16

•

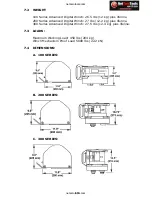

Check the digital counter,

(see Figure 11) if it

exceeds 30,000 cycles

from the last factory

service recorded in the

inspection log in Section 9,

return the winch to

DBI-SALA or an authorized

repair center for service.

•

Check operation of the

winch in high and low

speed positions; it must

crank up and down freely.

Stiff or rough operation

may indicate a worn gear

or bearing.

•

Inspect the Cable

Retaining Spring (see

Figure 1) assuring that it

applies pressure against

the line. If the plastic wear

pad needs to be replaced,

return the winch to an

authorized service center.

•

Inspect each system

component (support

structure, back-up fall

arrest system, body support, connectors, etc.) according to

manufacturer’s instructions.

5.3 LIFELINE INSPECTION

WIRE

ROPE:

Inspect entire length of wire rope assembly starting

at the hook. Always wear protective gloves when inspecting wire

rope.

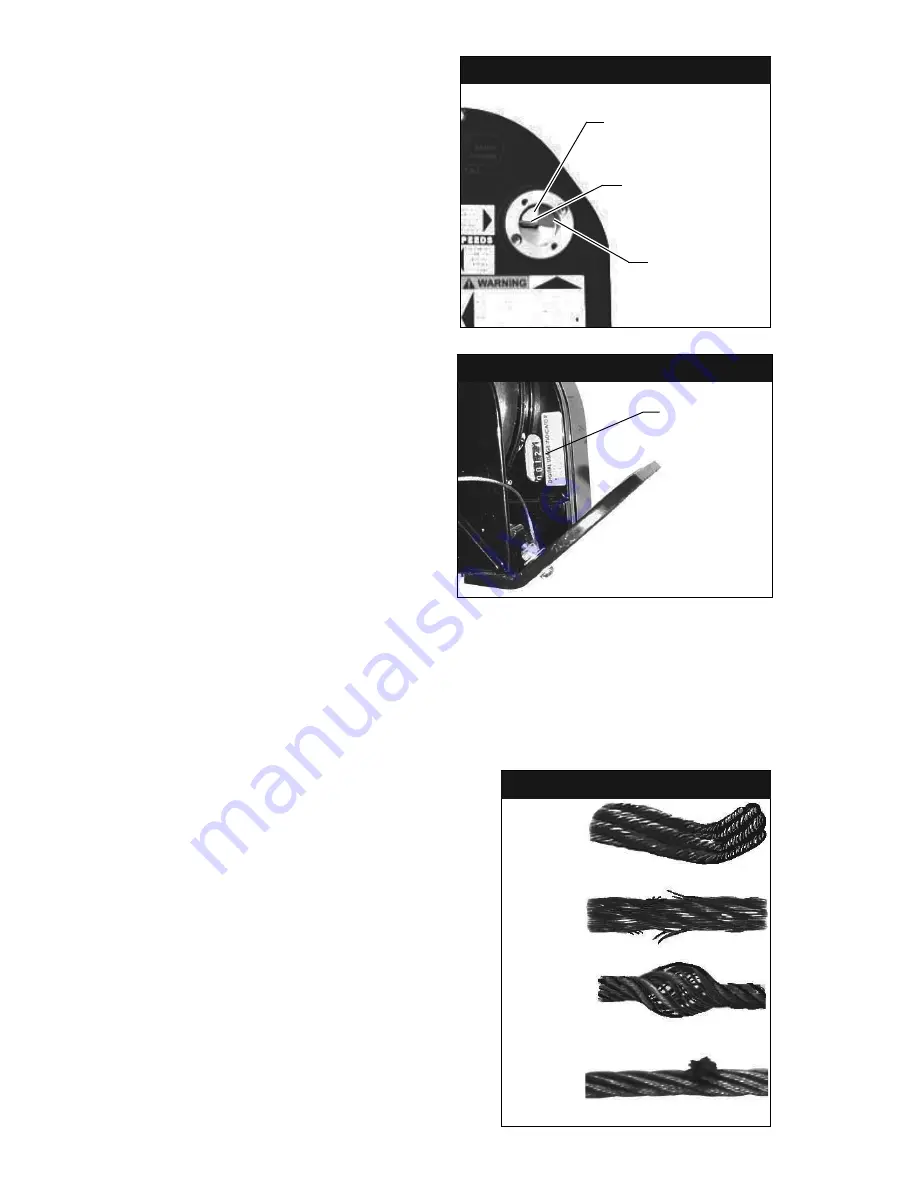

A.

Inspect for broken wires by

passing the wire rope through

gloved hands, flexing it every

few inches to expose breaks.

Broken wires can be removed

by bending the wire back

and forth parallel to the rope

length. Do not attempt to pull

wires out of rope. Inspect for

kinks, cuts, crushed burned

areas, or other damage (see

Figure 12). Wire rope with

serious damage must be

removed from service.

Figure 11 - Digital Counter

Digital

Counter

Bird-caging

Welding splatter

Kinked wire rope

Broken wires

Figure 12 - Wire Rope Flaws

Indicator Pin

Green Section

Red Section

Figure 10 - Brake Wear Indicator

netzerotools.com

netzerotools.com