13

14

Chargers:

1. GVP-112:

- Input: 110-120 Volts AC

- Output: 7.5 VDC; 0.75 A

2. BC-210:

- Input: 100-220 VAC

- Output: 12 VDC; 4 A

3. TR-641N (TR-941N Power Supply):

- Input: 100-240V; 50-60 Hz; 1.5A

- Output: 19V; 2.37A

4. TR-644N (TR-944N Power Supply):

- Input: 100-240V; 50-60 Hz; 2A

- Output: 19V; 7.89A

Approximate Weights:

1. GVP PAPR: 1.1 lbs (0.5 kg)

2. GVP PAPR with HE filter: 1.6 lbs (0.72 kg)

3. GVP PAPR with OV cartridge: 2.6 lb (1.2 kg)

4. GVP PAPR with AG cartridge: 2.9 lbs (1.3 kg)

5. GVP PAPR with OV/HE cartridge: 3.1 lbs (1.4 kg)

6. GVP PAPR with AG/HE cartridge: 3.4 lbs (1.5 kg)

7. GVP PAPR with OV/AG cartridge: 2.6 lbs (1.2 kg)

8. GVP PAPR with OV/AG/HE cartridge: 3.1 lbs (1.4 kg)

9. GVP-111 battery pack: 2.5 lbs (1.1 kg)

10. BP-15 battery pack: 1.8 lbs (0.83 kg)

11. TR-630 battery pack with TR-659 adapter: 1.3 lb (0.6 kg)

PAPR System:

1. Noise Level (excluding exterior noise): Less than 80 dBA

2. Operating Temperature: 10°F to 120°F (-12°C to 49°C)

3. Estimated Motor Life: 2000 hours dependent on use conditions

Intrinsic Safety:

• GVP PAPR Assembly with GVP-111 battery pack is tested and classified intrinsically safe by UL for Division 1, Class I; Group D, Class II,

Groups E, F, G and Class III. If the GVP-111 battery pack case is compromised or cracked, or if the rubber switch boot is damaged or

missing, the battery pack should no longer be considered intrinsically safe.

• GVP PAPR Assembly with BP-15 battery pack is

NOT intrinsically safe

• GVP PAPR Assembly with TR-630 battery pack is

NOT intrinsically safe

Assigned Protection Factors (APF)

Refer to the

User Instructions

for the specific headgear to be used to determine the assigned protection factor for the GVP PAPR system.

Consult 3M Technical Data Bulletin #175 for further information on APFs and supporting test data.

HE Filter Service Life

The HE filter must be changed when the air flow as shown by the air flow indicator falls below 6 cfm or the HE filter becomes excessively dirty,

damaged, or wet.

Chemical Cartridge Service Life

Service life for chemical cartridges will vary depending on the contaminant, concentration and environmental conditions (temperature,

humidity). The 3M Service Life Software can help estimate service life for chemical cartridges.

COMPONENTS, ACCESSORIES AND REPLACEMENT PARTS

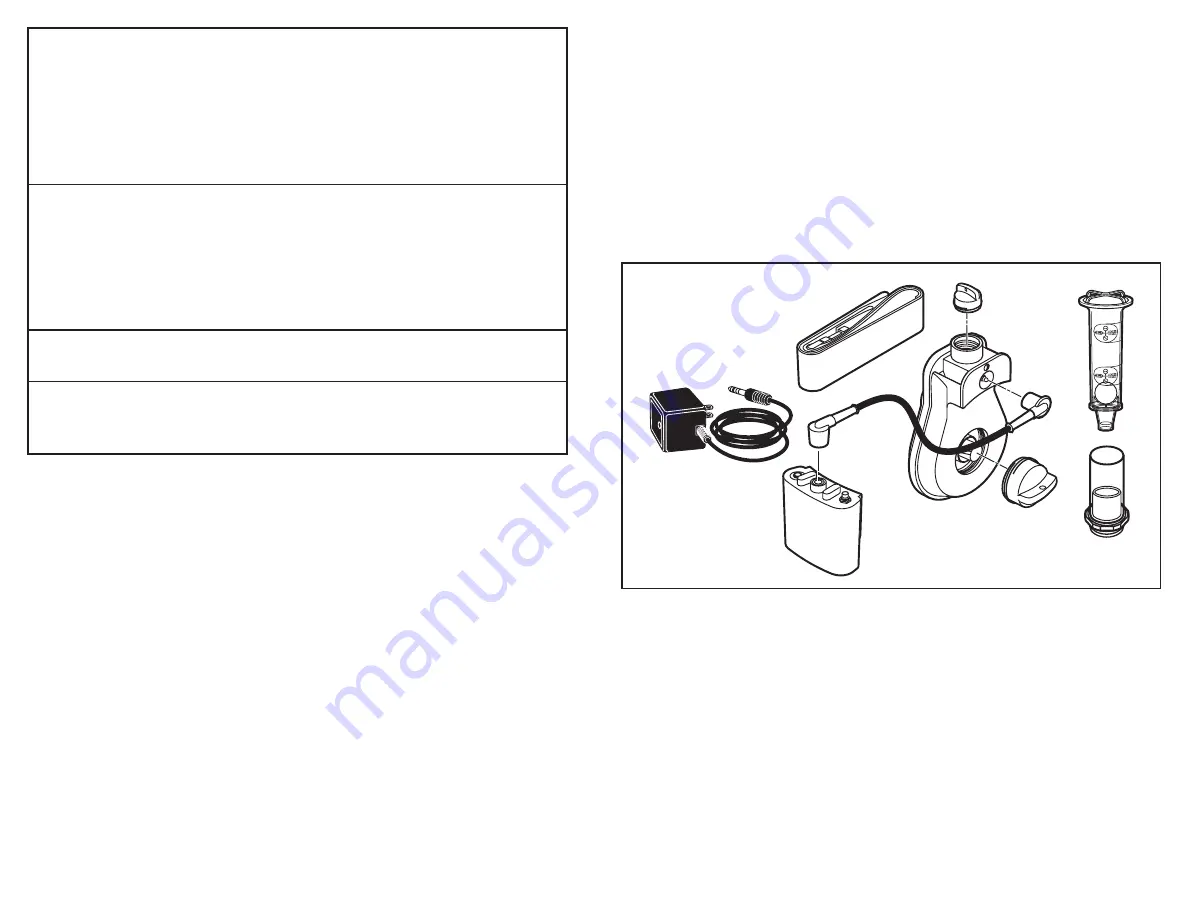

GVP-1:

Includes GVP-100 motor/blower, GVP-111 battery, GVP-112 charger, GVP-127 web belt, GVP-113 flow meter, GVP-181 L-Series flow

adapter, GVP-110 power cord and GVP-115 plugs

GVP-1U:

GVP-1 with GVP-117 urethane belt

GVP-CB:

GVP-1 with CB-1000 comfort belt

GVP-1 Intrinsically Safe System

a. PAPR Unit (Motor/Blower) GVP-100

b. Power Cord GVP-110

c. Battery Pack GVP-111

d. Charger GVP-112

e. Flow Meter GVP-113

f. Blower Plugs GVP-115 (inlet and outlet)

g. Web Belt GVP-127

h. Flow Meter Adapter L-181

GVP Series Assemblies Not Shown:

GVP-1U: GVP-1 with Urethane Waist Belt GVP-117

GVP-CB: GVP-1 with Comfort Belt CB-1000

GVP optional parts not shown:

• Urethane Waist Belt GVP-117

• Urethane Shoulder Strap GVP-118

• Web Shoulder Strap GVP-128

• Comfort Belt CB-1000

• Spark Arrest Cover GVP-146

• Adapter V-199 for approved BT series breathing tubes

d

g

f

f

a

b

c

e

h

Filters/Cartridges

GVP-441

Organic Vapor/HE (OV/HE)

GVP-442

Acid Gas/HE (HC/CL/SD/CD/HF/HE)

GVP-443

Organic Vapor/Acid Gas/HE (OV/HC/CL/CD/SD/HF/HS/HE)

GVP-444

Ammonia/Methylamine/HE (AM/MA/HE)

GVP-445

Formaldehyde/HE (FM/HE)

GVP-440

High Efficiency (HE)