10

4.0 USE

;

Never exceed the Capacity maximums specified in Table 1. Exceeding the stated capacity could collapse or tip the system, resulting

in serious injury or death.

4.1

BEFOrE EACH USE:

Verify that your work area and Personal Fall Arrest System (PFAS) meet all criteria defined in

Section 2 and a formal Rescue Plan is in place. Inspect the Glyde-Saf HD FAS per the ‘

User

’ inspection points defined on

the “

Inspection and Maintenance Log

” (Table 2). If inspection reveals an unsafe or defective condition, do not use the

Glyde-Saf HD FAS. Remove the system from service and contact 3M Fall Protection regarding replacement or repair.

;

SAFE WORK AREA

: Figure 2 illustrates the Safe Work Area for the Glyde-Saf HD Fall Arrest System. The gray shading on the table

designates safe working distances where the angle of the Lifeline is less than or equal to 30° from vertical. NEVER work at a Horizontal

Distance (H) and Vertical Distance (V) that results in a calculated Vertical Fall Distance (F) exceeding the gray shaded values on the

table in Figure 2.

4.2

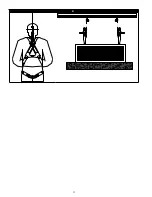

FALL ArrEST CONNECTIONS:

Figure 9 illustrates application of the Glyde-Saf HD Fall Arrest System and its Fall

Arrest Connections. The Glyde-Saf HD Fall Arrest System must always be used with a Full Body Harness and Fall Arrest

subsystem. Trolleys within Trolley Rails travel back-and-forth inside the Trolley Rail halves. A Self-Retracting Lifeline (SRL)

is connected to the eye on each Trolley. Connect the other end of the SRL to the back Dorsal D-Ring on the Harness.

A Tag Line can be attached to the SRL Lifeline and used to retrieve the lifeline for connection to the user’s harness.

;

No more than one person, meeting the Capacity requirements specified in Table 1, shall be attached to each Trolley.

5.0 INSPECTION

5.1

INSPECTION FrEQUENCY:

The Glyde-Saf HD Fall Arrest System must be inspected at the intervals defined in Section

1. Inspection procedures are described in the

“Inspection Checklist”

and

“Maintenance Log” (Table 2)

. Inspect all other

components of the Fall Protection System per the frequencies and procedures defined in the manufacturer’s instructions.

5.2 dEFECTS:

If inspection reveals an unsafe or defective condition, remove the Glyde-Saf HD Fall Arrest System from

service immediately and contact 3M Fall Protection regarding replacement or repair. Do not attempt to repair the

Fall Arrest System.

;

Only 3M Fall Protection or parties authorized in writing by 3M Fall Protection may make repairs to this equipment.

5.3

PrOdUCT LIFE:

The functional life of the System is determined by work conditions and maintenance. As long as the

product passes inspection criteria, it may remain in service.

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING:

Periodically clean The System with a soft brush, warm water, and a mild soap solution. Ensure parts are

thoroughly rinsed with clean water.

;

Although highly resistant to chemicals and environmental conditions, avoid contaminating the Flexiguard Anchorage System with

acids, bitumen, cement, paint, cleaning fluids, etc. If the equipment contacts acids or other caustic chemicals, remove from service and

wash with water and a mild soap solution. Inspect per Table 2 before returning to service.

6.2 SErVICE:

Only 3M Fall Protection or parties authorized in writing by 3M Fall Protection may make repairs to this

equipment. If the anchor has been subject to fall force or inspection reveals an unsafe or defective conditions, remove the

anchor from service and contact 3M Fall Protection regarding replacement or repair.

Summary of Contents for DBI SALA FLEXIGUARD Glyde-Saf HD System

Page 3: ...3 6 A B A B 50 ft 15 2 m 6 ft 1 8 m 6 ft 1 8 m 7 8 ...

Page 4: ...4 9 ...

Page 13: ......