17

18

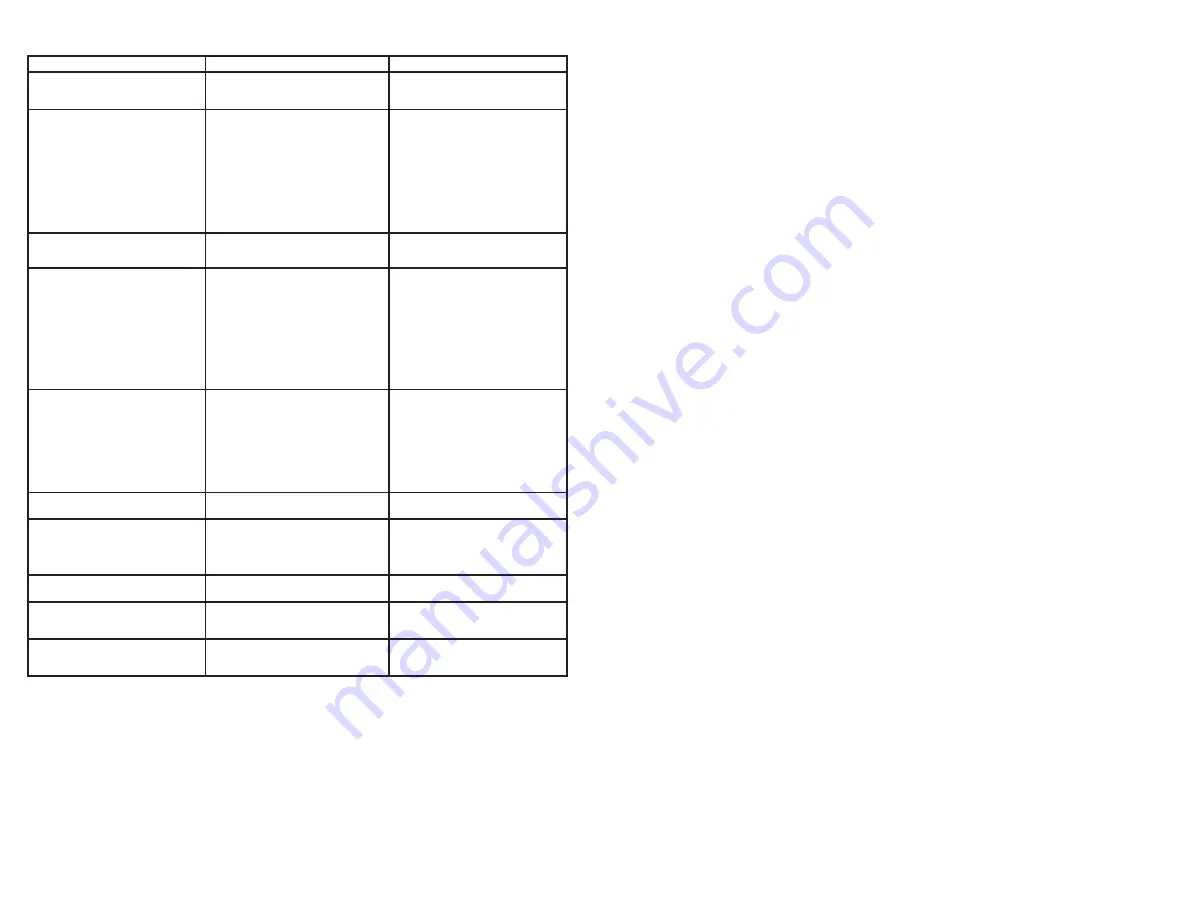

TROUBLESHOOTING

Use the table below to help identify possible causes and corrective action for problems you may experience.

Problem

Possible Cause

Corrective Action

You smell or taste contaminants or an

irritation occurs

Misuse, improper assembly or malfunction of

equipment.

Leave work area immediately and contact

your supervisor. Do not use the PAPR until

the cause is identified and corrected.

Dizziness occurs

Gases or vapors broke through the chemical

cartridge.

The gas and vapor cartridge being used is

incorrect for your workplace contaminants.

Airflow too low.

Inlet and outlet gaskets are in poor condition.

Leave work area immediately.

Change gas and vapor cartridge.

Refer to respirator decision logic such as

ANSI Z88.2-1992 or 3M respirator selection

guide or consult an industrial hygienist.

Perform an airflow check and troubleshoot if

PAPR fails airflow test.

Replace gaskets.

GVP-111 battery pack recharge light

remains “on”

The charger has malfunctioned.

The battery has a dead cell(s).

Replace charger and charge battery.

Replace battery pack.

Blower does not run when switch is

depressed

Battery is discharged.

Power cord disconnected.

Faulty power switch.

Faulty power cord.

Faulty motor.

Leave work area immediately.

Recharge battery.

Secure the power cord to the motor blower

and battery.

Replace battery pack.

Replace power cord.

Replace motor blower.

PAPR fails airflow test

Clogged filter.

Battery pack needs charging.

Inlet and/or outlet gaskets are worn/damaged

or missing.

Motor blower malfunction.

Breathing tube restricted.

Replace filter.

Charge battery.

Inspect and replace if necessary (GVP-101).

Replace motor blower unit (GVP-100).

Remove restriction.

BP-15 battery pack does not work after

charging

Low voltage detection circuit has not reset.

Recharge for short period of time.

BC-200 or BC-210 does not work, charge

adapter indicator is steady yellow

BP-15 battery pack is too hot or too cold for

charging.

Incorrect battery pack is connected to the

charger.

Allow battery pack and charger

temperatures to moderate to between 50°F

(10°C) and 90°F (32°C).

Select the correct charger for the battery.

BC-200 or BC-210 does not work, power

base indicator is steady yellow

Too many chargers are chained together. The

maximum number allowed is ten (10).

Remove excess chargers.

BC-200 or BC-210 does not work, no

lights illuminated on power base or charge

adapter

Fuse on power base has blown.

Determine cause of the blown fuse and

replace with like fuse.

BC-200 or BC-210 does not work, the

charge adapter indicator is red or is not

illuminated

Incorrect battery pack is connected to the

charger. The BC-210 is only to be used with

the BP-15 battery pack.

Select the correct charger for the battery

pack.

For troubleshooting of the TR-630 Battery and available chargers please refer to Refer to the

User Instructions

for 3M™ Versaflo™ Battery and

Chargers TR-600 and Technical Data Bulletin #223 on Battery Maintenance for 3M™ Versaflo™ Respirator Systems.

For troubleshooting of the TR-659 battery adapter please refer to the TR-659 battery adapter

User Instructions

.

IMPORTANT NOTICE

WARRANTY:

In the event any 3M™ PSD Product is found to be defective in material, workmanship, or not in conformation with any express

warranty for a specific purpose, 3M’s only obligation and your exclusive remedy shall be, at 3M’s option, to repair, replace or refund the

purchase price of such parts or products upon timely notification thereof and substantiation that the product has been stored, maintained and

used in accordance with 3M’s written instructions.

EXCLUSIONS TO WARRANTY: THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OR CONDITION OF QUALITY, EXCEPT OF TITLE AND

AGAINST PATENT INFRINGEMENT.

Limitation of Liability:

Except as provided above, 3M shall not be liable or responsible for any loss or damage, whether direct, indirect,

incidental, special or consequential, arising out of sale, use or misuse of 3M PSD products, or the user’s inability to use such products. THE

REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.