23

Bair Hugger Model 750 Temperature Management Unit Service Manual

English 202522A

Check the 3M

TM

Bair Hugger

TM

therapy website to ensure you have the most recent version of this document.

www.bairhugger.com reorder #202522A

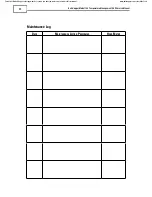

5� Using the medium Phillips screwdriver, remove the four screws that hold the chassis assembly to the

top enclosure (Figure 2)�

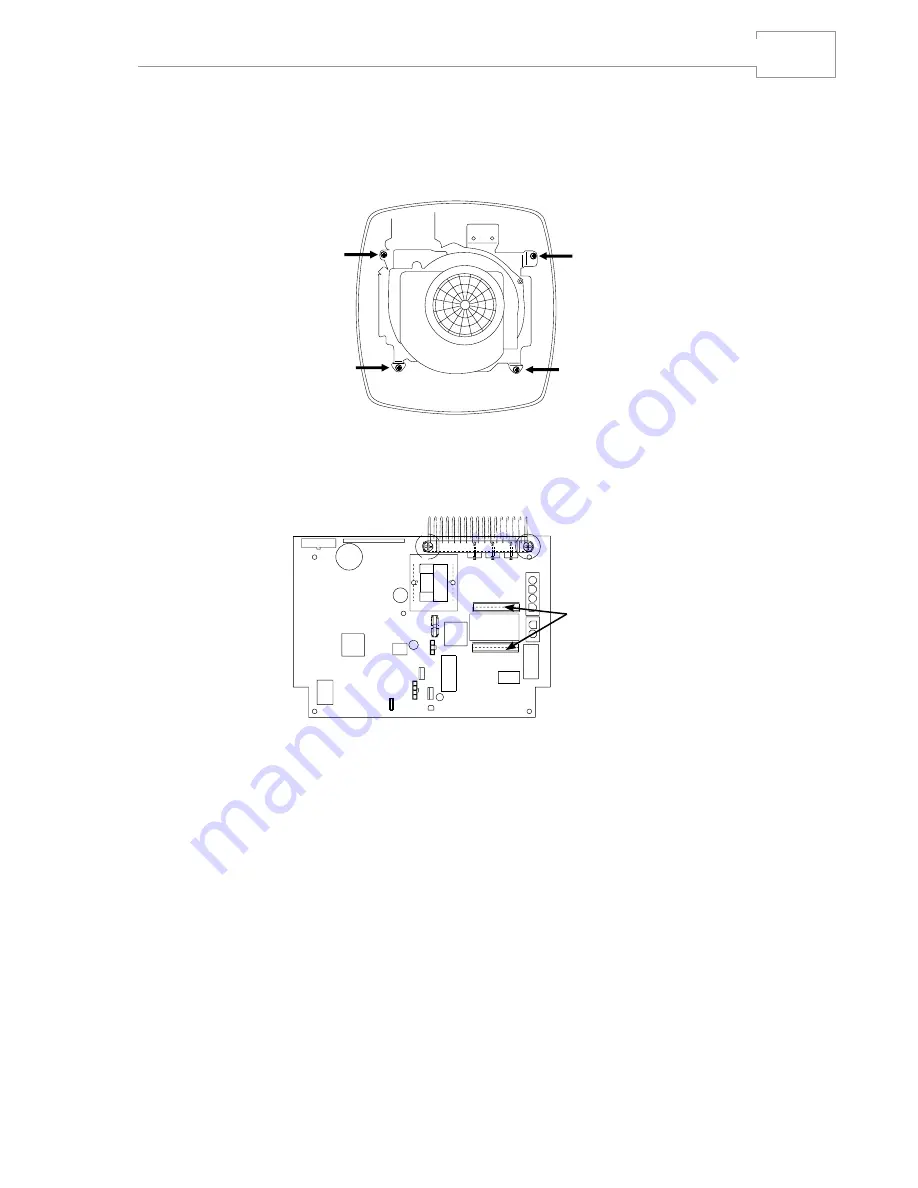

6� Unplug the user interface and LCD connector to remove the top enclosure� If needed, use a flat

screwdriver to lift and release the snap-fit LCD connector�

7� Replace fuses�

fuses

Reassembling the Temperature Management Unit

1� Plug in the user interface and LCD connectors�

2� Attach the chassis assembly to the top enclosure with the 4 screws�

3� Screw in the two ground wires (with the 2 screws)�

4� Plug in the 2-pin black connector�

5� Attach the bottom to the top enclosure with the 4 screws�

6� Attach the IV pole clamp or plug (with the 2 pole clamp screws)�

7� Reattach the hose (see reattaching the hose on page 21 for instructions)�