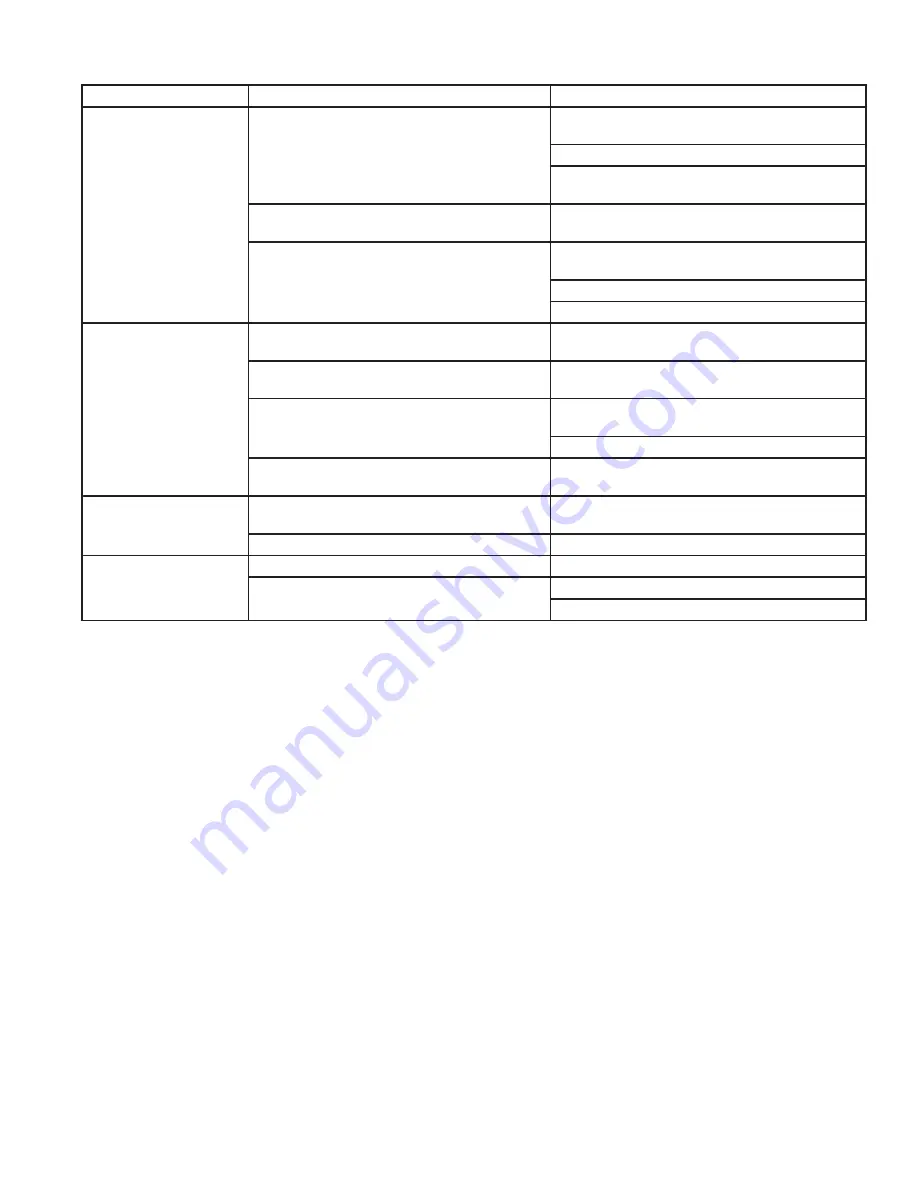

PROBLEM

CAUSE

SOLUTION

1

Excessive pressure drop

through fi lter

A

Filter not backwashing

1

Check motor by manually initiating a regeneration, re-

place as necessary

2

Check for uninterrupted power supply.

3

Check backwash frequency. Change program if neces-

sary.

B

Filter bed loaded with sand.

1

Verify sediment being reduced is less dense than the

fi lter media.

C

“Cementing” or “Channeling” of media.

1

Probe bed for this condition. Verify adequate pumping

rate for backwashing.

2

Check for frozen, plugged or restricted drain line.

3

Check for adequate backwash frequency.

2

Contaminant not being

properly reduced.

A

Leaking bypass valve.

1

Check bypass valve in “SERVICE” position. Repair or re-

place if necessary.

B

Internal valve leak.

1

Check piston and spacers and seals. Replace as neces-

sary.

C

Distributor not properly seated in control valve.

1

Make sure distributor is in tube adaptor protruding from

bottom of control valve.

2

Check distributor tube o-ring. Replace as necessary.

D

Flow rate too high for fi lter.

1

Check demand requirements against fi lter recommend-

ed fl ow rates.

3

Filter raises pH too high

(Neutralizer)

A

Filter is brand new.

1

Crack the bypass valve allowing some water to bypass

the unit.

B

Wrong media used.

1

Rebed unit.

4

Filter fails to raise pH

(Neutralizer)

A

Flow rates too high.

1

Verify demand rate does not exceed fi lter rating.

B

Filter bed cemented or channeled.

1

Verify adequate pumping rate for backwashing unit.

2

Check drain line for freezing, plugging or restrictions.

SECTION 4: TROUBLESHOOTING

4-1