16

78-8124-5866-5-E

3M

™

Cold Shrink QT-lll Silicone Rubber Three Core Inverted Skirted Termination

with High-K Stress Relief

6.5 Install terminal lugs.

NOTE: Special Case – When lug spade dimension is larger than inside diameter of white plastic termination core,

position termination assemblies over cable phase legs prior to installing lugs.

Remove inner red shipping core from each termination assembly by pulling and unwinding the loose red

core ribbon. Position one termination over each cable phase leg. Each termination assembly must be

positioned with its loose white core ribbon end directed toward the open (cut) end of the cable. DO NOT

REMOVE CORE AT THIS TIME. Continue with lug installations.

a. For Aluminum Conductors - Thoroughly wire brush conductor strands to remove aluminum oxide

layer. Insert conductor into lug or connector and then remove conductor. This will transfer some of the

antioxidant paste onto the conductor. Wire brush the antioxidant paste into the strands. Immediately

insert conductor into terminal lug barrel as far as it will go.

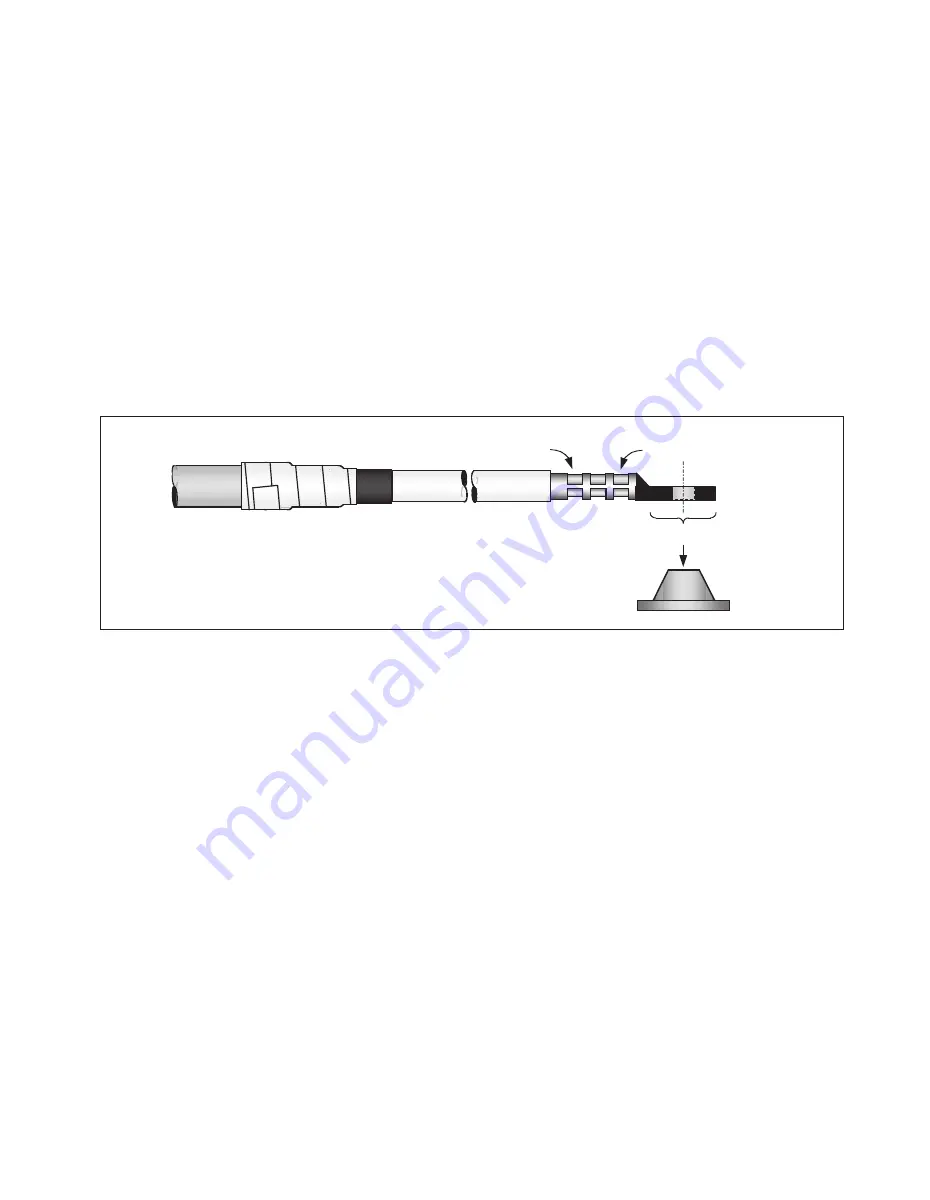

b. Ensure that each lug face is parallel to equipment bushing or lug connection interface (Figure 22).

Last Crimp

First Crimp

Figure 22

Note: Die/crimper rotation between consecutive crimps is RECOMMENDED.

c. Crimp terminal lug according to manufacturer recommendations. Start at the upper end as shown

(Figure 22). Remove all traces of oxide inhibitor that may have come out of lug barrel during crimping.

d. If abrasive must be used:

1. Use on insulation only. DO NOT USE ABRASIVE ON SEMI-CON INSULATION SHIELD!

2.

Use ONLY aluminum oxide abrasive; grit 120 or finer.

3. Be careful not to reduce the cable insulation diameter below that allowed by the kit.

e. Wipe the cable insulation and lug using a solvent wipe from supplied 3M Cable Cleaning Preparation

Kit CC-2, or an approved cable cleaner/solvent, AND ALLOW IT TO DRY BEFORE INSTALLING

TERMINATION. A clean lint-free cloth, inexpensive paper towel or 3M Cable Cleaning Pads CC-DRY

(not supplied with kit) can be used to dry the insulation surface if air drying time is of concern.

DO NOT ALLOW SOLVENT TO TOUCH SEMI-CON INSULATION SHIELD!