11

78-8124-5866-5-E

3M

™

Cold Shrink QT-lll Silicone Rubber Three Core Inverted Skirted Termination

with High-K Stress Relief

4.0 Install Silicone Rubber Breakout Boot Assembly

4.1

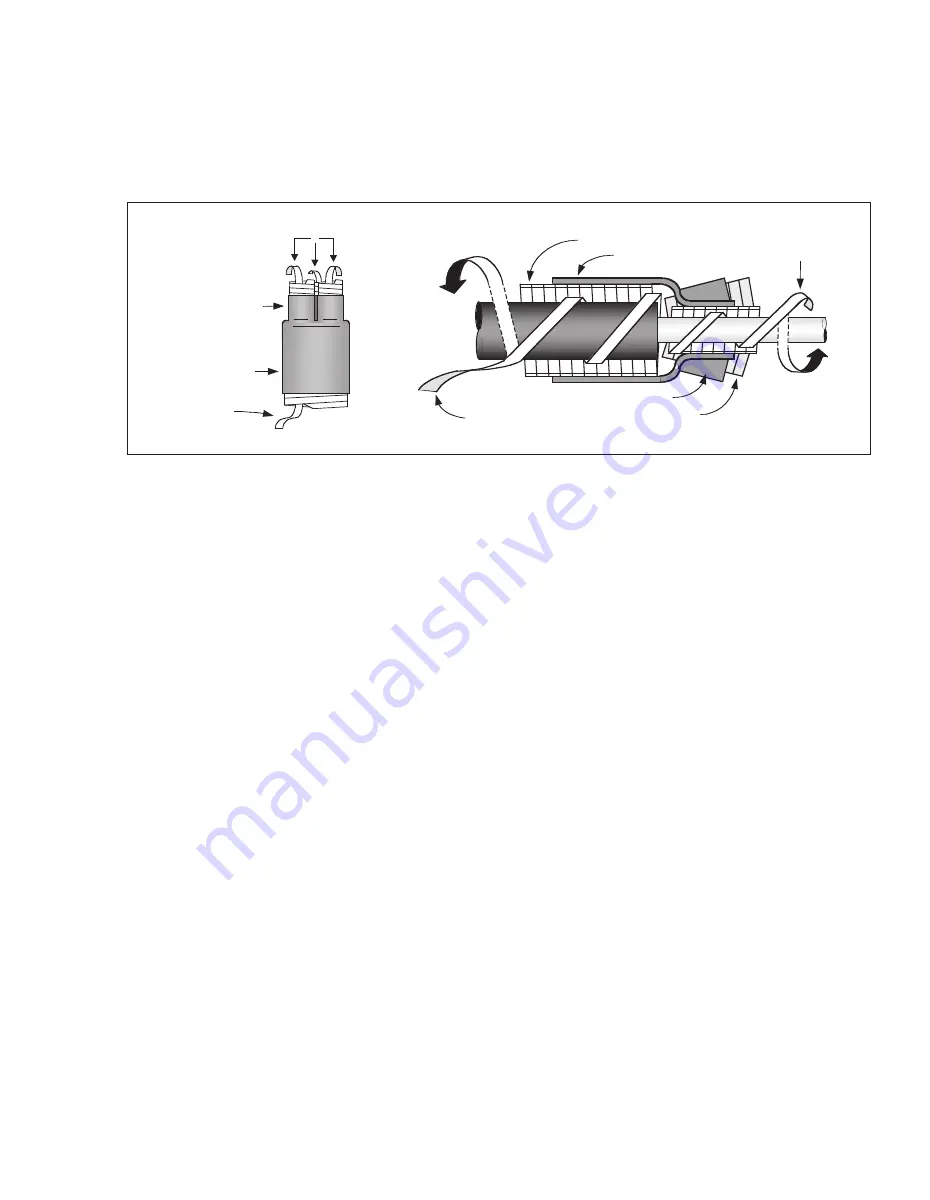

Inspect breakout boot assembly and confirm that all loose plastic core ends are free as shown (Figure 13).

Finger

Neck

Neck Core

Boot Neck

Loose Core Ends

Boot Finger

Finger Core

Loose Core End

Loose Core End

Loose Core End

Figure 13

4.2 To ensure that the breakout boot can be fully seated into the breakout area of the cable, it will be necessary to

unwind a few turns of each finger core.

Caution: Do not unwind too far such that boot fingers begin to collapse.

4.3 Hold loose neck-end core ribbon to one side so that it can not become trapped between cable phases. Slide

boot assembly over cable end; guiding individual cable cores through boot assembly fingers.

Hint: View end of cable through finger cores to ease cable phase insertion.

4.4 Slide breakout boot assembly onto cable as far as it will go. Large neck-end should fully extend over

previously installed jacket sealing assembly tube.

Hint: Spreading cable phases while sliding the boot assembly can ease the installation.

4.5 Remove large neck-end core. Grasping loose core ribbon end, pull and unwind counterclockwise around

cable.

4.6 Remove each finger core. Grasping loose core ribbon end, pull and unwind counterclockwise around each

cable phase leg.