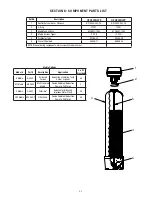

ONLY THOSE PARTS CIRCLED IN DRAWING ON PREVIOUS PAGE AND/OR LISTED BELOW ARE STOCK ITEMS.

ALL OTHERS ARE SPECIAL ORDER, NON-RETURNABLE.

BACKWASH CONTROL PARTS LIST

REF

PART NO>

DESCRIPTION

A

60351-00

Power Head Assy., Complete, L/Cover, 110V,60Hz (Incl. Ref. Items 1-27)

60351-04

Power Head Assy., Complete, L/Cover, 220V,50Hz (Incl. Ref. Items 1-27)

B

19231X

Skipper Wheel Assy. (incl. Ref. Items 4-9)

C

19235X

12-Hour Gear Assy. (Incl. Ref. Items 10-15)

D

14554X

Control Valve Body Assy. (Incl. Ref. Items 30-36 E & G)

E

60102-52

Piston Assembly

F

60125

Seal Kit (incl. Ref. items 32& 33)

G

60384X

Drain Line Flow Control Assy. (incl. Ref. Items 37-44)

H

10090X

Adapter Coupling Assy. (incl. Ref. Items 45-48)

J

60049/18706X

1" NPT Bypass Valve Assy. (incl. Ref. Items 49-58)

60049/18706-10X

1" BSP Bypass Valve Assy. (incl. Ref. Items 49-58)

26

19170

Motor, 110V, 60 Hz

18825

Motor, 220V,50Hz

27

11384

Motor Mtg. & Ground Screw

29

19171

Main Drive Gear

30

13547

Strain Relief - Flat Cord

31

11842

Power Cord, 110V,60Hz, US Plug

12972

Power Cord, 220V,50Hz, European Plug

38

13304

Distributor Tube O-Ring 1"

37

12281

Tank O-Ring

39

13303

Injector Cover O-Ring

40

13301

Injector O-Ring

41

13163

Injector/Drain Housing

42

13166

Injector Cover

43

13315

Injector Mtg. Screw

44

Drain Line Flow Control Button:

12092

5.0 GPM

12408

7.0 GPM

45

13173

Drain Line Flow Control Button Retainer

48

12338

Drain Line Fitting

47

13305

Coupling O-Ring

48

13709 Adapter

Coupling

49

13255

Adapter Clip

50

13314

Screw - Adapter Coupling

52

18660

O-ring

53

18661

O-ring (ORG-218)

55

18706

Adapter Yoke, 1" NPT

18706-10X

Adapter Yoke, 1" BSP

5-4