Liquid

Outlet

or Inlet

Vacuum or

Sweep Gas

Vacuum or

Sweep Gas

Liquid

Outlet

or Inlet

Liquid

Outlet

or Inlet

Vacuum or

Sweep Gas

Vacuum or

Sweep Gas

Liquid

Outlet

or Inlet

Steps:

1. Mount contactor as shown below.

2. Refer to start-up procedures below for each mode of operation.

Notes:

•

The liquid pressure should always be higher than the gas pressure inside the contactor.

•

Liquids entering the membrane contactor should be prefiltered at 5 micron absolute at

99.9% removal (beta 1000).

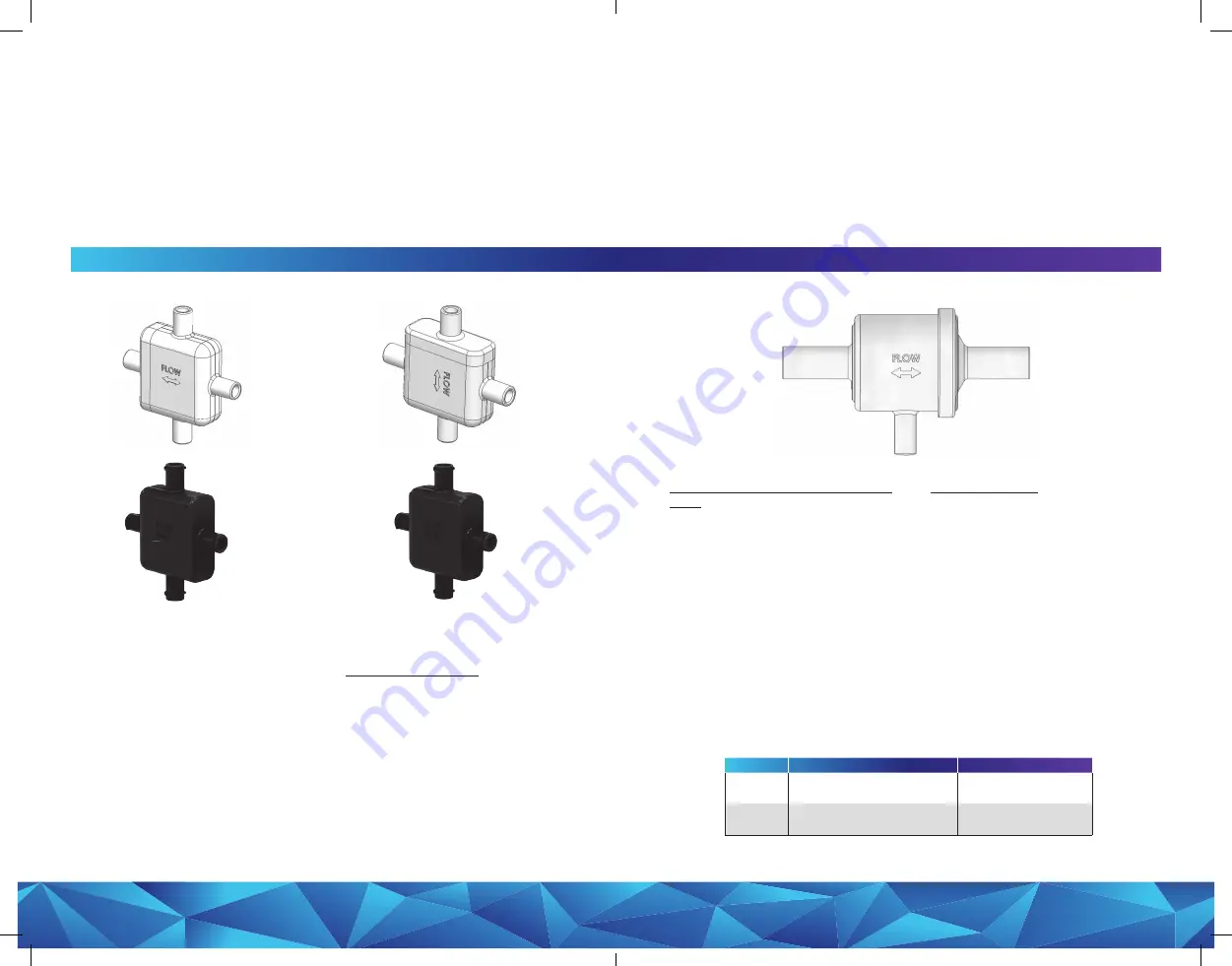

Correct Mounting Position and Port Identification

Start-up Procedures

| 3M

™

Liqui-Cel

™

MM 0.5x1 and 0.75x1 Series Membrane Contactors

MM-0.5x1 Series

Polycarbonate Housing

Polyethylene Housing

Sweep (Strip) Gas with Vacuum (Combo)

Mode

(applies only to the 0.5 x 1 Contactor)

1. Set the gas delivery pressure to the

contactor at ≤ 1 psig (0.07 barg).

2. Connect sweep gas to contactor via one of

the ports marked Vacuum or Sweep Gas.

3. Start sweep flow and adjust flow rate by

adjusting the appropriate valve. Typical

sweep flow rate range for 0.5x1 in

combo mode is 10-100 Std cc/min.

4. Connect vacuum to the contactor via

the second port marked Vacuum or

Sweep Gas.

5. Start vacuum pump.

6. Adjust absolute gas pressure on vacuum

side to desired level.

Vacuum Only Mode

1. Start vacuum pump following vacuum

pump manufacturer's instructions.

2. Apply vacuum to the membrane

contactor by opening the appropriate

valve. For MM-0.5x1 series membrane

contactors, vacuum can be applied to

both gas ports together, or to one port

while keeping the other port capped off.

3. Adjust absolute gas pressure on the

vacuum side to the desired level at the

vacuum port on the contactor.

Vacuum or

Sweep Gas

Liquid Outlet

or Inlet

Liquid Outlet

or Inlet

Vacuum or

Sweep Gas

Vacuum or

Sweep Gas

Liquid Outlet

or Inlet

Liquid Outlet

or Inlet

Vacuum or

Sweep Gas

Start-up Procedures

A. General start-up instructions for the

liquid phase.

Note:

Liquid flows on the shellside. The liquid

pressure should always be higher than the gas

phase pressure inside the contactor.

1. Connect the liquid in/out ports and the

vacuum/sweep ports as shown in the

diagrams above.

2. Slowly introduce liquid to the contactor,

making sure that the liquid inlet pressure

and liquid flow rate through the

contactor never exceed the respective

maximum operating limits.

B. General start-up instructions for the

sweep (strip) gas and vacuum phase.

Sweep (Strip) Gas Mode

(applies only to the 0.5 x 1 Contactor)

1. Set the gas pressure in the contactor to the

lowest possible level by adjusting the

appropriate valve in the gas delivery system.

2. Set the recommended sweep flow rate

by adjusting the appropriate valves. The

typical sweep gas flow rate range for the

0.5 x 1 is 50-500 std. cc/min.

3. Introduce sweep gas into the contactor.

Note:

If using compressed air, make sure

it is oil free and air temp is < 35°C. A 0.2

micron filter is recommended with any gas.

•

Gas entering the contactor should be filtered at 0.2 micron absolute at 99.9% removal

(beta 1000) for high-purity applications. Filtration at 1 micron absolute at 99.9% removal

(beta 1000) may be sufficient for industrial applications.

•

Upon initial start-up, flush all pipes to drain prior to introducing liquid into the membrane

contactors.

•

The vacuum pump and/or sweep gas should be on at all time unless the membrane

contactors are completely drained.

•

Liquid flows on shell side and sweep or vacuum are applied to the lumen side for these

3M Liqui-Cel MM-Series Membrane Contactors.

Liquid Inlet or

Outlet

Liquid Outlet

or Inlet

Vacuum

MM-0.75x1 Series

(Can only be operated in vacuum mode.)

Product

Maximum Pressure*

Maximum Flow Rate

0.5 x 1

3.1 barg, 25°C

(45 psig, 77°F)

30 ml/min

0.75 x 1

3.1 barg, 25°C

(45 psig, 77°F)

200 ml/min

* using 50 torr (mm Hg) vacuum on lumenside.