

Push in collet to release tubing.

2

Tubing is secured in.

Grey Collet

Tube O-Ring

1

Pull tubing straight out.

2

g

n

i

b

u

T

e

s

a

e

l

e

R

o

T

g

n

i

b

u

T

h

c

a

tt

A

o

T

Push tubing straight in as far

as it will go.

Summary of Contents for 5636201

Page 12: ...11 Figure 5 5 8 4X 10 1 2 2X 3 4 4X 9 2X 3 8 8X 1 4 4X ...

Page 14: ...13 ...

Page 15: ...14 NOTES ...