14

3M™ Bair Hugger™ Warming Unit Model 775 – Service Manual

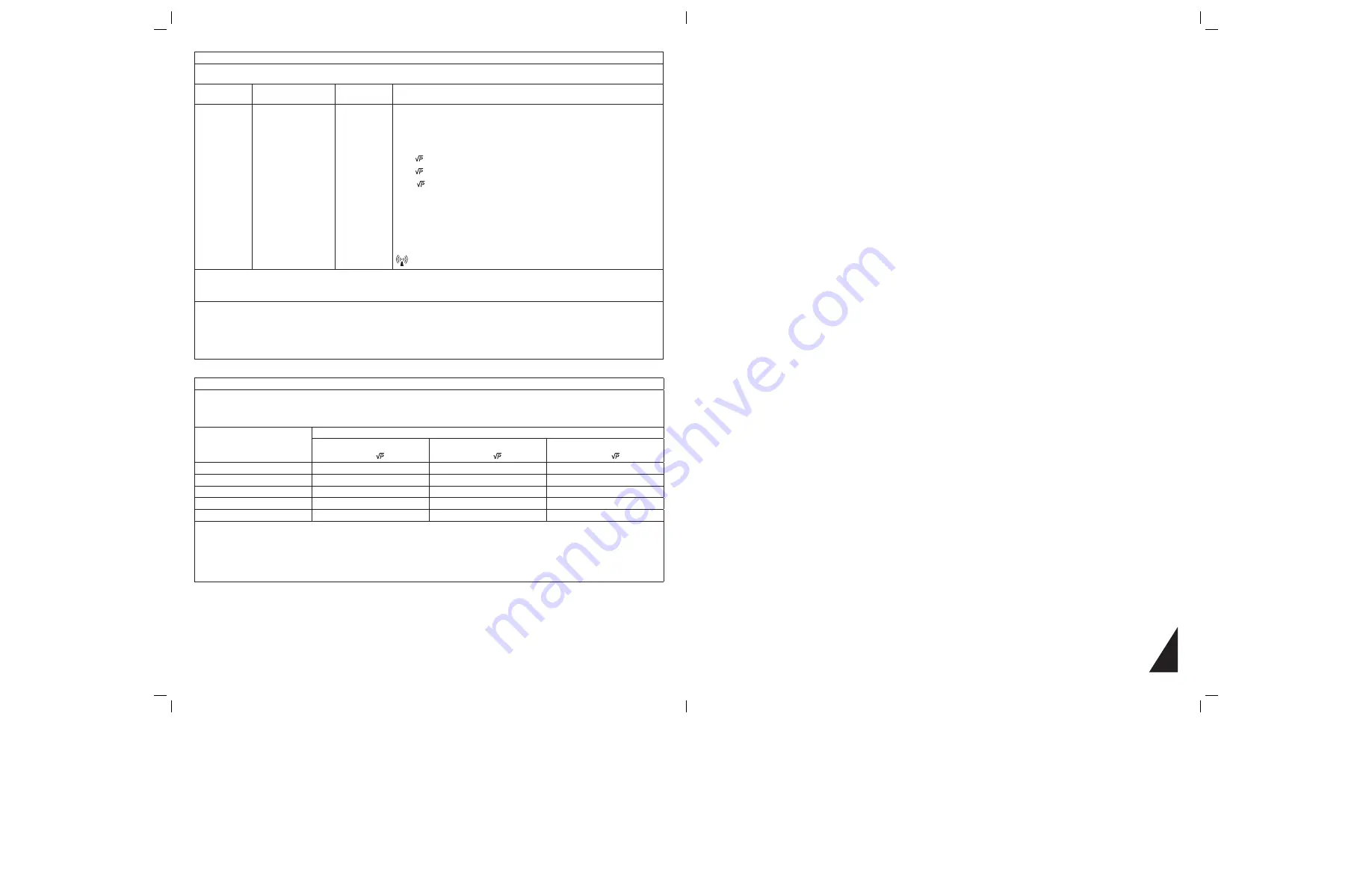

Guidance and manufacturer’s declaration – electromagnetic immunity

The Model 775 warming unit is intended for use in the electromagnetic environment specified below. The customer or the user of the Model

775 warming should assure that it is used in such an environment.

Immunity Test

IEC 60601 test level

Compliance

level

Electromagnetic environment ‑ guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2,5 GHz

3 Vrms

3 V/m

Portable and mobile RF communications equipment should be used no closer to

any part of the Model 775 warming unit, including cables, than the recommended

separation distance calculated from the equation applicable to the frequency of

the transmitter.

Recommended separation distance

d = 1.2

d = 1.2

80 MHz to 800 MHz

d = 2.3 800 MHz to 2,5 GHz

where P is the maximum output power rating of the transmitter in watts (W) according

to the transmitter manufacturer and d is the recommended separation distance in

meters (m).

Field strengths from fixed RF transmitters, as determined by an electromagnetic site

survey

a

, should be less than the compliance level in each frequency range.

b

Interference may occur in the vicinity of equipment marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects

and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and

FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF

transmitters, an electromagnetic site survey should be considered. If the measured field strength in the location in which the Model 775 warming unit

is used exceeds the applicable RF compliance level above, the Model 775 warming unit should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as re-orienting or relocating the Model 775 warming unit.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

Recommended separation distances between portable and mobile RF communications equipment and the Model 775 warming unit

The Model 775 warming unit is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or

the user of the Model 775 warming unit can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile

RF communications equipment (transmitters) and the Model 775 warming unit as recommended below, according to the maximum output power of the

communications equipment.

Rated maximum output power of

transmitter W

Separation distance according to frequency of transmitter m

150 kHz to 80 MHz

d = 1.2

80 MHz to 800MHz

d = 1.2

800 MHz to 2,5 GHz

d = 2.3

0,01

0.12

0.12

0.23

0,1

0.38

0.38

0.73

1

1.2

1.2

2.3

10

3.8

3.8

7.3

100

12

12

23

For transmitters rated at a maximum output power not listed above, the recommended separation distance

d

in meters (m) can be estimated using the

equation applicable to the frequency of the transmitter, where

P

is the maximum output power rating of the transmitter in watts (W) according to the

transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects

and people.

15

GB / 34-8718-8817-7

Physical Characteristics

DIMENSIONS

13” high x 13” deep x 14” wide (33 cm high x 33 cm deep x 36 cm wide)

WEIGHT

16 lb (7.3kg)

RELATIVE NOISE LEVEL

53 dBA (High fan setting)

48 dBA (Low fan setting)

HOSE

Flexible, compatible with the Model 241 blood/fluid warming set.

Length: 80” (203 cm)

UNIT INTAKE FILTER

MERV 14*

* See Frequently Asked Questions on Filtration (p. 58)

RECOMMENDED FILTER CHANGE

Every 12 months or 500 hours of use

MOUNTING

Can be clamped to an IV pole, placed on a hard surface, bed rail mount, or

mounted to the rolling cart accessory.

Temperature Characteristics

RECOMMENDED OPERATING ENVIRONMENT

TEMPERATURE:

15°C-25°C

HUMIDITY:

Max relative humidity 80% (up to 31°C) decreasing linearly to 50% relative

humidity at 40°C.

ALTITUDE:

Max 2,000m

TEMPERATURE CONTROL

Electronically controlled.

HEAT GENERATED

High fan setting:

1600 BTU/hr (average), 470 W (average)

Low fan setting:

1330 BTU/hr (average), 390 W (average)

OPERATING TEMPERATURES

Average temperatures at the end of the hose:

HIGH:

43° ± 1.5°C (109.4° ± 2.7°F)

MED:

38° ± 1.5°C (100.4° ± 2.7°F)

LOW:

32° ± 1.5°C (89.6° ± 2.7°F)

TIME TO REACH OPERATING TEMPERATURE

2 - 5 minutes (dependent on blanket model)

Time required for the contact surface temperature to heat up from 23 ± 2°C

to 37°C (73 ± 2°F to 99°F).

STORAGE/TRANSPORT TEMPERATURE

-20°C to 45°C (-4°F to 113°F)

Store all components in a cool, dry place when not in use.

SAFETY SYSTEM

THERMOSTAT

Independent electronic circuit; thermal cutoff shuts the heater

OFF to ensure hose end air remains below 46°C to 56°C; back-up

over-temperature detection at hose inlet.

ALARM SYSTEM

Over-temperature (46°C to 56°C): red

Over‑temp

indicator light flashes,

alarm sounds, heater and blower shut down, operating indicator lights

turn OFF, and the user can no longer adjust the warming unit using the

control panel.

FAULT:

Fault

indicator light flashes, alarm sounds.

OVERCURRENT PROTECTION

Dual input fused lines.

Electrical Characteristics

HEATING ELEMENT

1400 W Resistive

LEAKAGE CURRENT

Meets UL 60601-1 and IEC 60601-1 requirements.

BLOWER MOTOR

OPERATING SPEED:

4,700 rpm (high fan setting)

4,100 rpm (low fan setting)

AIRFLOW:

Up to 48 cfm or 23 L/s

POWER CONSUMPTION

Peak: 1550 W

Average: 800 W

POWER CORD

15 ft., SJT, 3 cond., 13 A

15 ft., SJT, 3 cond., 15 A

4.6 m, HAR, 3 cond., 10 A

DEVICE RATINGS

110-120 VAC, 50/60 Hz, 11.7 A, or

220-240 VAC, 50/60 Hz, 7.2 A, or

100 VAC, 50/60 Hz, 15 A

FUSES

TYPE:

Fast acting ceramic fuses, 250 VAC

AMP RATING:

12 A (110 - 120 VAC)

8 A (220 - 240 VAC)

15 A (100 VAC)

OPERATING SPEED:

F (Fast Acting)

BREAKING CAPACITY:

15 A, 12 A: 750 A @ 250 Vac

15 A, 12 A: 10,000 A @ 125 Vac

8 A: 200 A @ 250 Vac

8 A: 10,000 A @ 125 Vac

PDF Scaled at 75.0%