© 3M 2018

Certi

fi

ed to

Certi

fi

ed by

ANSI Z359.4 : 2013

BSI Certified Product

NFPA 1983 : 2017

Lic. BMP 689957

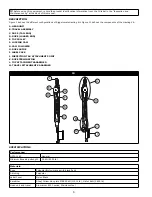

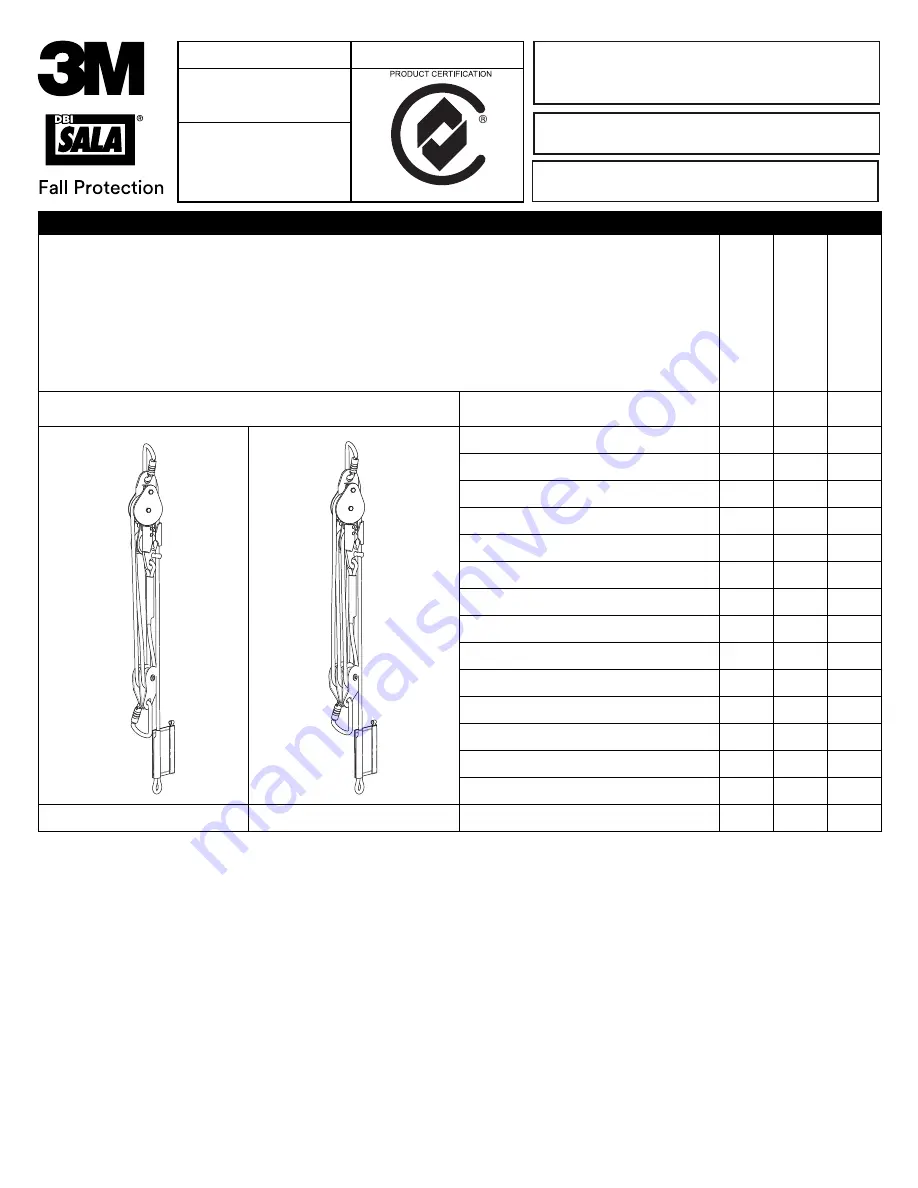

Riggersmate Hauling Kits

DBI SALA

ROLLGLISS TECHNICAL RESCUE

1

W

orking Length (m)

R

ope length (m)

Mechanical Adv

antage

Part Number

1

2

3

8704103

5

25

4:1

8704104

10

50

4:1

8704105

15

75

4:1

8704106

20

100 4:1

8704107

30

150 4:1

8704108

40

200 4:1

8704109

50

250 4:1

8705103

2

14

6:1

8705104

10

70

6:1

8705105

15

105 6:1

8705106

20

140 6:1

8705107

25

175 6:1

8705108

30

210 6:1

8705110

40

280 6:1

8704XXX

8705XXX

8705113

5

35

6:1

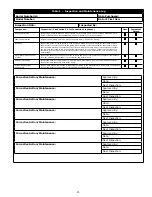

USER INSTRUCTION MANUAL

Form No: A019 Rev: A