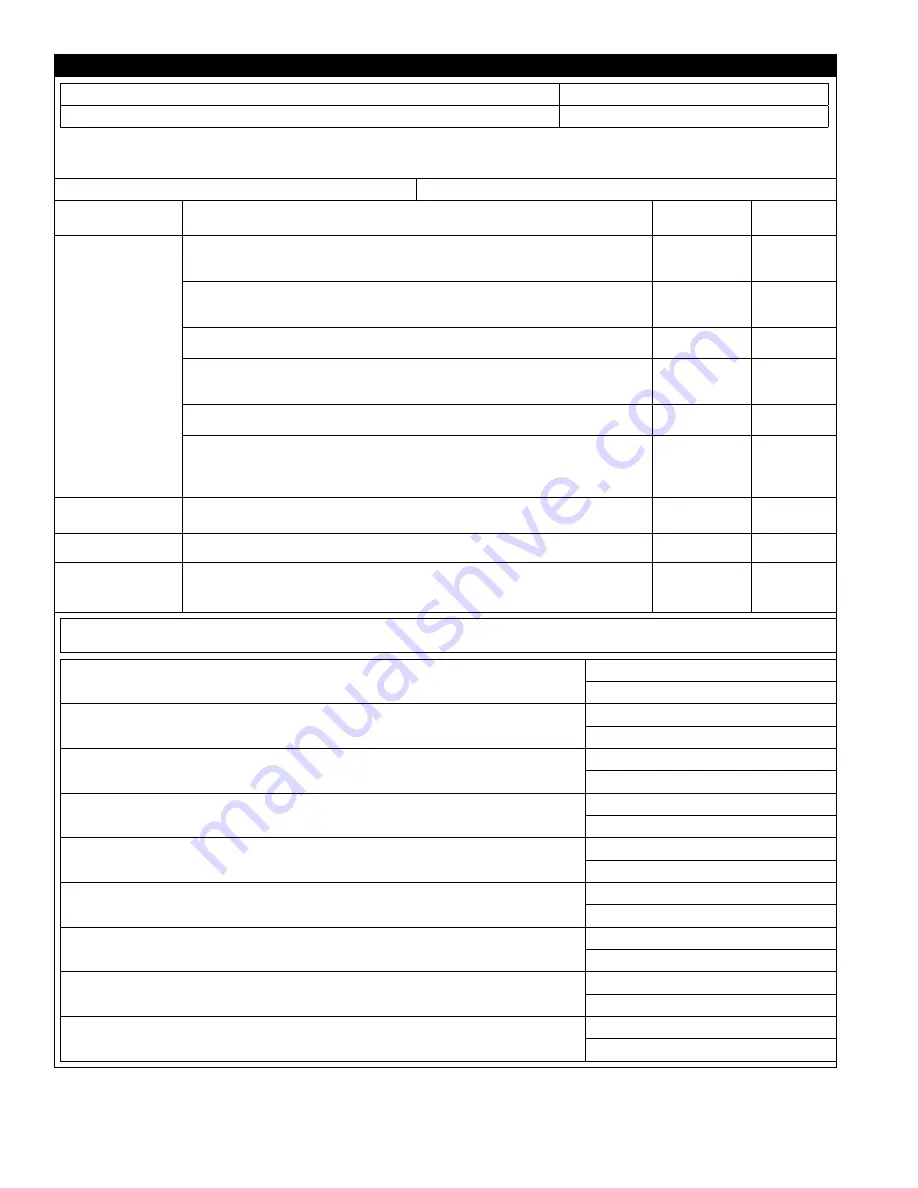

Table 2 – Inspection and Maintenance Log

Serial Number(s):

Date Purchased:

Model Number:

Date of First Use:

Instructions:

Record the results of each inspection on copies of this checklist. Additional copies of this checklist can be

printed from the Adobe Acrobat PDF version this manual. (www.3M.com/FallProtection)

Inspection Date:

Inspected By:

Components:

Inspection:

(See Section 1 for

Inspection Frequency

)

User

Competent

Person

Inspection

Notes:

Glyde-Saf HD Fall

Arrest System

components.

(See Figure 2)

Inspect entire system for damage, deformation, corrosion, or rust. Look for

cracks, bends, dents, or wear that could affect strength and operation of

the system.

X

X

Confirm that End Stops are installed at each end of the Glyde-Saf HD Fall

Arrest System. See Section 3.2 Assembly of the Glyde-Saf HD Fall Arrest

System.

X

X

Visually inspect fasteners that secure the Glyde-Saf HD Fall Arrest System

Trolley Rail Tracks to the intermediate brackets.

X

X

Inspect the Trolley Rail Tracks for structural defects. Rail Tracks must be

straight without any bends or dents. Trolley wheels must roll freely in the

rail. Remove debris and replace damaged components as needed.

X

X

Inspect the joints between Trolley Rail Tracks for structural defects or

damage including bends, cracks, corrosion, etc.

X

Inspect fasteners that secure the joints between Trolley Rail Tracks. Ensure

fasteners are torqued to 60 ft*lbs (81 Nm).

X

Inspect all other fasteners. Ensure that 3/4 in bolts are torqued to

130 ft*lbs (176 Nm). Re-torque as necessary.

Trolley

Remove and inspect Trolley for damage. Trolley wheels should spin freely

and show minimal wear. Replace Trolley wheels as needed.

X

Labels

Verify that all labels are securely attached and are legible (see

“Labels”

)

X

X

PFAS and Other

Equipment

Additional Personal Fall Arrest System (PFAS) equipment (harness, SRL,

etc) that are used with the Flexiguard Glyde-Saf HD Fall Arrest System

should be installed and inspected per the manufacturer’s instructions.

X

X

IMPORTANT:

Extreme working conditions (harsh environment, prolonged use, etc.) may require more frequent inspections. If you have

questions on the use, care, or suitability of this equipment for your application, please contact 3M Fall Protection.

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Corrective Action/Maintenance:

Approved By:

Date:

Summary of Contents for 8530637

Page 3: ...3 6 A B A B 50 ft 15 2 m 6 ft 1 8 m 6 ft 1 8 m 7 8 ...

Page 4: ...4 9 ...

Page 13: ......