3

4

NIOSH Cautions and Limitations

A – Not for use in atmospheres containing less than 19.5 percent oxygen.

B – Not for use in atmospheres immediately dangerous to life or health.

C – Do not exceed maximum use concentrations established by regulatory standards.

F – Do not use powered air-purifying respirators if airflow is less than four cfm (115 lpm) for tight fitting facepieces or six cfm (170 lpm) for

hoods and/or helmets.

H – Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridge and canisters are replaced before

breakthrough occurs.

I – Contains electrical parts that may cause an ignition in flammable or explosive atmospheres.

J – Failure to properly use and maintain this product could result in injury or death.

L – Follow the manufacturer’s

User’s Instructions

for changing cartridges, canister and/or filters.

M – All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA, OSHA, and other applicable regulations.

N – Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer.

O – Refer to

User’s Instructions

, and/or maintenance manuals for information on use and maintenance of these respirators.

P – NIOSH does not evaluate respirators for use as surgical masks.

Intrinsic Safety Approval

3M™ Motor Blower GVP-100, 3M™ Power Cord GVP-110 and 3M™ Battery Pack GVP-111 combination has been tested and classified by

Underwrites Laboratory (UL) for intrinsic safety for the following: Division 1, Class I; Group D, Class II, Groups E, F, G and Class III.

W

WARNING

Each person using this respirator assembly must read and understand the information in these

User Instructions

before use. Use of these

respirators by untrained or unqualified persons, or use that is not in accordance with these

User Instructions

,

may adversely affect

respirator performance and result in sickness or death.

Do not use with parts or accessories other than those manufactured by 3M as described in these

User Instructions

or on the NIOSH Approval

Label for this respirator. Do not attempt to repair or modify any component of the system except as described in these

User Instructions

.

Failure to do so

may adversely affect respirator performance and result in sickness or death.

OPERATING INSTRUCTIONS

Unpacking

Inspect the package contents for shipping damage and ensure all components are present. The product should be inspected before each use

following the procedures in the “Inspection” section of these

User Instructions

.

W

WARNING

Always correctly use and maintain the lithium-ion battery packs.

Failure to do so may cause fire or explosion or could adversely affect

respirator performance and result in injury, sickness, or death.

a. Do not charge batteries with unapproved chargers, in enclosed cabinets without ventilation, in hazardous locations, or near sources

of high heat.

b. Do not immerse without the battery storage and cleaning cover installed.

c. Do not use, charge, or store batteries outside the recommended temperature limits.

d. Charge in an area free of combustible material and readily monitored.

To reduce exposure to hazardous voltage:

a. Do not attempt to service the chargers. There are no user-serviceable parts inside.

b. Do not substitute, modify or add parts to the chargers.

c. Inspect the chargers and power cords before use. Replace if any parts are damaged.

d. Do not use the chargers outdoors or in wet environments.

CAUTION

The 3M™ GVP when used with the BP-15 battery pack or the TR-630 and TR-659 battery/adapter combination

IS NOT an intrinsically

safe system.

3M™ Motor Blower GVP-100, 3M™ Power Cord GVP-110 and 3M™ Battery Pack GVP-111 combination has been tested and classified by UL

for intrinsic safety for the following: Division 1, Class I; Group D, Class II, Groups E, F, G and Class III. If the GVP-111 battery case is compromised

or cracked, or if the rubber switch boot is damaged or missing, the battery pack and system should no longer be considered intrinsically safe.

To reduce the risks associated with hot surfaces:

- Do not touch pins after battery has been charged.

Assembly

Charge the battery pack:

1. Inspect the battery pack prior to each charge cycle. If the case is damaged do not charge the battery pack. Properly dispose of the battery

pack and replace.

2. Charge the battery pack in a cool, well ventilated location free of airborne contamination.

3. Plug the charger lead into the battery pack or place battery pack on charging cradle.

•

BP-15 battery pack:

Plug the charger power cord into an AC source (110-210 VAC). Refer to BC-210/BP-15

User Instructions

. The

BP-15 battery pack should be charged immediately upon receipt and stored on the charger between uses. If the BP-15 will be stored

off the charger, it should be fully charged initially and then fully recharged once every three months if not used sooner. For long-term

storage, 3M recommends the BP-15 be stored connected on an active charger. The BC-210 charger is used to charge the BP-15

battery pack.

NOTE:

The BC-210 charger is discontinued and no longer available.

•

GVP-111 battery pack:

Plug the charger power cord into an AC source (110-120 VAC). Refer to GVP-111

User Instructions

.

NOTE:

The GVP-111 should be charged for a minimum of 20 hours before initial use. The GVP-111 battery pack should not be left

continuously connected to the charger for more than 1 week as over time this may damage the battery pack cells. The GVP-112

charger is used to charge the GVP-111 battery pack.

•

TR-630 battery pack:

Plug the charger power cord into an AC source (100-240 VAC). When using the lithium-ion battery refer to the

User Instructions

provided with the battery. Refer to NIOSH Approval Label to see list of approved headgear and filter/cartridges that can

be used with this battery. The TR-630 should be charged immediately and fully upon receipt and may remain connected to the charger

indefinitely. The 3M™ Versaflo™ Single Station Battery Charger Kit TR-641N and 4-Station Battery Charger Kit TR-644N are used to

charge the TR-630 battery pack.

Both the BP-15 and GVP-111 battery packs and the TR-659 battery adapter (used with the TR-630 battery) have a red warning light indicating

the battery pack requires recharging. The red light is not a low air flow indicator.

Immediately exit the contaminated area when the visual

alarm (LED indicator light) on the adapter activates.

Users should also refer to 3M Technical Data Bulletin #178 – Maintenance and Care of 3M™ Powered Air Purifying Respirator (PAPR) Batteries

and to 3M Technical Data Bulletin #223 on Battery Maintenance for 3M™ Versaflo™ Respirator Systems for more information

.

Install the Battery Pack

•

BP-15 battery pack:

Plug the 3 prong plug end of the GVP-210 power cord into the top of the BP-15 battery pack.

•

GVP-111 battery pack:

Plug the single prong plug end of the GVP-110 power cord into the top of the GVP-111 battery pack.

•

TR-630 battery pack:

Please refer to guidance below for TR-630 battery, TR-659 battery adapter and holster assembly and installation.

•

For all battery packs:

Plug

the socket end into the prong receptacle on the front of the GVP-100 motor blower. (See diagram in

“Components, Accessories and Replacement Parts” in these

User Instructions

).

NOTE:

Take care to prevent the power cord from being hooked on protruding objects.

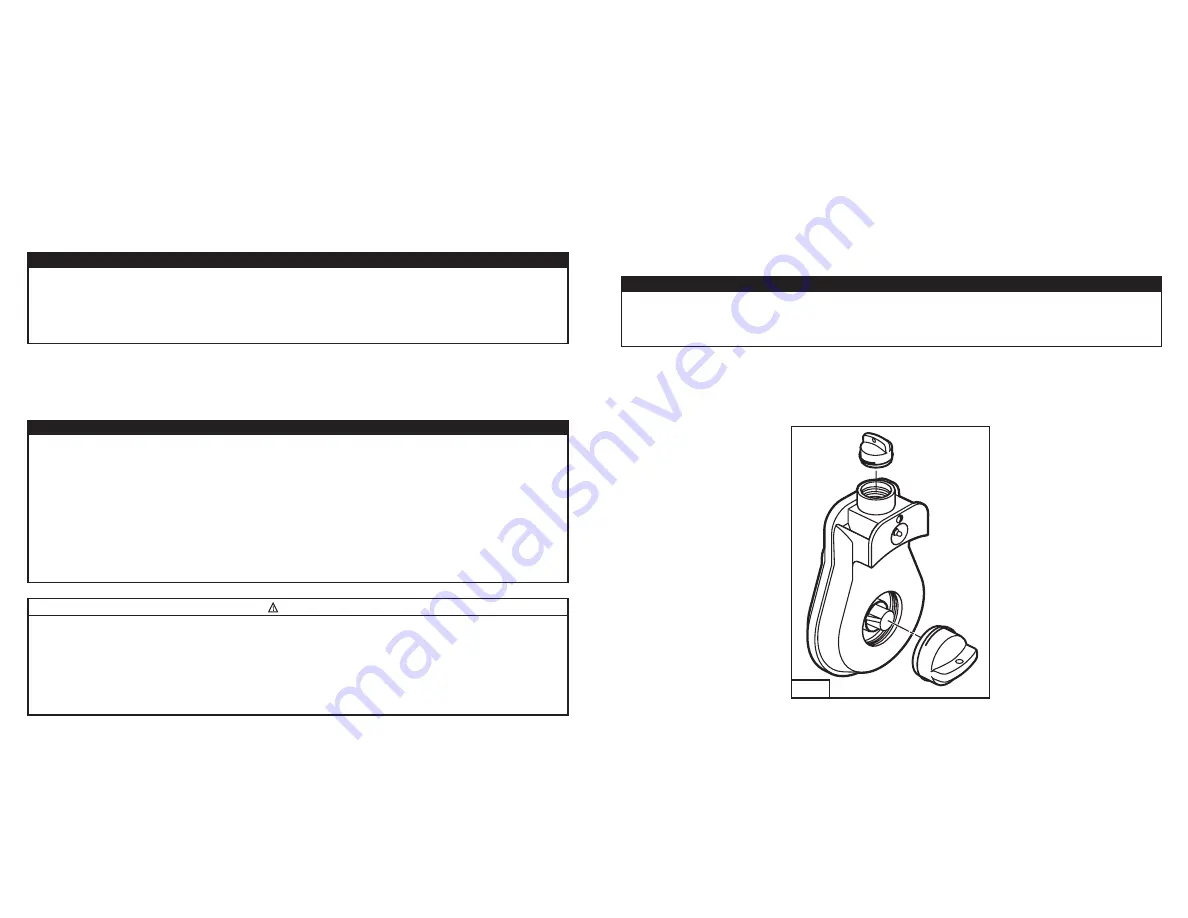

Filter/Cartridge Assembly

W

WARNING

Be certain that the filter and/or cartridge that you are placing on the unit is appropriate for the contaminants to which you will be exposed.

Failure to do so may result in sickness or death.

Do not over-tighten filter/cartridge. Over-tightening may result in distortion or displacement of the seal and may allow contaminated air to

enter the respirator headpiece and

may result in sickness or death.

1. Remove the plastic caps from the cartridge/filter.

2. Inspect the cartridge/filter for damage to the threads, plastic body or filter media. Discard if damaged.

3. Remove inlet and outlet motor/blower plugs as shown. Retain the plugs for used during cleaning (Fig. 1).

4. Inspect the gaskets in the inlet and outlet ports for cracks or excessive wear. Replace if missing or damaged.

5. Secure the cartridge/filter into the inlet of the motor/blower unit by hand tightening. The spark arrestor should be used for welding and all

situations where the GVP PAPR may be exposed to sparks, molten metal or other hot particulates.

Fig. 1