3M

1

/

8

in. to

3

/

4

in. File Belt Sander

4

Revision 022514

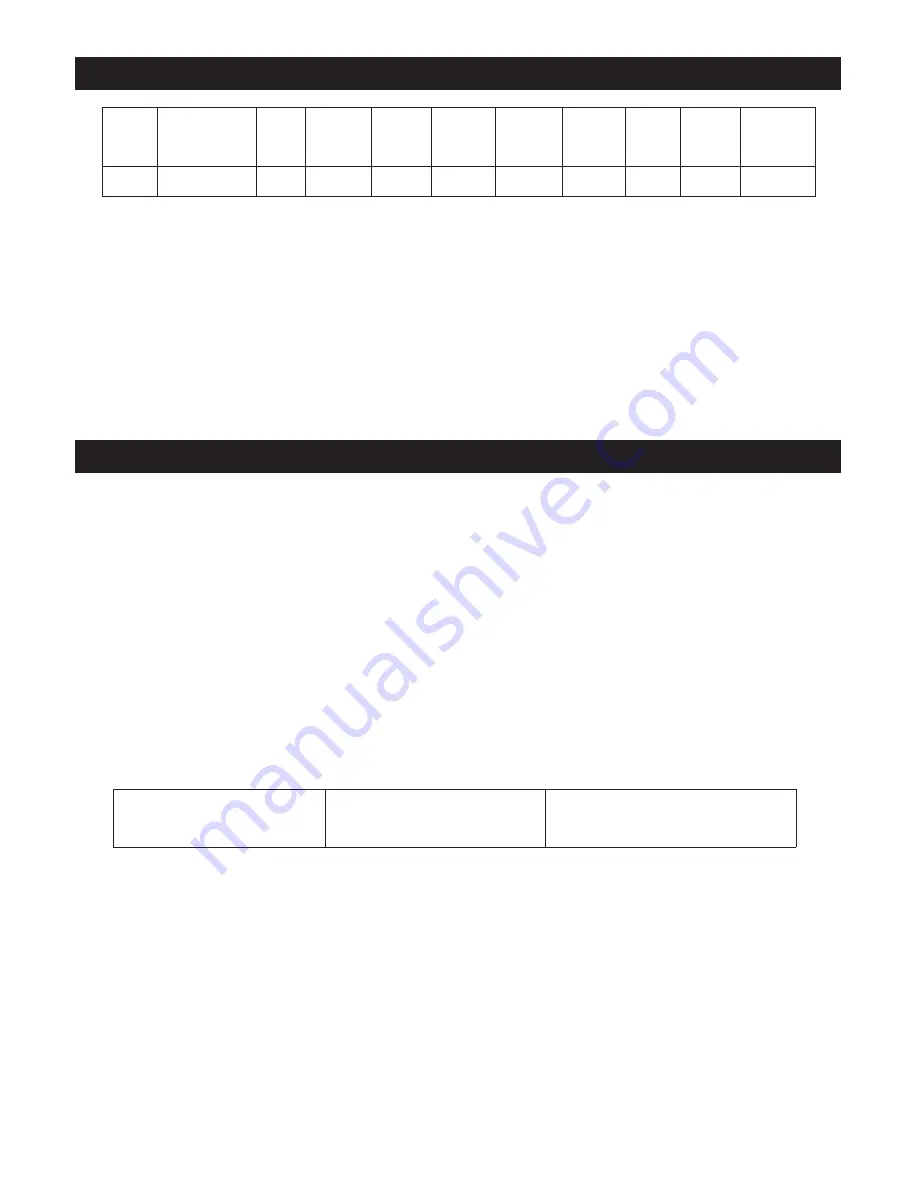

Recommended Airline

Size - Minimum

10 mm

3/8 in

Recommended Maximum

Hose Length

8 meters

25 feet

Air Pressure

Maximum Working Pressure 6.2 bar 90 psig

Recommended Minimum

NA

NA

Product Configuration/Specifications: 22,000 RPM File Belt Sander

*Declared noise levels; measurements carried out in accordance with standard EN ISO 15744:2008.

** Declared vibration levels in accordance with EN12096; measurements carried out in accordance with standard EN ISO 28662-1:1992; EN 60745-1:2006

and EN 60745-2-4:2007, except that feed force was reduced to 10N +/- 5N due to the impracticality of operating this small tool at 30N +/- 5N as stated in the

standard.

IMPORTANT NOTE: The noise and vibration values stated in the table are from laboratory testing in conformity with stated codes and standards and are not

sufficient risk evaluation for all exposure scenarios. The actual exposure values and amount of risk or harm experienced to an individual is unique to each situation

and depends upon the surrounding environment, the way in which the individual works, the particular material being worked, work station design, as well as

upon the exposure time and the physical condition of the user. 3M™ cannot be held responsible for the consequences of using declared values instead of actual

exposure values for any individual risk assessment.

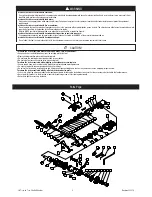

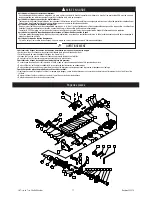

Operating / Maintenance instructions

PRIOR TO THE OPERATION

The tool is intended to be operated as a hand held tool. It is always recommended that while using the tool, operators stand on a solid floor, in a secure position

with a firm grip and footing. Be aware that the sander can develop a torque reaction. See the section “SAFETY PRECAUTIONS”.

Use a clean lubricated air supply that will give a measured air pressure at the tool of 6.2 bar (90 psig) when the tool is running with the lever fully depressed. It

is recommended to use an approved 10 mm (

3

/

8

in) x 8 m (25 ft) maximum length airline. Connect the tool to the air supply as shown in Figure 1. Do not connect

the tool to the airline system without an easily accessible air shut off valve. It is strongly recommended that an air filter, regulator and lubricator (FRL) be used

as shown in Figure 1 as this will supply clean, lubricated air at the correct pressure to the tool. In any case appropriate air pressure regulators shall be used

at all times while operating this tool where the supply pressure exceeds the marked maximum of the tool. Details of such equipment can be obtained for your

tool distributor. If such equipment is not used, the tool should be manually lubricated. To manually lubricate the tool, disconnect the airline and put 2 to 3 drops

of suitable pneumatic motor lubricating oil such as 3M™ Air Tool Lubricant PN 20451, Fuji Kosan FK-20, Mobil ALMO 525 into the hose end (inlet) of the tool.

Reconnect tool to the air supply and run tool slowly for a few seconds to allow air to circulate the oil. If the tool is used frequently, lubricate it on a daily basis or

lubricate it if the tool starts to slow or lose power. It is recommended that the air pressure at the tool be 6.2 bar (90 psig) while the tool is running so the maximum

RPM is not exceeded. The tool can be run at lower pressures but should never be run higher than 6.2 bar (90 psig). If run at lower pressure the performance of the

tool is reduced.

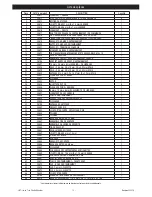

Model

Number

Belt Size

in. (mm)

Motor

Speed

(RPM)

Belt Speed

SFPM (smm)

Product

Net Wt

lb (kg)

Height

in. (mm)

Length

in. (mm)

Width

in. (mm)

*Noise

Level dBA

Pressure

(Power)

**Vibration

Level m/s

2

(ft/s

2

)

**Uncertainty

K

m/s

2

28366

1

/

8

-

3

/

4

x 18-24

(3-19 x 457-610)

22,000

4990 (1521)

2.8 (1.3)

2.93 (74.5)

14.57 (370)

5.95 (151.2)

81 (90)

<2.5 (<8.2)

N/A